Description

EMERSON A6110 9199-00001 Product Specification

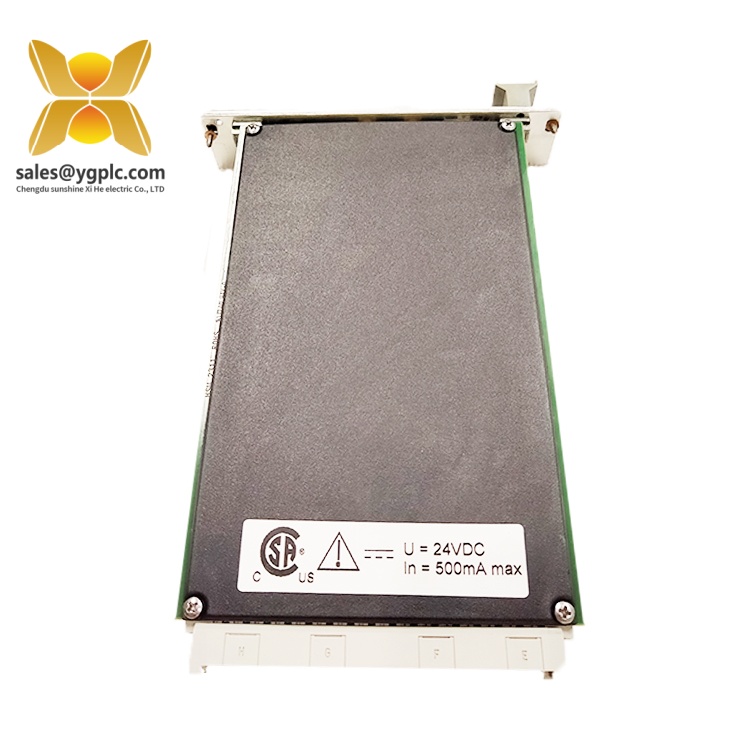

Product Overview:EMERSON A6110 9199-00001

The EMERSON A6110 9199-00001 is a high-precision shaft relative vibration monitor engineered for mission-critical rotating machinery in industrial environments. As part of Emerson’s AMS 6500 Mechanical Health Monitoring System, this module delivers real-time vibration analysis to ensure the reliability and efficiency of turbines, compressors, and pumps. Designed to meet API 670 standards, the EMERSON A6110 9199-00001 combines advanced sensor technology with robust diagnostics to detect early signs of equipment degradation, minimizing unplanned downtime and extending asset lifespan.

At its core, the EMERSON A6110 9199-00001 features dual independent measurement channels that monitor axial, radial, or tangential vibrations with exceptional accuracy. Each channel supports eddy current displacement sensors (e.g., Emerson models 6422, 6423), enabling precise detection of shaft movement relative to the stationary housing. The module’s wide frequency range (0.1–1000 Hz) and high resolution (0.001 mm/s) ensure reliable performance across diverse applications, from slow-speed turbines to high-speed compressors. With a compact 3U form factor and hot-swappable design, the EMERSON A6110 9199-00001 optimizes cabinet space while facilitating seamless integration into existing AMS 6500 systems.

In automation systems, the EMERSON A6110 9199-00001 acts as a vital component of predictive maintenance strategies. It continuously compares vibration data against predefined alarm setpoints, triggering relays and annunciations to alert operators of potential failures. By integrating with Emerson’s Plantweb™ digital ecosystem, the module enables remote monitoring and diagnostics via AMS Device Manager, empowering maintenance teams to make data-driven decisions. Whether installed in oil refineries, power plants, or pulp mills, the EMERSON A6110 9199-00001 ensures machinery operates within safe parameters, reducing repair costs and enhancing operational efficiency.

Technical Specifications:EMERSON A6110 9199-00001

| Parameter Name | Parameter Value |

|---|---|

| Product Model | EMERSON A6110 9199-00001 |

| Manufacturer | Emerson |

| Product Type | Shaft Relative Vibration Monitor |

| Measurement Channels | Dual independent channels |

| Sensor Compatibility | Eddy current displacement sensors (e.g., Emerson 6422, 6423) |

| Frequency Range | 0.1–1000 Hz |

| Accuracy | ±0.5% of reading |

| Resolution | 0.001 mm/s |

| Physical Dimensions | 16 cm (W) × 16 cm (H) × 12 cm (D) |

| Weight | 0.8 kg |

| Power Supply | 24 VDC ±10% |

| Communication Interfaces | RS-232, RS-485 |

| Alarm Outputs | 2 dry contact relays |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, API 670 |

A6110 9199-00001

Main Features and Advantages:EMERSON A6110 9199-00001

Dual-Channel Measurement: The EMERSON A6110 9199-00001’s dual-channel design allows simultaneous monitoring of two vibration parameters (e.g., horizontal and vertical shaft movement), providing a comprehensive view of machinery health. This redundancy enhances fault detection accuracy and reduces false alarms.

High-Speed Data Processing: With a response time of 1 millisecond, the module delivers real-time vibration data to the control system, enabling rapid adjustments to operational parameters. This speed is critical for preventing catastrophic failures in high-speed rotating equipment.

API 670 Compliance: Built to meet the rigorous standards of API 670, the EMERSON A6110 9199-00001 ensures compliance with industry regulations for machinery protection systems. Its fail-safe design and self-diagnostic capabilities (e.g., sensor cable integrity checks) further enhance safety and reliability.

Flexible Configuration: Users can customize measurement ranges (0–50 mils/1.27 mm), filter settings, and alarm thresholds via Emerson’s AMS software. This adaptability makes the module suitable for diverse applications, from monitoring steam turbines to large industrial pumps.

Robust Construction: The module’s rugged enclosure and wide temperature range (-25°C to +60°C) ensure reliable performance in harsh environments, including offshore platforms and high-dust manufacturing facilities. Its hot-swappable design minimizes downtime during maintenance.

A6110 9199-00001

Application Areas:EMERSON A6110 9199-00001

The EMERSON A6110 9199-00001 is widely deployed in industries where machinery reliability is paramount:

-

Power Generation:

- Monitors steam and gas turbines to detect imbalance, misalignment, or bearing wear, ensuring stable energy production and grid stability.

- Integrates with Emerson’s Ovation™ control system to optimize turbine efficiency and reduce emissions.

-

Oil and Gas:

- Protects compressors and pumps in upstream and downstream processes by detecting excessive vibration caused by cavitation or mechanical wear.

- Supports predictive maintenance programs in offshore platforms, minimizing the need for costly shutdowns.

-

Pulp and Paper:

- Monitors large rotating machines like refiners and paper machines to prevent vibration-induced quality defects and production delays.

- Enables condition-based maintenance, extending equipment lifespan and reducing replacement costs.

-

Mining and Cement:

- Ensures reliable operation of crushers, mills, and conveyor systems by providing early warnings of component fatigue or misalignment.

- Integrates with plant-wide SCADA systems for centralized monitoring and control.

A6110 9199-00001

Related Products:EMERSON A6110 9199-00001

- EMERSON 6422 Eddy Current Sensor: A compatible displacement sensor designed for high-precision shaft vibration measurement, often paired with the EMERSON A6110 9199-00001 for comprehensive monitoring.

- EMERSON A6120 9199-00002: A dual-channel axial position monitor that complements the A6110 in multi-parameter machinery protection systems.

- EMERSON A6130 9199-00003: A casing expansion monitor for detecting thermal growth in turbines, enhancing the A6110’s ability to assess overall machinery health.

- EMERSON A6140 9199-00004: A differential pressure monitor used alongside the A6110 to analyze bearing performance in high-pressure applications.

- EMERSON AMS 6500 System: The broader platform that includes the A6110, offering advanced analytics and remote diagnostics for integrated machinery health management.

Installation and Maintenance:EMERSON A6110 9199-00001

Pre-Installation Preparation:

Before installing the EMERSON A6110 9199-00001, ensure the following:

Before installing the EMERSON A6110 9199-00001, ensure the following:

- Verify the power supply meets the module’s requirements (24 VDC ±10%) and that the AMS 6500 rack is properly grounded.

- Install the module in a 3U slot of the AMS 6500 chassis, using the TP867 baseplate for secure mechanical and electrical connections.

- Calibrate the eddy current sensors (e.g., EMERSON 6422) using Emerson’s AMS Device Manager to ensure accurate vibration measurements.

Maintenance Recommendations:

- Regularly inspect the module’s LED indicators to confirm proper power and communication status. Flashing red LEDs may indicate sensor faults or communication errors.

- Clean the module’s vents and connectors quarterly to prevent dust accumulation, which can affect thermal performance.

- Update the module’s firmware annually using Emerson’s official software to access the latest features and bug fixes.

- Perform periodic sensor alignment checks to ensure the EMERSON 6422 sensors maintain optimal positioning relative to the monitored shaft.

A6110 9199-00001

Product Warranty:EMERSON A6110 9199-00001

Our company provides a one-year quality warranty for the EMERSON A6110 9199-00001, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models or urgent needs, our global supply chain network ensures rapid response to scarce spare parts requests, supporting the continuous and stable operation of industrial systems.

Note: This product description is based on publicly available technical data and industry applications. For detailed specifications, consult the official Emerson datasheet or contact our technical support team.

GE CK11CE300 High density main box

GE IS200TSVCH1AED Digital relay output module

GE IS200TRPGH1BDD S1C5029 Output module digit

GE DS200DCFBG2BNC MRP433745 Digital output module

GE DS200DCFBG2BNC MRP420024 Control system power supply

TRICONEX AI3351 Communication input interface component

TRICONEX MP3101 Communication output interface component

TRICONEX RO3451 Interface component

FOXBORO FBM202 P0926EQ PDP panel

FOXBORO P0926GV FBM231 programmable

FOXBORO P0926GU FBM230 Logic controller

FOXBORO FBM232 P0926GW Control panel

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: