Description

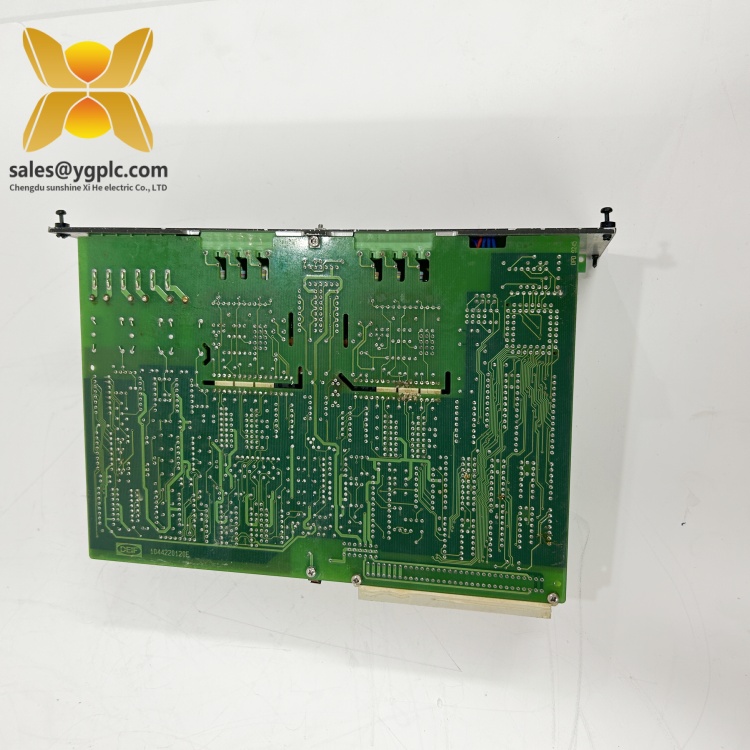

Product Overview

The DEIF SCM-1 Synchronizing/Measuring Module is a sophisticated and versatile device engineered to play a pivotal role in power management and control systems. As an integral part of DEIF’s comprehensive range of industrial solutions, the SCM-1 is designed to offer precise synchronization and accurate measurement capabilities, making it an essential component in various power – related applications.

Functionally, the SCM-1 serves as a multi – purpose module that combines the functions of a synchronizer, a generator breaker control unit, and a multi – transducer unit. It is capable of controlling a single generator set with respect to critical parameters such as frequency/active power control (which is related to speed control), breaker on/off control, and voltage/reactive power control. For instance, in a power generation setup, the SCM-1 ensures that the generator’s frequency and voltage are precisely adjusted to match the grid requirements during synchronization. This not only enables efficient power transfer but also helps in maintaining the stability of the overall power system.

In the context of an industrial automation system, the SCM-1 acts as a key enabler for seamless power distribution and equipment operation. By accurately measuring parameters like voltage, current, frequency, and power factor, it provides real – time data that is crucial for monitoring the health and performance of the power system. This data – driven approach allows for proactive maintenance and optimization, reducing the risk of unexpected downtime and enhancing the overall productivity of the industrial process.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SCM-1 |

| Manufacturer | DEIF |

| Product Type | Synchronizing/Measuring Module |

| Input Voltage Range | 8 – 35 VDC |

| Operating Temperature | – 25 °C to + 70 °C |

| Communication Interfaces | RS 485, Modbus |

| Synchronization Accuracy | ± 1 ms |

| Measurement Accuracy | ± 0.5% for voltage, current, power, frequency |

| Input Channels | Multiple for voltage, current, etc. |

| Output Channels | For control signals related to speed and voltage regulators |

| Weight | [Specify if available] |

| Physical Dimensions | [Specify if available] |

SCM-1

Key Features and Advantages

Precise Synchronization

The SCM-1 performs synchronization as a dynamic process. It takes into account factors such as ∆ frequency, ∆ voltage, and ∆ angle. For ∆ frequency, synchronization is carried out over – synchronous with respect to a programmable nominal frequency. This ensures that when the generator is connected to the busbar, the engine can immediately take on the load. Regarding ∆ voltage, the connection to the busbar occurs only when the difference between the busbar voltage and the generator voltage is less than a programmable ∆ voltage value. Similarly, for ∆ angle, the connection is made only when there is a coherent phase angle between the busbar voltage and the generator voltage, considering the generator breaker closing time (which is also programmable). This high – precision synchronization is vital for maintaining power quality and preventing electrical disturbances in power systems.

Comprehensive Parameter Measurement

It has the ability to measure a wide range of electrical parameters. Voltage, current, frequency, and power factor can all be accurately gauged. This comprehensive measurement capability allows operators to have a complete picture of the power system’s performance. For example, in an industrial plant, by continuously monitoring these parameters, potential issues such as over – voltage, under – current, or abnormal frequency fluctuations can be detected early, enabling timely corrective actions.

Communication Capabilities

Equipped with RS 485 and Modbus communication interfaces, the SCM-1 can easily communicate with other devices in the control system. This enables seamless integration into existing power management systems. Data collected by the module can be transmitted to a central monitoring station or other control devices. As a result, operators can remotely monitor and control the power generation and distribution processes, enhancing the overall efficiency and flexibility of the power system operation.

SCM-1

Reliable Design

Built to withstand harsh industrial environments, the SCM-1 has a robust construction. With an operating temperature range from – 25 °C to + 70 °C, it can function reliably in extreme conditions. Whether it is deployed in a cold outdoor power substation or a hot and humid industrial facility, the module’s performance remains stable, ensuring continuous and reliable operation of the power – related equipment it controls.

Application Areas

Power Generation

In power plants, the SCM-1 is used to synchronize generators with the grid. It ensures that the generated power meets the grid’s electrical requirements in terms of frequency, voltage, and phase angle. This is crucial for both traditional power plants, such as coal – fired or gas – powered plants, and renewable energy power plants like wind farms or solar power stations. In wind farms, for example, the SCM-1 helps in coordinating the operation of multiple wind turbines, ensuring that the power they generate can be smoothly integrated into the grid.

Industrial Automation

Industrial facilities rely on a stable power supply for their production processes. The SCM-1 is used to monitor and control the power distribution within the plant. It can measure the power consumption of different equipment, detect any power – related anomalies, and adjust the power supply accordingly. In a manufacturing plant with numerous motors, pumps, and other electrical equipment, the SCM-1 can help in optimizing the power usage, reducing energy waste, and preventing equipment failures due to power – related issues.

Emergency and Standby Power Systems

For emergency power systems in hospitals, data centers, and other critical facilities, the SCM-1 plays a vital role. When the main power supply fails, these standby generators need to be quickly synchronized and connected to the load. The SCM-1 ensures that this process occurs smoothly and accurately, providing a reliable backup power source. In a hospital, for instance, a seamless transition to standby power is essential to keep life – support systems and other critical medical equipment running without interruption.

SCM-1

Related Products

- DEIF DPD 02027: This may be a sets component that could be used in combination with the SCM-1 to enhance certain functions, perhaps related to data processing or additional control capabilities within the power management system.

- DEIF IOM 41: An input/output module that can work in tandem with the SCM-1. It may expand the number of input and output channels available, allowing for more complex control and monitoring setups in power systems.

- DEIF SCM 41: A related module within the SCM series. It might have similar synchronization and measurement functions as the SCM-1 but could be optimized for different power levels or application requirements, offering users more choices depending on their specific needs.

- DEIF RMF – 112 D: Possibly a relay or monitoring module that can be integrated with the SCM-1 to provide additional protection or enhanced monitoring features for the power system, such as over – current or over – voltage protection.

- DEIF DU – 2/Mkii: This could be a communication or interface unit that helps in better connectivity and data transfer between the SCM-1 and other devices in the power management network, improving the overall system integration.

Installation and Maintenance

Installation Preparation

Before installing the SCM-1, first, ensure that the power supply within the intended installation area falls within the specified 8 – 35 VDC input voltage range of the module. Check the physical location for any environmental factors that could exceed the – 25 °C to + 70 °C operating temperature limit. Clean the installation surface to prevent dust or debris from interfering with the module’s performance. When connecting the communication cables, make sure to use proper shielded cables for RS 485 connections to minimize electromagnetic interference. Follow the wiring diagrams provided in the product manual carefully to correctly connect all the input and output signals related to voltage, current measurement, and control functions.

Maintenance Recommendations

Regularly inspect the SCM-1 for any signs of physical damage, such as cracks in the casing or loose connections. Check the communication status by periodically verifying that data is being transmitted correctly via the RS 485 and Modbus interfaces. Calibrate the measurement functions of the module at least once a year to maintain the ± 0.5% measurement accuracy. This can be done using standard calibration equipment and following the calibration procedures in the product documentation. If any issues are detected during operation, such as incorrect synchronization or inaccurate parameter measurements, refer to the troubleshooting guide provided by DEIF. In case of a software – related problem, check for available firmware updates on DEIF’s official website and follow the update instructions carefully to ensure optimal performance.

SCM-1

Product Warranty

Our company provides a quality warranty service for the DEIF SCM-1 Synchronizing/Measuring Module for a period of one year. This warranty covers hardware failures that are not caused by human factors. If, during the warranty period, the SCM-1 shows abnormal performance or fails to function as intended, we will promptly provide a replacement service. For customers with urgent requirements or in need of discontinued models, our extensive global supply chain network enables us to quickly respond to the procurement needs for scarce spare parts. We are committed to providing reliable services to support the continuous and stable operation of industrial power systems, ensuring that our customers can rely on the SCM-1 module with confidence.

DEIF IPM-1 System module

DEIF CM-2 Server

DEIF DELOMATIC-3 DGU2 PLC

DEIF OPM-1 module

DEIF PSM-1 Controller module

WOODWARD 9907-1200 DCS card

ALSTOM CMP1838 TRVCO62345000 CP00005202 DI card

EATON CS-TX3-3. 81X2.54-64TW controller

ASML MC1AB37 4022.437.1856 Inverter operating panel

FOXBORO P0926GU FBM230 Communication module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: