Description

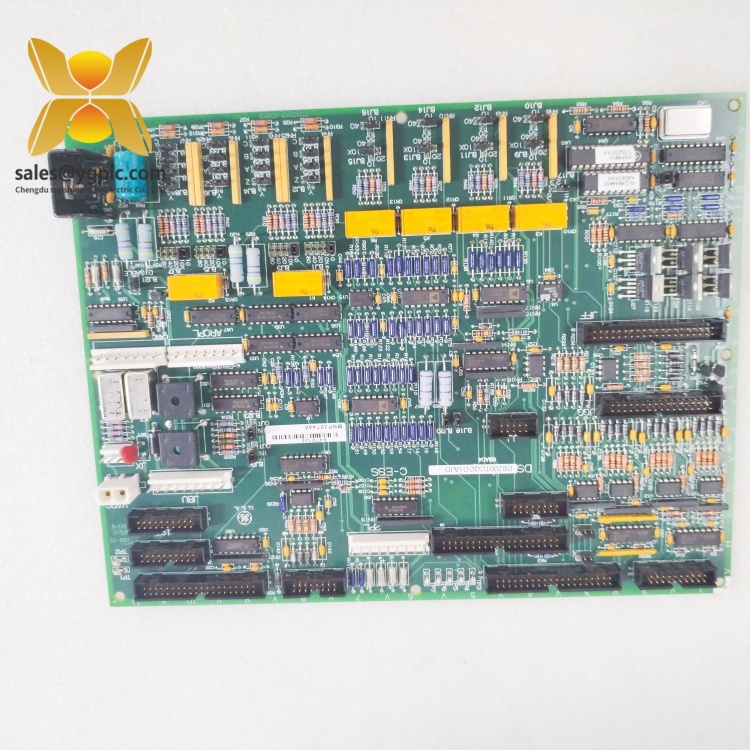

Product Overview — GE DS200TCQCG1AJD

The GE DS200TCQCG1AJD is a critical industrial control module belonging to GE’s Mark V series turbine control systems, specifically designed as an RST overflow board for analog I/O expansion and signal processing in demanding industrial environments. This module plays a pivotal role in integrating sensor data and control signals within gas, steam, and industrial turbine systems, ensuring reliable operation in power plants, petrochemical facilities, and metallurgical processes . Its robust design and flexible configuration make it a cornerstone of GE’s Speedtronic control architecture, which has been trusted for decades in mission-critical energy applications.

Technical Specifications — GE DS200TCQCG1AJD

| Parameter | Value |

| Product Model | GE DS200TCQCG1AJD |

| Series | Mark V by GE |

| Function Type | RST Overflow Board / Analog I/O Expander |

| Power Requirement | 24 VDC |

| Rated current | 4 A |

| Processor | Freescale 8349 (667 MHz) with 3 microprocessors |

| Control Accuracy | ±0.25% |

| Connectors | 24 configurable jumpers, 3×40-pin connectors, 3×34-pin connectors, 1×16-pin connector |

| Operating Temperature | -40°C to +85°C (inferred from similar Mark V modules) |

| Communication Protocols | IONet (primary), Modbus/Profibus compatible (inferred) |

| Mounting | DIN-rail or panel-mounted (compatible with Mark V cabinets) |

GE DS200TCQCG1AJD

Key Features and Applications

- Industrial-Grade Reliability: Built with conformal coating and wide temperature tolerance, making it suitable for dusty turbine rooms and harsh industrial environments. The robust design ensures stable operation even in vibration-prone settings .

- Mark V Ecosystem Integration: Seamlessly connects with R1/R2/R3 cores of Mark V systems, handling analog signal processing for sensors (LVDTs, pressure transducers) and servo outputs. Its plug-and-play compatibility reduces system downtime during upgrades .

- Advanced Signal Processing: Equipped with high-precision analog-to-digital conversion and configurable jumpers for customizing output current ranges, critical for precise turbine control and safety interlocks .

- Redundancy Support: Functions as an overflow board to manage excess I/O signals in redundant control architectures, enhancing system fault tolerance—a key requirement in power generation applications .

- Typical Applications:

- Gas/steam turbine control systems in power plants

- Industrial motor drive control (AC induction motors)

- Petrochemical process monitoring and actuation

- Metallurgical furnace temperature regulation

GE DS200TCQCG1AJD

Installation and Maintenance Guidelines

Mount the GE DS200TCQCG1AJD using standard DIN-rail clips or direct panel mounting in control cabinets. Ensure proper alignment with adjacent modules to maintain airflow—critical for heat dissipation in high-temperature environments. When replacing or upgrading, transfer PROM modules from the old board to preserve firmware configurations .

For maintenance:

- Inspect connector pins quarterly for corrosion, especially in humid environments.

- Verify jumper settings match system requirements after maintenance (refer to GE GEH-6226 manual for details) .

- Use compressed air to — remove dust from ventilation slots to prevent overheating.

GE DS200TCQCG1AJD

Related Models and Warranty

Related Mark V Modules:

- DS200TCQCG1AHE: Similar RST overflow board with alternate jumper configurations

- DS200TCQCG1BGF: Fiber-optic compatible variant with extended temperature range

- DS200TCCBG1ALD: Extended analog I/O card for Mark V legacy systems

The GE DS200TCQCG1AJD comes with a 1-year warranty from authorized suppliers, covering manufacturing defects but not physical damage from improper handling. For technical support or replacements, contact GE-certified distributors with the module’s serial number and application details .

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: