Description

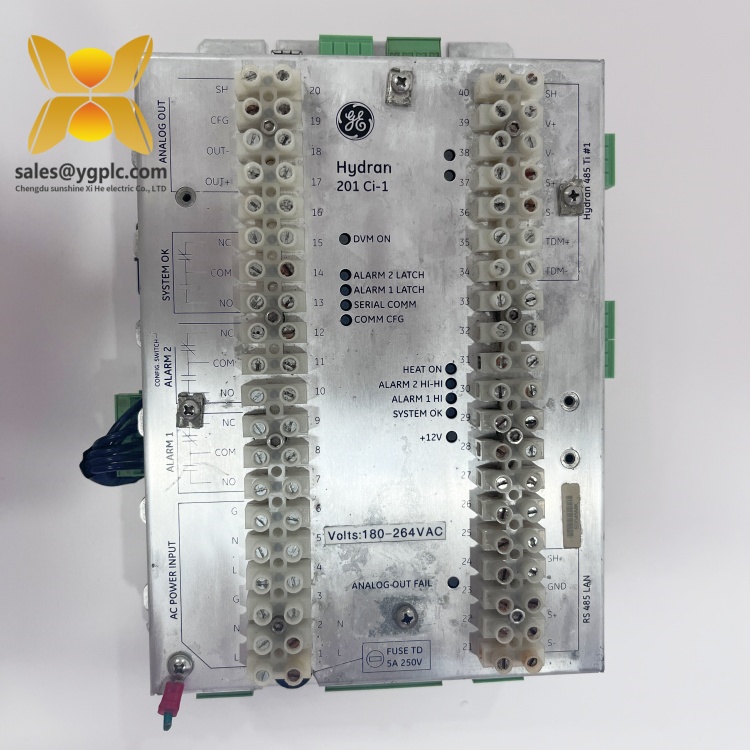

GE 201CI-1 VersaMax Digital Input Module

Product Overview:GE 201CI-1

The GE 201CI-1 is a high-performance Digital Input Module designed for industrial automation systems, serving as a critical interface between field devices and programmable logic controllers (PLCs). As part of GE’s VersaMax series—a versatile platform renowned for reliability in harsh industrial environments—the 201CI-1 enables seamless acquisition of discrete input signals from sensors, switches, and relays. This module supports 16 isolated channels, each capable of handling 24 V DC signals, making it ideal for applications requiring robust signal conditioning and noise immunity in manufacturing, energy, and process control sectors.

Engineered to enhance system responsiveness, the GE 201CI-1 features galvanic isolation (2.5 kV RMS) to protect against voltage surges and ground loops, ensuring accurate data transmission even in high-electromagnetic interference (EMI) environments. Its compact design (100 mm × 110 mm × 50 mm) and DIN rail mounting facilitate easy integration into control panels, while compatibility with GE’s VersaMax Micro and VersaMax I/O systems allows scalable expansion of input/output capabilities. By converting physical states (e.g., open/closed contacts) into digital signals for PLC processing, the 201CI-1 plays a pivotal role in real-time monitoring, safety interlocking, and process automation workflows.

In industrial ecosystems, the GE 201CI-1 bridges the gap between field instrumentation and higher-level control systems, enabling precise tracking of machine status, valve positions, and conveyor operations. Its diagnostic LEDs provide real-time feedback on signal integrity and module health, reducing troubleshooting time and minimizing unplanned downtime. Whether deployed in standalone machines or complex distributed control systems, this module delivers consistent performance, making it a trusted choice for industries prioritizing reliability and ease of integration.

Technical Specifications:GE 201CI-1

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 201CI-1 |

| Manufacturer | GE |

| Product Type | Digital Input Module |

| Input Channels | 16 isolated channels |

| Input Voltage | 24 V DC ±10% |

| Isolation | Galvanic isolation (2.5 kV RMS) |

| Physical Dimensions | 100 mm (H) × 110 mm (W) × 50 mm (D) |

| Weight | 0.4 kg |

| Power Supply | 24 V DC (shared with I/O rack) |

| Operating Temperature | -25°C to +70°C |

| Mounting | DIN rail (35 mm) |

| Communication | Proprietary via VersaMax backplane |

GE 201CI-1

Key Features and Advantages:GE 201CI-1

High-Reliability Isolation: Each channel of the GE 201CI-1 is galvanically isolated, preventing electrical noise from compromising signal quality. This feature is critical in environments with heavy machinery or power fluctuations, ensuring stable operation and reducing the risk of false readings.

Compact and Modular Design: With its sleek form factor, the 201CI-1 optimizes space in control panels, making it suitable for both new installations and retrofits. Its plug-and-play compatibility with other VersaMax modules (e.g., output modules, communication gateways) allows flexible system configuration without complex re-wiring.

Real-Time Diagnostics: Built-in LED indicators provide instant visual feedback on channel status (e.g., signal present, fault detected), enabling rapid identification of issues. This proactive diagnostic capability minimizes downtime and streamlines maintenance workflows.

Wide Environmental Tolerance: Designed to withstand extreme temperatures (-25°C to +70°C) and mechanical stress (vibration: 5 g, shock: 30 g), the 201CI-1 excels in harsh industrial settings, including factories, oil rigs, and outdoor installations.

Scalable Integration: As part of the VersaMax ecosystem, the module can be combined with GE’s VMX Series Controllers and VersaMax I/O Expansion Racks to create tailored automation solutions. This scalability allows users to start with small systems and expand as operational needs grow.

GE 201CI-1

Application Areas:GE 201CI-1

The GE 201CI-1 is widely applied in industries requiring precise monitoring of discrete signals:

- Manufacturing: Monitors limit switches, proximity sensors, and safety interlocks in assembly lines, robotic cells, and packaging machines to ensure process accuracy and operator safety.

- Energy Production: Tracks valve positions, pump status, and generator breaker states in power plants and renewable energy facilities, supporting seamless integration with SCADA systems.

- Water/Wastewater Treatment: Detects level switches, flow meters, and pump 启停 signals in treatment plants, enabling automated control of filtration, dosing, and distribution processes.

- Material Handling: Controls conveyor belt alignment, hoist positions, and palletizer operations in logistics and warehousing, optimizing throughput and reducing manual intervention.

Specific use cases include:

- Safety Systems: Integrates with emergency stop buttons and door interlocks to trigger immediate shutdowns in hazardous situations.

- Predictive Maintenance: Captures machine cycle counts and fault signals to schedule proactive maintenance, extending equipment lifespan.

- Process Automation: Converts binary inputs from pressure switches or temperature sensors into actionable data for PLC-based control logic.

Related Products

- GE 200CO-1 (Digital Output Module): Pairs with the 201CI-1 to form complete input/output control loops, enabling bidirectional communication with actuators and motors.

- GE 201AI-1 (Analog Input Module): Expands system capabilities by adding analog signal acquisition (e.g., 4–20 mA, voltage) for mixed-signal applications.

- GE VMX-1500 Controller: A high-performance PLC controller that interfaces with the 201CI-1 to execute complex control logic and data processing.

- GE 2085-PA2 Power Supply: Provides reliable 24 V DC power for VersaMax I/O racks, ensuring stable operation of the 201CI-1 and other modules.

- GE 2090-CBL008 Communication Cable: Facilitates high-speed data transfer between the 201CI-1 and remote I/O racks, supporting distributed control architectures.

- GE 201DI-1 (Dual Digital Input Module): Offers 32 channels in a single module for applications requiring higher input density, serving as a scalable alternative to the 201CI-1.

- GE 202OC-1 (Relay Output Module): Provides electromechanical relay outputs for switching high-power loads, complementing the 201CI-1 in motor control applications.

- GE VersaMax I/O Expansion Rack: Houses multiple modules (including the 201CI-1) and provides backplane connectivity, enabling flexible system expansion.

GE 201CI-1

Installation and Maintenance

Installation Preparation:

Before installing the GE 201CI-1, ensure the DIN rail is securely mounted and grounded. Verify that the power supply (24 V DC) matches the module’s requirements and that field devices are wired correctly (e.g., sinking/sourcing inputs). Mount the module on the rail, ensuring proper spacing for heat dissipation, and connect it to the VersaMax backplane using the provided connectors. Use GE’s Proficy Machine Edition software to configure input parameters (e.g., debounce time, filter settings) and map channels to the PLC program.

Before installing the GE 201CI-1, ensure the DIN rail is securely mounted and grounded. Verify that the power supply (24 V DC) matches the module’s requirements and that field devices are wired correctly (e.g., sinking/sourcing inputs). Mount the module on the rail, ensuring proper spacing for heat dissipation, and connect it to the VersaMax backplane using the provided connectors. Use GE’s Proficy Machine Edition software to configure input parameters (e.g., debounce time, filter settings) and map channels to the PLC program.

Maintenance Recommendations:

- Routine Checks: Inspect the module monthly for loose connections, corrosion, or overheating. Clean the enclosure with a dry cloth to prevent dust accumulation that could affect performance.

- Signal Integrity Testing: Periodically verify input signals using a multimeter to ensure voltage levels fall within the specified range (21.6–26.4 V DC). Document test results for compliance.

- Firmware Updates: Although the 201CI-1 has fixed firmware, regularly update the connected PLC controller’s firmware to ensure compatibility and access new features.

- Spare Parts Management: Store spare 201CI-1 modules in anti-static packaging at room temperature (10–30°C) with low humidity (<60%) to preserve component reliability.

GE 201CI-1

Product Warranty

Our company provides a 12-month quality warranty for the GE 201CI-1, covering hardware defects under normal use. In the event of unexpected failures, we offer prompt replacement services to minimize operational disruptions. For legacy or hard-to-find models like the 201CI-1, our global supply chain network specializes in sourcing rare industrial control parts, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering reliable solutions to keep your automation systems running smoothly.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IC698CRE030-DE Communication output interface component

GE IC698PSA350E Interface component

GE IC698PSD300C DCS card module

GE IC698RMX016-ED Data acquisition module

GE ACC-5595-208 350-805595-208N probe

GE IS420UCSBH4A Tachometer sensor

GE IS200TSVCH1AED Digital relay output module

GE IS200TRPGH1BDD S1C5029 Output module digit

GE IS200TSVCH1ADC S1CX01H PXI module

GE DS200DCFBG2BNC MRP445970 Switch input module

GE DS200DCFBG2BNC MRP420024 Control processor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: