Description

EMERSON A6824 9199-00090 Vibration Monitoring Transmitter

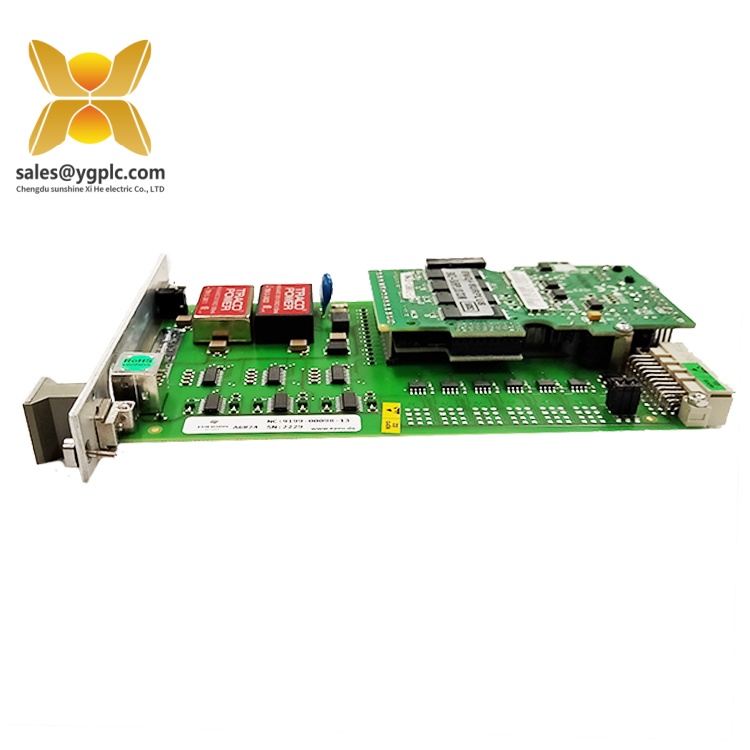

Product Overview:EMERSON A6824 9199-00090

The EMERSON A6824 9199-00090 vibration monitoring transmitter is a high-precision industrial device designed to provide real-time vibration analysis for rotating machinery in critical applications. As part of EMERSON’s A6800 Series of condition monitoring solutions, this transmitter combines advanced sensor technology with rugged construction to deliver reliable data for predictive maintenance and process optimization.

Engineered to detect and analyze vibration patterns in machinery such as turbines, compressors, and pumps, the A6824 9199-00090 converts raw vibration signals into standardized 4–20 mA analog outputs and digital data streams, enabling seamless integration with PLCs, DCS systems, and SCADA networks. Its dual-channel design supports simultaneous monitoring of both velocity and acceleration parameters, providing comprehensive insights into machinery health. The transmitter’s compact form factor (100mm x 75mm x 50mm) and DIN rail mounting capability make it suitable for space-constrained control cabinets, while its -40°C to +85°C operating temperature range ensures resilience in harsh industrial environments.

In automation systems, the A6824 9199-00090 serves as a critical component of proactive maintenance strategies, helping reduce unplanned downtime and extend equipment lifespan. By continuously monitoring vibration levels and transmitting real-time data to centralized control systems, it empowers operators to identify early signs of mechanical degradation, such as bearing wear or misalignment, and take corrective actions before failures occur. This transmitter is widely recognized for its accuracy, reliability, and ease of integration, making it an essential asset in industries where machinery uptime is non-negotiable.

Technical Specifications:EMERSON A6824 9199-00090

| Parameter Name | Parameter Value |

|---|---|

| Product Model | A6824 9199-00090 |

| Manufacturer | EMERSON |

| Product Type | Vibration Monitoring Transmitter |

| Input Signal | Accelerometer (IEPE) or velocity sensor |

| Output Signal | 4–20 mA (dual channels), Modbus RTU |

| Power Supply | 24V DC ±10% |

| Physical Dimensions | 100mm x 75mm x 50mm |

| Weight | 0.6 kg |

| Communication Protocol | Modbus RTU |

| Mounting Type | DIN rail or surface mount |

| Operating Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, ATEX (hazardous area compliant) |

A6824 9199-00090

Key Features and Advantages:EMERSON A6824 9199-00090

Dual-Parameter Monitoring: The A6824 9199-00090 supports simultaneous measurement of both vibration velocity (mm/s) and acceleration (g), providing a comprehensive view of machinery dynamics. This dual capability eliminates the need for separate sensors, simplifying system design and reducing installation costs.

High Accuracy and Stability: Built with advanced digital signal processing (DSP) technology, the transmitter delivers ±1% measurement accuracy across its full frequency range (10 Hz to 10 kHz). Its rugged aluminum enclosure and shock-resistant design ensure stable performance in high-vibration environments, such as industrial processing plants and offshore platforms.

Flexible Communication Options: With both analog (4–20 mA) and digital (Modbus RTU) outputs, the A6824 9199-00090 integrates seamlessly with legacy and modern control systems. This flexibility allows it to support a wide range of applications, from standalone machinery monitoring to large-scale distributed automation networks.

User-Friendly Configuration: The transmitter features a built-in LCD display and push-button interface for on-site configuration, enabling operators to set alarm thresholds, adjust filter settings, and view real-time vibration trends without additional software. For remote management, it can be configured via Modbus using standard HMI tools.

Hazardous Area Compliance: Certified for use in ATEX Zone 2 (gas) and Zone 22 (dust) environments, the A6824 9199-00090 is suitable for oil refineries, chemical plants, and other hazardous locations, ensuring compliance with strict safety standards.

A6824 9199-00090

Application Areas:EMERSON A6824 9199-00090

The EMERSON A6824 9199-00090 vibration monitoring transmitter is ideally suited for industries where precise machinery health monitoring is critical:

- Power Generation: Used to monitor steam turbines, gas generators, and pumps in thermal and renewable energy plants. By detecting abnormal vibration patterns, it helps prevent catastrophic failures and maintain consistent power output.

- Oil & Gas: Deployed in offshore platforms, refineries, and pipeline compressor stations to monitor the condition of rotating equipment. Its ATEX certification makes it suitable for use in explosive atmospheres, ensuring safety and operational continuity.

- Manufacturing: Integrates with production lines to monitor CNC machines, conveyor belts, and industrial fans. Real-time vibration data helps optimize maintenance schedules, reduce downtime, and improve overall equipment effectiveness (OEE).

- Water Treatment: Monitors pumps and blowers in wastewater treatment plants, ensuring reliable operation and compliance with environmental regulations. Early detection of mechanical issues helps avoid process interruptions and costly repairs.

- Aerospace and Defense: Used in testing facilities to monitor the vibration performance of aircraft engines and military equipment, ensuring reliability and safety in high-stakes applications.

Related Products:EMERSON A6824 9199-00090

- EMERSON A6820 9199-00080: A single-channel variant of the A6824 9199-00090, suitable for basic vibration monitoring applications where dual-channel capability is not required.

- EMERSON A6830 9199-00100: A high-temperature version designed for use in extreme environments (up to +125°C), ideal for monitoring kilns, furnaces, and other high-heat machinery.

- EMERSON A6850 9199-00120: A wireless vibration transmitter that complements the A6824 9199-00090 in remote or hard-to-reach locations, offering real-time data via Wi-Fi or Bluetooth.

- EMERSON A6810 9199-00070: A compact vibration sensor designed for direct mounting on machinery, providing raw vibration signals for use with the A6824 9199-00090 or other transmitters.

- EMERSON A6840 9199-00110: A multi-channel vibration monitoring system that can interface with multiple A6824 9199-00090 transmitters, offering centralized data management and analysis.

- EMERSON A6860 9199-00130: A explosion-proof enclosure kit for the A6824 9199-00090, enhancing its suitability for Zone 1/21 hazardous areas.

- EMERSON A6870 9199-00140: A calibration tool for the A6824 9199-00090, ensuring measurement accuracy and compliance with industry standards.

A6824 9199-00090

Installation and Maintenance:EMERSON A6824 9199-00090

Installation Preparation:

Before installing the A6824 9199-00090, ensure the mounting location is clean, dry, and within the specified temperature range. Verify that the power supply (24V DC) and wiring comply with EMERSON’s specifications. For DIN rail mounting, secure the transmitter to the rail using the provided clips. For surface mounting, use the included screws and ensure proper grounding to minimize electromagnetic interference. Connect the sensor cables to the transmitter’s input terminals, ensuring polarity is correct, and terminate the output signals to the control system using shielded twisted-pair cables.

Before installing the A6824 9199-00090, ensure the mounting location is clean, dry, and within the specified temperature range. Verify that the power supply (24V DC) and wiring comply with EMERSON’s specifications. For DIN rail mounting, secure the transmitter to the rail using the provided clips. For surface mounting, use the included screws and ensure proper grounding to minimize electromagnetic interference. Connect the sensor cables to the transmitter’s input terminals, ensuring polarity is correct, and terminate the output signals to the control system using shielded twisted-pair cables.

Maintenance Recommendations:

- Routine Inspections: Conduct monthly visual inspections to check for loose connections, damaged cables, or signs of overheating. Clean the transmitter’s enclosure with a dry cloth to prevent dust accumulation, which can affect heat dissipation.

- Calibration: Perform annual calibration using the EMERSON A6870 9199-00140 calibration tool to ensure measurement accuracy. Compare the transmitter’s output against a known reference vibration source and adjust as necessary.

- Firmware Updates: Periodically check EMERSON’s official website for firmware updates that may include new features or bug fixes. Use the provided software to update the transmitter’s firmware, following the manufacturer’s guidelines to avoid corruption.

- Spare Parts Management: Maintain a spare A6824 9199-00090 in inventory to minimize downtime in case of failure. Ensure spare units are stored in a controlled environment to preserve their operational integrity.

A6824 9199-00090

Product Warranty:EMERSON A6824 9199-00090

We provide a 12-month quality warranty for the EMERSON A6824 9199-00090 vibration monitoring transmitter, covering hardware defects caused by non-human factors. During the warranty period, we will replace any malfunctioning unit free of charge. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of scarce spare parts, supporting continuous operation of industrial systems.

With 17 years of expertise in industrial control parts distribution, we guarantee competitive pricing, fast delivery, and reliable technical support. Contact us today to enhance your machinery health monitoring capabilities with the A6824 9199-00090 vibration monitoring transmitter.

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not constitute an official technical manual. Always refer to the manufacturer’s documentation for detailed specifications and installation guidelines.

ABB GDD471A001 AI/AO/DI/DO module

ABB 1TGB302003R0003 Program module

ABB SPAJ110C Ethernet

ABB UFC721BE101 Integrated protection device

ABB UAD149A0011 Servo valve

ABB REF542PLUS Gas turbine card

PACIFIC 33VM52-000-29 PDP panel

Woodward 8237-1369 Remote module

Woodward 8237-1600 Main processor

ALSTOM CMP1838 TRVCO62345000 CP00005202 Pulse input

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: