Description

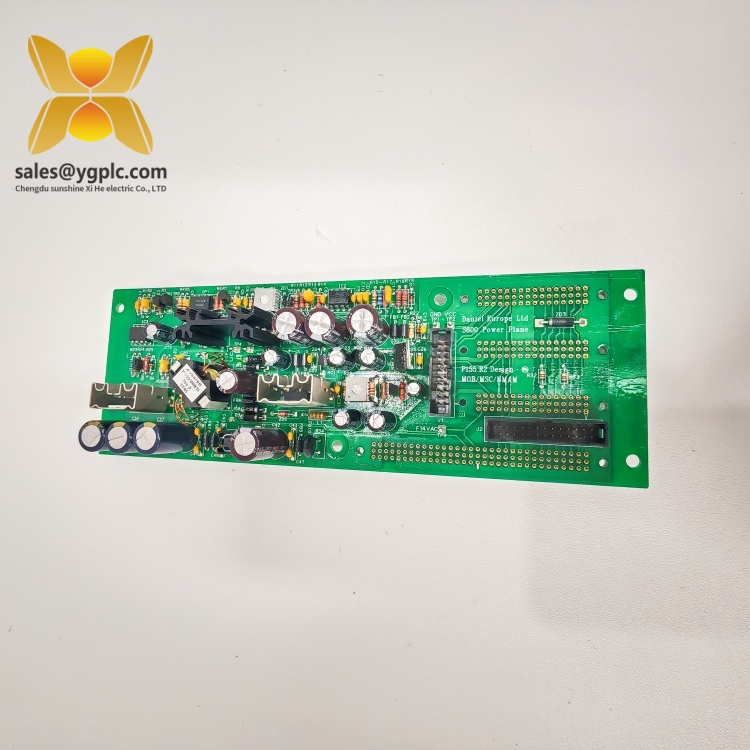

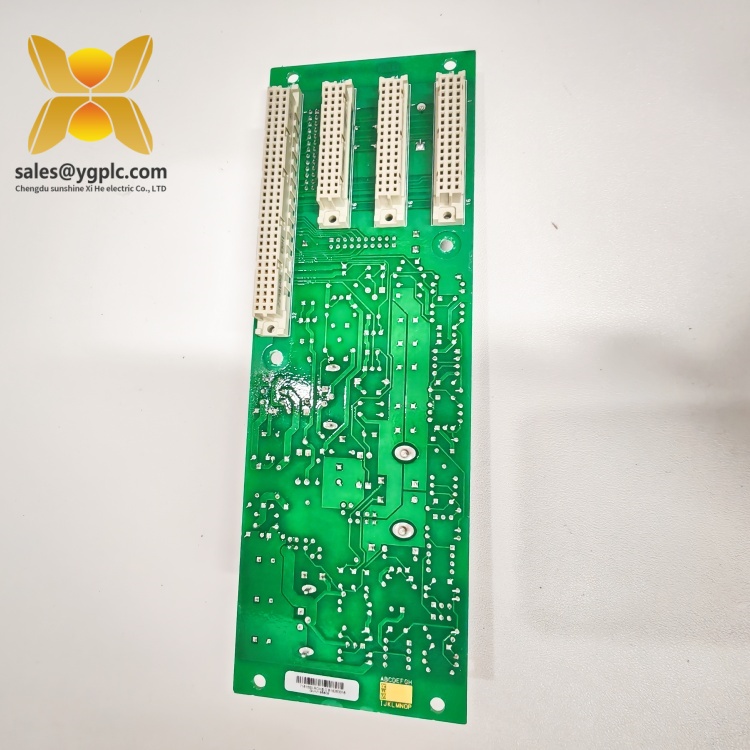

Emerson P155.R2 Vibration Monitoring Module

Product Overview:Emerson P155.R2

The Emerson P155.R2 vibration monitoring module is a high-precision industrial device designed for real-time condition monitoring of rotating machinery in critical applications. As part of Emerson’s CSI 6500 Machinery Health Monitoring System, this module delivers advanced vibration analysis and protection, ensuring optimal performance and reliability of turbines, compressors, and pumps in diverse industrial environments.

The P155.R2 supports multiple sensor inputs, including proximity probes and accelerometers, to measure key parameters such as radial vibration, axial displacement, and velocity. Its dual-channel design allows simultaneous monitoring of two independent signals, while user-programmable alarm setpoints and relay outputs enable precise control over machinery protection. Built with Emerson’s rugged industrial standards, the P155.R2 features a compact form factor and robust construction, making it suitable for harsh environments with high levels of noise, dust, or vibration.

In automation systems, the P155.R2 serves as a vital component of predictive maintenance strategies, providing actionable insights into machinery health to reduce unplanned downtime. Its compatibility with Emerson’s AMS Suite software enables seamless data integration and remote diagnostics, enhancing operational efficiency across industries. By combining high accuracy with reliable performance, the P155.R2 helps manufacturers maintain equipment longevity and comply with safety standards.

Technical Specifications:Emerson P155.R2

| Parameter Name | Parameter Value |

|---|---|

| Product Model | P155.R2 |

| Manufacturer | Emerson |

| Product Type | Vibration Monitoring Module |

| Input Channels | 2 (dual-channel) |

| Sensor Compatibility | Proximity probes, accelerometers |

| Frequency Range | 0.1 Hz to 10 kHz |

| Output Signals | 4–20 mA, 0–10 V DC, relay contacts |

| Power Supply | 24 V DC ±10% |

| Physical Dimensions | 178 mm (H) × 102 mm (W) × 254 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (19-inch standard) |

P155.R2

Key Features and Advantages:Emerson P155.R2

Dual-Channel Flexibility: The P155.R2’s dual-channel architecture allows simultaneous monitoring of two parameters, such as vibration and displacement, reducing the need for multiple modules and simplifying system design. Each channel can be independently configured for specific sensor types and measurement ranges.

High Precision and Reliability: With a ±1% measurement accuracy, the module ensures reliable data collection even in high-vibration environments. Its EMI/RFI protection and rugged enclosure (IP54-rated) safeguard against electrical interference and environmental hazards, ensuring consistent performance over extended periods.

Predictive Maintenance Integration: The module’s compatibility with Emerson’s AMS Machinery Manager software enables real-time trend analysis and fault detection, allowing operators to identify issues like bearing wear or shaft misalignment before they escalate. This proactive approach minimizes maintenance costs and improves system uptime.

Easy Integration and Configuration: The P155.R2 integrates seamlessly with Emerson’s CSI 6500 system, supporting plug-and-play functionality and intuitive configuration via the AMS Suite. Its standardized interfaces and modular design reduce installation time and enhance scalability for complex industrial setups.

Redundant Safety Features: Built-in relay outputs provide immediate alarm responses to critical events, while redundant power inputs ensure continuous operation during power fluctuations. These features make the P155.R2 suitable for safety-critical applications in oil & gas and power generation.

P155.R2

Application Areas:Emerson P155.R2

The Emerson P155.R2 vibration monitoring module is widely deployed across industries that rely on rotating machinery:

- Power Generation: Monitors steam turbines, gas generators, and pumps in thermal and nuclear power plants, ensuring stable energy production and compliance with environmental regulations. The module’s ability to track vibration trends helps prevent catastrophic failures in high-value assets.

- Oil & Gas: Used in refineries, offshore platforms, and pipeline systems to monitor compressors, motors, and centrifugal pumps. Its rugged design withstands harsh offshore conditions, including saltwater corrosion and extreme temperatures.

- Manufacturing: Integrates with production lines to monitor CNC machines, conveyors, and industrial fans. Real-time vibration data helps optimize machine performance and reduce downtime in automotive, pharmaceutical, and food processing facilities.

- Water Treatment: Tracks the health of pumps and blowers in wastewater treatment plants, ensuring continuous operation and regulatory compliance. The module’s reliability is critical for maintaining water quality and process efficiency.

- Aerospace and Defense: Supports vibration analysis in testing facilities for aircraft engines and military equipment, ensuring component durability and performance under extreme conditions.

Related Products:Emerson P155.R2

- Emerson P150.R1: A single-channel variant of the P155.R2, suitable for basic vibration monitoring applications where dual-channel functionality is not required.

- Emerson P160.R3: An upgraded model with advanced diagnostic features, including phase analysis and transient event recording, ideal for complex machinery setups.

- Emerson 2110 Accelerometer: A complementary sensor designed for high-frequency vibration measurement, compatible with the P155.R2 for enhanced data accuracy.

- Emerson 2475 Proximity Probe: Works with the P155.R2 to measure shaft displacement and vibration, offering high precision in harsh environments.

- Emerson AMS 6500 Rack: A modular rack system that houses the P155.R2 and other CSI 6500 modules, providing a centralized platform for machinery health monitoring.

- Emerson P156.R2: A dual-channel module with built-in temperature monitoring, expanding the P155.R2’s capabilities for multi-parameter analysis.

- Emerson P152.R2: A variant optimized for low-frequency applications, suitable for monitoring large-scale industrial turbines and generators.

P155.R2

Installation and Maintenance:Emerson P155.R2

Installation Preparation:

Before installing the P155.R2, ensure the CSI 6500 rack is properly grounded and powered. Verify sensor compatibility (e.g., 2475 proximity probes or 2110 accelerometers) and configure the module using Emerson’s AMS Suite software. Mount the module in the rack’s designated slot, secure all cable connections, and perform a system calibration to validate measurement accuracy.

Before installing the P155.R2, ensure the CSI 6500 rack is properly grounded and powered. Verify sensor compatibility (e.g., 2475 proximity probes or 2110 accelerometers) and configure the module using Emerson’s AMS Suite software. Mount the module in the rack’s designated slot, secure all cable connections, and perform a system calibration to validate measurement accuracy.

Maintenance Recommendations:

- Routine Inspections: Quarterly checks should include visual inspection of cable connections, sensor alignment, and module status indicators. Clean the module’s vents to prevent dust accumulation that could affect heat dissipation.

- Calibration: Recalibrate sensors and the P155.R2 annually using Emerson’s certified calibration tools to maintain measurement precision. Document calibration results for compliance and traceability.

- Firmware Updates: Periodically update the module’s firmware through the AMS Suite to access new features and security patches, ensuring compatibility with the latest software releases.

- Spare Parts Management: Maintain a spare P155.R2 module and compatible sensors in inventory to address unexpected failures promptly. Leverage Emerson’s global supply chain for quick replacement of discontinued components.

P155.R2

Product Guarantee:Emerson P155.R2

Our company offers a 12-month quality warranty for the Emerson P155.R2 vibration monitoring module, covering non-human-induced hardware defects. In the event of performance anomalies or functional failures during the warranty period, we provide prompt replacement services. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of scarce parts, minimizing downtime and supporting the continuous operation of industrial systems.

With 17 years of expertise in industrial control distribution, we pride ourselves on delivering reliable products, competitive pricing, and dedicated technical support. Contact us today to explore how the P155.R2 can enhance your machinery health monitoring strategy.

Note: All product names and trademarks belong to their respective owners. This document is for informational purposes and does not substitute official technical documentation. Always refer to Emerson’s manuals for detailed specifications and safety guidelines.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

EMERSON A6824 9199-00090 Output module

EMERSON A6410 9199-00005 Output module

EMERSON A6110 9199-00001 High density main box

EMERSON 5X00273G01 Remote extender module

EMERSON A6110 Input pulse module

EMERSON A6220 Digital output module

EMERSON A6210 Digital relay output module

EMERSON A6410 Output module digit

EMERSON A6740 PXI module

EMERSON KJ2221X1-BA1 Servo drive

EMERSON SLS1508 Servo motor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: