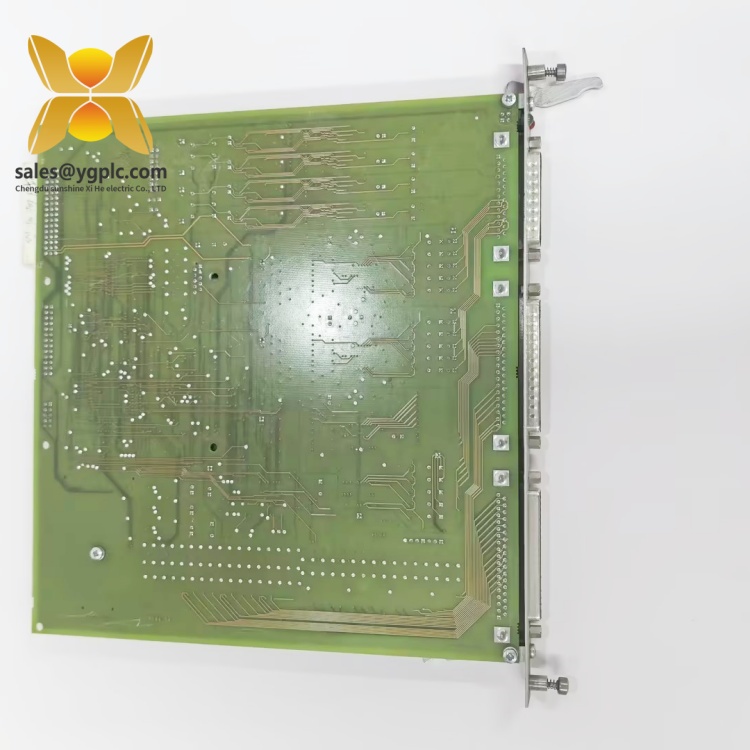

Description

EMERSON P144.R4 Pressure Transmitter Module

Product Overview : EMERSON P144.R4

The : EMERSON P144.R4 pressure transmitter module is a high-precision industrial instrument designed for critical pressure measurement and control in process automation systems. As part of Emerson’s DeltaV™ Series, this module combines advanced sensor technology with robust hardware to deliver reliable performance in harsh industrial environments. The P144.R4 is engineered to measure gauge, absolute, or differential pressure across a wide range of applications, making it an essential component for industries requiring precise process control, such as oil & gas, chemical processing, and power generation.

Featuring a 2-wire 4–20 mA output with HART® communication protocol, the P144.R4 enables seamless integration with distributed control systems (DCS) and programmable logic controllers (PLCs). Its digital signal processing (DSP) ensures high accuracy (±0.075% of span) and stability, while the hermetically sealed stainless steel housing provides protection against corrosion, vibration, and extreme temperatures (-40°C to 85°C). The module’s compact design (190 mm height, 1.3 kg weight) and DIN rail mounting facilitate easy installation in both new and retrofitted systems, reducing downtime and installation costs.

Within automation frameworks, the **EMERSON P144.R4 serves as a vital link between field sensors and control systems, converting pressure inputs into standardized electrical signals for real-time monitoring and control. Its intrinsic safety certification (ATEX/IECEx) makes it suitable for use in hazardous areas, ensuring compliance with international safety standards. By delivering reliable pressure data, the P144.R4 helps optimize process efficiency, prevent equipment failures, and enhance operational safety across diverse industrial applications.

Technical Specifications : EMERSON P144.R4

| Parameter Name | Parameter Value |

|---|---|

| Product Model | P144.R4 |

| Manufacturer | EMERSON |

| Product Type | Pressure Transmitter Module |

| Pressure Range | 0–10 bar (gauge) |

| Output Signal | 4–20 mA DC with HART® 7 protocol |

| Accuracy | ±0.075% of span |

| Power Supply | 10–30 V DC |

| Physical Dimensions | 190 mm (H) x 90 mm (W) x 60 mm (D) |

| Weight | 1.3 kg |

| Communication Protocol | HART® 7, optional FOUNDATION Fieldbus |

| Operating Temperature | -40°C to 85°C |

| Protection Rating | IP67, NEMA 4X |

| Country of Origin | United States |

EMERSON P144.R4

Main Features and Advantages : EMERSON P144.R4

High Precision and Stability: The P144.R4 utilizes advanced MEMS sensor technology to deliver consistent pressure measurements with minimal drift, even in high-temperature or high-vibration environments. Its auto-calibration feature reduces maintenance needs, ensuring long-term accuracy without frequent adjustments.

Robust Industrial Design: The module’s stainless steel wetted parts and hermetically sealed enclosure provide exceptional resistance to corrosion and harsh conditions, making it suitable for applications in offshore platforms, chemical plants, and other demanding environments. The IP67 rating ensures protection against dust and water immersion, enhancing reliability in outdoor or washdown areas.

Flexible Integration: With support for HART® and FOUNDATION Fieldbus protocols, the P144.R4 integrates seamlessly with Emerson’s DeltaV™ system and third-party control platforms. Its plug-and-play compatibility allows for quick configuration via handheld communicators or PC software, minimizing setup time and reducing the risk of human error.

Safety Compliance: The ATEX/IECEx certification ensures the module meets strict safety standards for use in explosive atmospheres (Zone 1/21). This makes it ideal for oil refineries, gas processing facilities, and other hazardous locations where equipment reliability and safety are non-negotiable.

Energy Efficiency: The low-power design (typically 0.5 W) reduces energy consumption, contributing to lower operational costs. The module’s diagnostic capabilities (e.g., sensor failure detection, process variable alerts) enable predictive maintenance, further optimizing system uptime and reducing unplanned downtime.

Application Areas : EMERSON P144.R4

The EMERSON P144.R4 pressure transmitter module is widely deployed across industries that require precise pressure monitoring and control:

- Oil & Gas: Used in upstream production (wellheads, separators), midstream transportation (pipelines, pump stations), and downstream refining. The P144.R4 monitors well pressure, pipeline integrity, and distillation column operations, ensuring safe and efficient production processes.

- Chemical Processing: Ideal for measuring pressure in reactors, storage tanks, and transfer systems. The module’s corrosion-resistant design makes it suitable for handling aggressive chemicals, while its safety certifications comply with strict industry regulations.

- Power Generation: Installed in steam turbines, boilers, and cooling systems to monitor pressure levels, ensuring optimal performance and preventing overpressure incidents. The P144.R4 supports both conventional and renewable energy applications, such as solar thermal plants and biomass facilities.

- Water/Wastewater Treatment: Measures pressure in pumps, valves, and filtration systems to maintain consistent water flow and quality. Its ability to withstand moisture and humidity makes it suitable for wastewater treatment plants and marine environments.

- Pharmaceuticals and Food & Beverage: Used in sterile processing environments to monitor pressure in fermentation tanks, autoclaves, and filling lines. The module’s hygienic design and ease of cleaning meet strict regulatory requirements for these industries.

EMERSON P144.R4

Related Products : EMERSON P144.R4

- EMERSON P320.R4: A differential pressure transmitter in the same series, designed for flow measurement and level monitoring in closed systems.

- EMERSON P450.R4: An absolute pressure transmitter with a wider pressure range (up to 100 bar), suitable for high-pressure applications like gas compression.

- EMERSON P144D.R4: A dual-range version of the P144.R4, allowing users to switch between two pressure ranges without recalibration.

- EMERSON X-STREAM XD200: A gas analyzer that integrates with the P144.R4 to provide comprehensive process monitoring in refineries and petrochemical plants.

- EMERSON DeltaV™ PM630: A process module that works alongside the P144.R4 to manage analog input signals within the DeltaV™ control system.

- EMERSON 2700T Temperature Transmitter: A complementary product for multi-parameter monitoring, combining temperature and pressure data for holistic process control.

- EMERSON ASCO 212 Series Valves: Actuation components that can be controlled using signals from the P144.R4 in automated process loops.

Installation and Maintenance : EMERSON P144.R4

Pre-installation Preparations:

Before installing the P144.R4, verify that the process media and environmental conditions (temperature, pressure) are within the module’s specified range. Ensure the power supply (10–30 V DC) is stable and properly grounded to avoid electromagnetic interference. Clean the mounting area and inspect the process connection for debris. Mount the module on a DIN rail or directly on a flat surface using the provided brackets, ensuring proper alignment with the pressure port. Connect the power and signal cables using the terminal block, following Emerson’s wiring diagrams to avoid polarity errors.

Before installing the P144.R4, verify that the process media and environmental conditions (temperature, pressure) are within the module’s specified range. Ensure the power supply (10–30 V DC) is stable and properly grounded to avoid electromagnetic interference. Clean the mounting area and inspect the process connection for debris. Mount the module on a DIN rail or directly on a flat surface using the provided brackets, ensuring proper alignment with the pressure port. Connect the power and signal cables using the terminal block, following Emerson’s wiring diagrams to avoid polarity errors.

Maintenance Recommendations:

- Routine Inspections: Perform monthly visual checks for signs of leaks, corrosion, or physical damage. Use a HART® communicator to review diagnostic messages and ensure the module is operating within specified parameters.

- Calibration: Calibrate the P144.R4 annually using Emerson’s AMS Device Manager software or a dedicated calibration tool. Compare readings against a known reference standard to maintain accuracy.

- Environmental Checks: In harsh environments, clean the module’s exterior quarterly to remove dust, moisture, or chemical deposits that could affect performance. Inspect cable connections for tightness and signs of wear.

- Firmware Updates: Periodically check Emerson’s website for firmware updates that may include new features, bug fixes, or compatibility improvements with control systems.

EMERSON P144.R4

Product Warranty : EMERSON P144.R4

Our company offers a 12-month quality warranty for the EMERSON P144.R4 pressure transmitter module, covering hardware defects and performance issues arising from non-human causes. If the module fails to meet specifications during the warranty period, we will replace it at no additional cost, ensuring minimal disruption to your operations. For discontinued models or urgent repair needs, our global supply chain network enables rapid fulfillment of spare parts, leveraging decades of expertise in industrial control distribution.

With 17 years of experience in supplying critical automation components, we are committed to delivering products that meet the highest standards of reliability and performance. The P144.R4 exemplifies our dedication to providing solutions that enhance operational efficiency and safety across industries. Contact us today to explore how this module can optimize your pressure measurement needs, supported by our responsive technical team and extensive inventory of industrial spares.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for official technical documentation. Always refer to Emerson’s manuals for detailed installation, operation, and safety guidelines.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: