Description

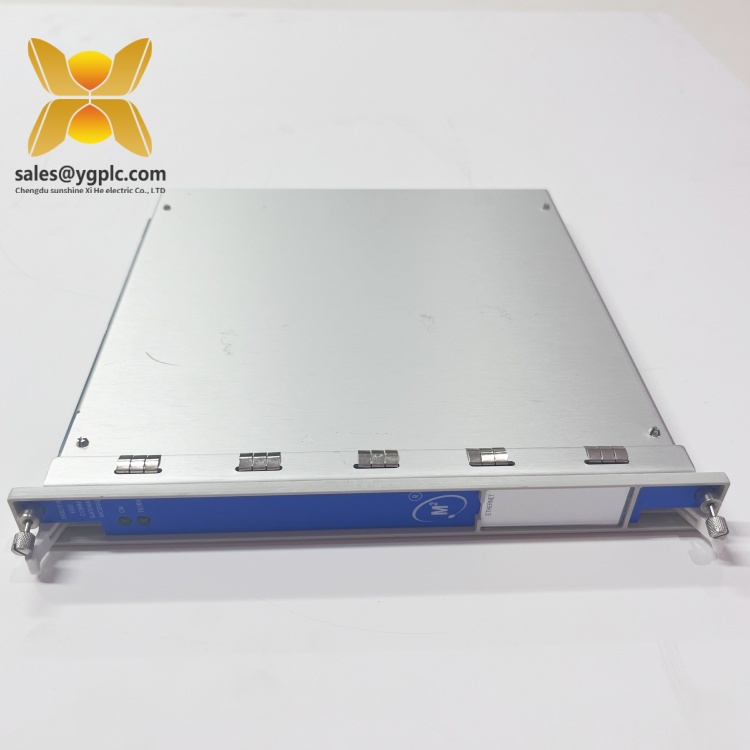

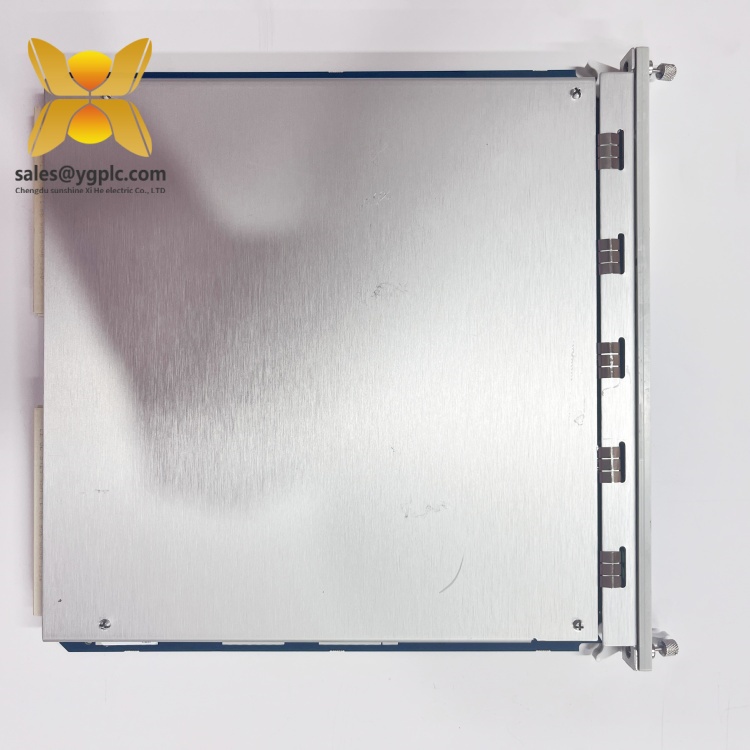

Bently Nevada 3500/91M 190782-01 Communication Gateway Module

Product Overview:Bently Nevada 3500/91M 190782-01

The Bently Nevada 3500/91M 190782-01 is a high-performance Communication Gateway Module designed as the critical interface between Bently Nevada’s 3500 Series Machinery Protection System and higher-level industrial control systems. Serving as the backbone for data integration in rotating equipment monitoring, this module enables seamless transmission of real-time vibration, displacement, and process data from the 3500 framework to distributed control systems (DCS), programmable logic controllers (PLCs), or enterprise-level monitoring platforms. As an essential component of the 3500 Series, the 3500/91M 190782-01 ensures compatibility with all 3500 modules, facilitating comprehensive machinery health management in industries such as oil & gas, power generation, and manufacturing.

Featuring dual independent communication channels, the 3500/91M 190782-01 supports multiple protocols including MODBUS RTU, MODBUS TCP, and Ethernet/IP, allowing flexible integration with diverse automation ecosystems. Its rugged design complies with industry standards like API 670 and ISO 10816, ensuring reliable operation in harsh environments with temperatures ranging from -40°C to +85°C. The module’s plug-and-play functionality reduces installation complexity, while built-in diagnostics provide real-time status feedback, minimizing downtime and enhancing maintenance efficiency. By bridging the gap between field-level monitoring and enterprise-level control, the 3500/91M 190782-01 empowers organizations to implement proactive maintenance strategies, reduce unplanned outages, and extend equipment lifespan.

In industrial automation architectures, the Bently Nevada 3500/91M 190782-01 acts as a data concentrator, aggregating measurements from modules like the 3500/42M Vibration Monitor and 3500/25 Keyphasor to enable holistic machinery diagnostics. Its redundant power supply and communication paths enhance system resilience, making it indispensable for mission-critical applications where data integrity and uptime are non-negotiable. Whether deployed in standalone systems or large-scale industrial complexes, this module ensures continuous, reliable data flow, supporting informed decision-making and operational excellence.

Technical Specifications:Bently Nevada 3500/91M 190782-01

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/91M 190782-01 |

| Manufacturer | Bently Nevada |

| Product Type | Communication Gateway Module |

| Protocol Support | MODBUS RTU, MODBUS TCP, Ethernet/IP, Profibus DP |

| Physical Dimensions | 10.16 cm (H) × 16.51 cm (W) × 22.86 cm (D) |

| Weight | 1.2 kg |

| Power Supply | 19.2–26.4 VDC (redundant inputs) |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in 3500 Series enclosure |

| Communication Ports | 2 × Ethernet (10/100 Mbps), 2 × RS-485 |

| Data Update Rate | ≤100 ms |

| Certifications | CE, UL, API 670 |

BENTLY 3500-91M 190782-01

Key Features and Advantages:Bently Nevada 3500/91M 190782-01

Multi-Protocol Flexibility: The 3500/91M 190782-01 supports simultaneous communication via multiple protocols, eliminating the need for separate gateways and simplifying integration with legacy and modern control systems. This versatility reduces hardware costs and streamlines system architecture.

Redundant Design: With dual power inputs and independent communication channels, the module ensures uninterrupted operation even in the event of a single component failure. Redundancy is configurable via Bently Nevada’s 3500/44M Configuration Software, enhancing system reliability in critical applications.

High-Speed Data Transfer: Capable of updating data at rates as low as 100 ms, the module delivers real-time machinery health insights to support rapid decision-making. Its high-throughput Ethernet ports facilitate seamless integration with SCADA systems for remote monitoring and diagnostics.

Plug-and-Play Integration: Designed specifically for the 3500 Series framework, the 3500/91M 190782-01 requires no additional programming for basic functionality, reducing commissioning time. Advanced users can customize data mapping and protocol parameters via the module’s configuration interface.

Rugged Industrial Construction: The module’s durable enclosure and conformal coating protect against dust, moisture, and electromagnetic interference, ensuring long-term performance in harsh industrial environments. Its shock and vibration resistance (compliant with IEC 60068-2-6) makes it suitable for offshore platforms, refineries, and heavy manufacturing sites.

Comprehensive Diagnostics: Built-in LED indicators and fault logging provide real-time visibility into communication status, power supply health, and data integrity. Alarms can be configured to trigger via the 3500 Series’ relay modules, enabling proactive response to connectivity issues.

BENTLY 3500-91M 190782-01

Application Areas:Bently Nevada 3500/91M 190782-01

The Bently Nevada 3500/91M 190782-01 is essential for industries reliant on precise machinery monitoring and control:

- Oil & Gas: Deployed in offshore rigs, pipelines, and refineries to transmit vibration data from turbines and compressors to central control systems, enabling early detection of bearing wear, misalignment, or cavitation.

- Power Generation: Integrates with steam and gas turbine control systems in power plants, providing real-time data to optimize load balancing, fuel efficiency, and compliance with grid stability standards.

- Manufacturing: Used in automotive, chemical, and pulp & paper facilities to monitor high-speed rotating equipment (e.g., motors, fans, gearboxes), reducing downtime through predictive maintenance.

- Mining and Metals: Supports continuous monitoring of conveyor systems, crushers, and milling machines, minimizing unplanned outages in mineral processing operations.

Specific applications include:

- Predictive Maintenance Systems: Aggregates data from multiple 3500 modules to create comprehensive machinery health reports, enabling data-driven maintenance scheduling.

- Safety Instrumented Systems (SIS): Provides critical machinery status inputs to emergency shutdown systems, ensuring rapid response to fault conditions.

- Remote Operations Centers: Facilitates real-time data streaming to cloud-based platforms, allowing remote monitoring and diagnostics for geographically dispersed assets.

BENTLY 3500-91M 190782-01

Related Products:Bently Nevada 3500/91M 190782-01

- 3500/42M Vibration Monitor: Works alongside the 3500/91M 190782-01 to measure vibration and axial displacement, providing raw data for transmission via the gateway.

- 3500/25 Keyphasor Module: Supplies reference signals for phase-locked vibration analysis, complementing the gateway’s data integration capabilities.

- 3500/32M Relay Module: Triggers alarms or shutdowns based on data from the 3500/91M 190782-01, enhancing safety and control.

- 3500/05 Rack Enclosure: Houses the 3500/91M 190782-01 and other 3500 modules, providing a centralized platform for machinery protection.

- 3500/44M Configuration Software: Used to program the gateway’s protocol settings, data mapping, and redundancy logic.

- 3300 XL Proximity Probes: Sensors that interface with the 3500 Series to measure shaft vibration and position, feeding data into the 3500/91M 190782-01.

- 3500/53 Speed/Torque Module: Measures rotational speed and torque, expanding the gateway’s data portfolio for comprehensive machinery diagnostics.

- 3500/61C Rack Interface Module: Manages power distribution and communication within the 3500 Series rack, ensuring stable operation of the gateway.

Installation and Maintenance:Bently Nevada 3500/91M 190782-01

Installation Preparation:

Before installing the 3500/91M 190782-01, verify that the 3500 Series rack is properly grounded and powered. Ensure compatibility with existing network infrastructure, using shielded Ethernet or RS-485 cables to minimize interference. Mount the module in an available slot within the rack, securing it with the provided hardware. Connect redundant power supplies and configure network settings using Bently Nevada’s 3500/44M Software, ensuring IP address consistency with the target control system.

Before installing the 3500/91M 190782-01, verify that the 3500 Series rack is properly grounded and powered. Ensure compatibility with existing network infrastructure, using shielded Ethernet or RS-485 cables to minimize interference. Mount the module in an available slot within the rack, securing it with the provided hardware. Connect redundant power supplies and configure network settings using Bently Nevada’s 3500/44M Software, ensuring IP address consistency with the target control system.

Maintenance Recommendations:

- Routine Checks: Inspect the module monthly for loose connections, overheating, or physical damage. Use the module’s web interface to review communication logs and error statistics.

- Firmware Updates: Periodically update the module’s firmware to access new protocol support, security patches, and performance improvements, following the manufacturer’s guidelines.

- Redundancy Testing: Conduct quarterly tests of redundant power supplies and communication paths to ensure failover functionality. Document test results for compliance and maintenance records.

- Cleaning: Dust the module’s vents and connectors annually to prevent heat buildup, using compressed air or a static-free cloth.

BENTLY 3500-91M 190782-01

Product Warranty:Bently Nevada 3500/91M 190782-01

Our company provides a 12-month quality warranty for the Bently Nevada 3500/91M 190782-01, covering hardware defects under normal use. In the event of performance issues, we offer prompt replacement services to minimize operational disruption. For discontinued or hard-to-find models, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick turnaround for urgent needs. Our technical support team is available 24/7 to assist with installation, configuration, and troubleshooting, delivering reliable solutions to keep your automation systems running efficiently.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

BENTLY 3500/92 136180-01 Frequency converter module

BENTLY 3500/15 114M5330-01 Power module

BENTLY 3500/77M 176449-07 System module

BENTLY 3500/54 133396-01 Server

BENTLY 3500/32 125720-01 PLC

BENTLY 3500/45 176449-04 module

BENTLY 3500/65 145988-02 Controller module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: