Description

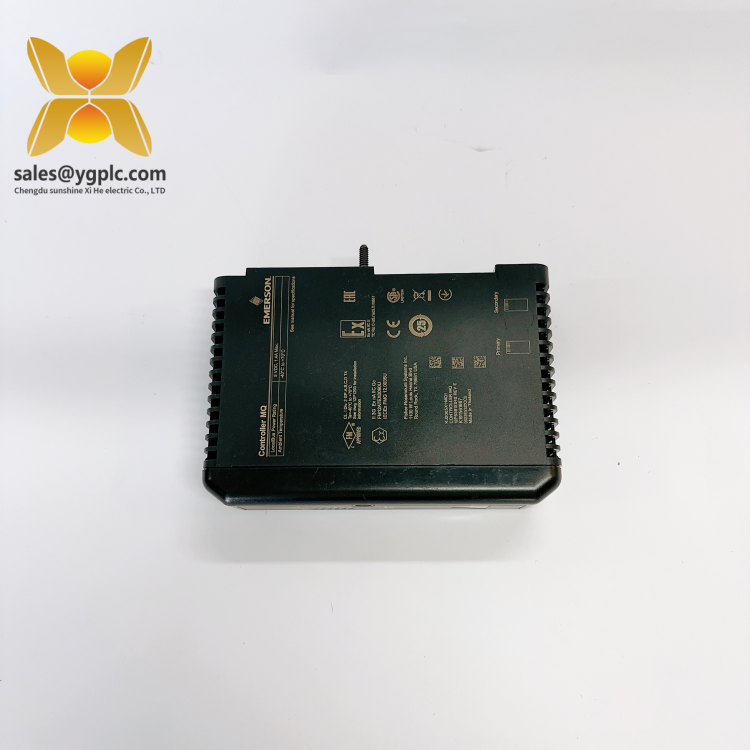

EMERSON KL3322X1-BA1 – Compact 2‑Channel Analog Voltage Input for Distributed I/O

The EMERSON KL3322X1-BA1 is a slice I/O analog input terminal designed to bring clean, stable voltage measurements into your PLC or controller with minimal wiring and cabinet space. It’s typically used for ±10 V or 0…10 V sensor signals where you need two reliable channels in a narrow DIN-rail form factor. From my experience, the “X1‑BA1” build code usually indicates an enhanced environmental option (often conformal coating), making it a safer pick for cabinets that see higher humidity or occasional dust.

You might notice that it slots into a modular backplane with a fieldbus or industrial Ethernet coupler up front, so it’s straightforward to standardize across machines—just add the channels you need. Typical applications include packaging skids, indexing stations, light process analogs, and test rigs that live and breathe ±10 V signals.

Key Features

- Two analog voltage inputs – Ideal for ±10 V or 0…10 V transducers; helps consolidate low-channel-count tasks neatly.

- Compact slice format – Narrow DIN-rail width typically near 12 mm; easy to expand or swap without reworking the whole panel.

- Stable, low-noise acquisition – Input filtering and high input impedance help maintain signal integrity in real cabinets.

- Status and diagnostics – Channel/status LEDs and limit reporting simplify troubleshooting during commissioning.

- Backplane/local bus interface – Works behind a compatible coupler so you can integrate with PROFINET, EtherNet/IP, or EtherCAT, depending on your head module.

- X1‑BA1 environmental build – In many cases this denotes conformal coating or similar protection for tougher shop-floor conditions.

- Field-friendly wiring – Spring-clamp style terminals (typical for this format) for quick install and reliable retention under vibration.

Technical Specifications

| Brand / Model | EMERSON KL3322X1-BA1 |

| Function | 2‑channel analog voltage input slice module |

| Input Range (typical) | ±10 V or 0…10 V (per channel; software selectable in most setups) |

| Resolution (typical) | 12‑bit class for KL33xx family modules |

| Isolation | Galvanic isolation between field I/O and backplane (typical for this series) |

| Power Requirements | 24 VDC field supply; 5 V from local bus (draw provided by coupler) |

| Operating Temperature | 0…+55 °C (standard cabinet environments) |

| Dimensions & Weight | Slim slice format; typical width ≈ 12 mm (lightweight) |

| Communication Interfaces | Via backplane/coupler; supports common fieldbuses/Ethernet (depending on the chosen coupler) |

| Installation Method | 35 mm DIN-rail; spring-clamp field terminals |

EMERSON KL3322X1-BA1

Application Fields

– Packaging and assembly lines: capture ±10 V feedback from position sensors, potentiometers, or amplifiers.

– Lab/test benches: simple two-channel analog capture without a full-size rack I/O footprint.

– Skid OEMs: distributed I/O in compact panels where cabinet space is tight and wiring needs to be fast.

– Utilities and infrastructure: light analog monitoring (valve positioners with voltage feedback, drives’ analog outputs).

– Educational/training rigs: budget-friendly way to teach or validate analog loops with real hardware.

One thing I appreciate is that, in most cases, you can keep the same head coupler and mix this module with digital I/O slices—handy when you only need two voltage channels on a machine that’s otherwise discrete.

Advantages & Value

- Space efficiency – Add just two channels without moving to a larger chassis or consuming extra panel depth.

- Flexible integration – Works with your existing coupler choice (PROFINET, EtherNet/IP, EtherCAT), reducing engineering time.

- Reliable measurement – Good noise immunity for a slice device; from my experience, readings are stable even near VFDs if wiring is done right.

- Lifecycle-friendly – Field-replaceable in minutes; minimizes downtime and spares overhead.

- Ruggedized variant – X1‑BA1 seems to be favored where coating or extra environmental resilience is desired.

EMERSON KL3322X1-BA1

A packaging customer told us they swapped this into an existing modular rack and were trending motor amplifier outputs within an hour—no rework on the coupler or PLC tags, just a quick channel scaling check.

Installation & Maintenance

- Cabinet & mounting – Standard 35 mm DIN-rail inside a ventilated enclosure; keep ambient under 55 °C for best longevity.

- Power & wiring – 24 VDC field supply; use shielded pairs for analog inputs, route away from high-frequency drives, and bond shields at one end to avoid ground loops.

- Grounding – Provide a clean reference; poor panel grounding is the most common source of drift and noise on ±10 V signals.

- Commissioning – Set input range and scaling in the PLC/engineering tool; verify zero/span with a stable source (a small calibrator is perfect).

- Maintenance – Re-torque/snap-check terminals during scheduled shutdowns; light dust cleaning only. Firmware and GSD/EDS/ESI files are managed at the coupler or controller level when applicable.

EMERSON KL3322X1-BA1

Quality & Certifications

- CE compliant; RoHS directive alignment for hazardous substances (typical for this class).

- UL Recognized component (many variants in this family carry UL marks; check your exact label for the X1‑BA1 build).

- Manufacturing under ISO 9001 quality systems.

- Standard manufacturer’s warranty: 12 months against defects (typical policy for industrial I/O modules).

Note: Specifications above reflect the common capabilities of the KL33xx 2‑channel voltage input format. If you’re matching an installed base, share your coupler type and firmware, and we’ll confirm the exact range/resolution set and environmental rating for the KL3322X1‑BA1 you’re procuring.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: