Description

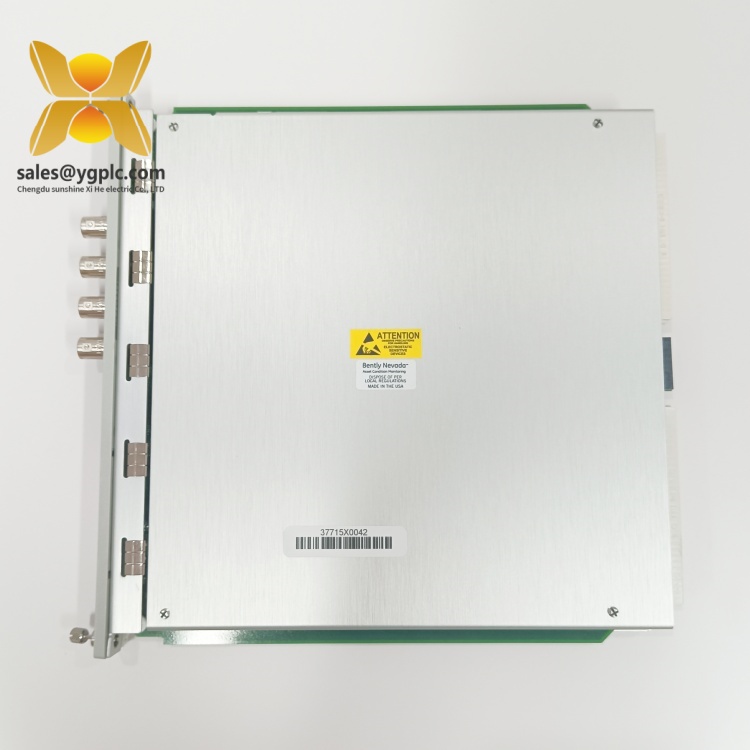

BENTLY NEVADA 3500/45 176449-04 Machinery Protection Module

Product Overview : BENTLY NEVADA 3500/45 176449-04

The :BENTLY NEVADA 3500/45 176449-04 machinery protection module is a high-reliability industrial component designed for critical rotating machinery monitoring within Bently Nevada’s renowned 3500 Series. As a four-channel protection module, it specializes in real-time monitoring of parameters such as vibration, axial displacement, and velocity, serving as a cornerstone for predictive maintenance strategies in industrial automation systems. Engineered to meet API 670 standards, this module ensures compliance with global safety and performance requirements, making it indispensable for maintaining the operational integrity of turbines, compressors, and generators in harsh industrial environments.

The 3500/45 176449-04 features a robust design with dual redundant power inputs and relay outputs, providing fail-safe protection against machinery failures. It accepts signals from proximity probes and seismic sensors, processing them to deliver precise measurements with ±1% accuracy. The module’s Modbus RTU/TCP communication interface enables seamless integration with distributed control systems (DCS) and supervisory control and data acquisition (SCADA) platforms, allowing real-time data transmission for remote diagnostics and system optimization. With its rack-mounted design (160 mm height x 110 mm width x 250 mm depth), the 3500/45 176449-04 fits into the 3500 Series Rack System, a scalable platform supporting up to 56 monitoring channels for complex industrial setups.

In automation ecosystems, the 3500/45 176449-04 acts as a critical layer of protection, converting raw sensor data into actionable insights to prevent unplanned downtime. Its ability to trigger alarms and shutdown sequences based on user-programmable setpoints ensures proactive mitigation of risks such as bearing wear or shaft misalignment. By combining high precision with rugged durability (-30°C to +65°C operating temperature), this module enhances the reliability of high-value assets across industries, reducing maintenance costs and extending equipment lifespan.

Technical Specifications : BENTLY NEVADA 3500/45 176449-04

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/45 176449-04 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Machinery Protection Module |

| Channels | 4 (configurable for vibration/displacement) |

| Input Voltage | 24V DC ±10% |

| Communication Protocol | Modbus RTU/TCP |

| Physical Dimensions | 160 mm (H) x 110 mm (W) x 250 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | 3500 Rack System (19-inch rack compatible) |

| Country of Origin | United States |

Bently 350045 176449-04

Main Features and Advantages : BENTLY NEVADA 3500/45 176449-04

Comprehensive Machinery Health Monitoring: The 3500/45 176449-04 supports simultaneous monitoring of up to four independent channels, each configurable for radial vibration, axial displacement, or velocity measurements. This versatility allows it to cater to diverse machinery types, from steam turbines in power plants to centrifugal compressors in refineries, by providing a holistic view of equipment health.

Redundant Safety Architecture: Built with dual redundant power supplies and relay outputs, the module ensures continuous operation even in the event of a single component failure. The redundant design meets the highest safety integrity levels, making it suitable for applications where system downtime is not an option, such as offshore oil platforms or nuclear power facilities.

High Precision and Compliance: Designed to API 670 standards, the module delivers measurements with ±1% accuracy, ensuring reliable data for critical decision-making. Its compliance with international safety protocols simplifies integration into global industrial projects, while the rugged IP20-rated enclosure protects against dust and light moisture, enhancing durability in harsh environments.

Scalable Integration: As part of the 3500 Series, the 3500/45 176449-04 seamlessly integrates with other modules like the 3500/92 communication gateway and 3500/22M interface module, forming a cohesive monitoring system. This scalability allows users to start with basic configurations and expand to complex setups as their needs evolve, reducing upfront investment costs.

User-Friendly Interface: The module features intuitive configuration via Bently Nevada’s 3500 Rack Configuration Software, enabling quick setup of alarm thresholds and measurement ranges. Real-time status indicators on the front panel provide instant visibility into module health, minimizing troubleshooting time and enhancing operational efficiency.

Bently 350045 176449-04

Application Areas : BENTLY NEVADA 3500/45 176449-04

The BENTLY NEVADA 3500/45 176449-04 machinery protection module is deployed across industries requiring stringent machinery monitoring:

-

Power Generation: In thermal and gas turbine plants, the module monitors shaft vibration and displacement to detect early signs of imbalance or bearing degradation. For example, in a combined cycle power plant, the 3500/45 176449-04 ensures stable operation of generators by triggering alarms when vibration levels exceed safe limits, preventing catastrophic failures and maintaining grid stability.

-

Oil and Gas: Used in refineries and offshore platforms, the module safeguards compressors and pumps by monitoring axial movement and velocity. In a liquefied natural gas (LNG) facility, it helps maintain optimal performance of cryogenic pumps, ensuring continuous production and compliance with environmental safety standards.

-

Industrial Manufacturing: In manufacturing settings, the module is integrated into CNC machines and conveyor systems to monitor rotational equipment health. For instance, in a steel mill, it tracks vibration in rolling mills to prevent material defects and reduce downtime caused by unexpected machinery failures.

-

Water and Wastewater Treatment: Deployed in pump stations and treatment plants, the 3500/45 176449-04 monitors the condition of large motors and agitators. By detecting abnormal vibration patterns, it helps optimize maintenance schedules and ensure uninterrupted water supply or wastewater processing.

-

Aerospace and Defense: In testing facilities and aircraft ground support equipment, the module provides precise vibration analysis for jet engines and propulsion systems, ensuring compliance with rigorous performance and safety standards.

Related Products : BENTLY NEVADA 3500/45 176449-04

- 3500/42M Vibration Monitoring Module: A six-channel variant with advanced vibration analysis capabilities, complementing the 3500/45 176449-04 in complex monitoring setups.

- 3500/92 Communication Gateway: Enables Modbus TCP/IP connectivity for the 3500/45 176449-04, facilitating data integration with cloud-based analytics platforms.

- 3500/22M Interface Module: Provides power and signal conditioning for proximity probes, serving as a critical companion to the 3500/45 176449-04 in sensor-to-module connectivity.

- 3500/32 Relay Module: Offers 16-channel relay outputs for alarm signaling, enhancing the 3500/45 176449-04’s safety shutdown capabilities.

- 3500/53 Displacement Module: Specializes in precise displacement measurements, ideal for applications requiring dual-channel monitoring alongside the 3500/45 176449-04.

- 3500/05 Rack Enclosure: Houses the 3500/45 176449-04 and other 3500 Series modules, providing a robust and organized hardware platform.

- 3300 XL Proximity Probe System: A high-accuracy sensor suite sets with the 3500/45 176449-04 to measure shaft displacement and vibration.

Bently 350045 176449-04

Installation and Maintenance : BENTLY NEVADA 3500/45 176449-04

Pre-installation Preparations:

Before installing the 3500/45 176449-04, ensure the 3500 Rack System is properly grounded and powered with 24V DC. Verify compatibility with sensor types (e.g., 3300 XL proximity probes) and configure the module using Bently Nevada’s official software. Mount the module in the rack, securing it with the provided brackets, and connect sensor cables to the designated terminals, ensuring correct polarity and torque specifications. Finally, establish communication with the control system via the Modbus interface, following the manufacturer’s wiring diagrams to avoid signal interference.

Before installing the 3500/45 176449-04, ensure the 3500 Rack System is properly grounded and powered with 24V DC. Verify compatibility with sensor types (e.g., 3300 XL proximity probes) and configure the module using Bently Nevada’s official software. Mount the module in the rack, securing it with the provided brackets, and connect sensor cables to the designated terminals, ensuring correct polarity and torque specifications. Finally, establish communication with the control system via the Modbus interface, following the manufacturer’s wiring diagrams to avoid signal interference.

Maintenance Recommendations:

- Routine Inspections: Conduct monthly visual checks for loose connections, damaged cables, or overheating. Clean the module’s ventilation slots to prevent dust accumulation, which can affect thermal performance.

- Calibration: Annually calibrate sensors and the 3500/45 176449-04 using Bently Nevada’s calibration tools to maintain measurement accuracy. Document calibration results for compliance and traceability.

- Firmware Updates: Periodically review Bently Nevada’s technical updates and apply firmware upgrades to the module to access new features or security patches, ensuring compatibility with evolving automation systems.

- Redundancy Testing: Quarterly test the module’s redundant power and relay channels to confirm failover functionality. Replace any faulty components immediately using genuine spares to maintain system reliability.

Bently 350045 176449-04

Product Warranty : BENTLY NEVADA 3500/45 176449-04

Our company offers a 12-month quality warranty for the BENTLY NEVADA 3500/45 176449-04 machinery protection module, covering non-human-induced hardware defects. In the rare event of performance anomalies or functional failures during the warranty period, we provide prompt replacement services to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of spare parts, leveraging 17 years of industry expertise to support critical industrial operations.

Beyond warranty, we deliver comprehensive technical support, including installation guidance and troubleshooting assistance, to ensure optimal performance throughout the module’s lifecycle. Our commitment to quality and reliability makes us a trusted partner for industrial control solutions, offering competitive pricing and fast delivery to meet the diverse needs of our global clientele.

Note: All product names, logos, and brands are proprietary to their respective owners. This document is for informational purposes and does not substitute official technical documentation. Always refer to Bently Nevada’s manuals for detailed installation and operational guidelines.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

BENTLY 3500-20 monitor

BENTLY 135031-01 rack

BENTLY 3500/44M 140734-03 Remote module

BENTLY 3500/54 133396-01 Main processor

BENTLY 3500/92 136180-01 Pulse input

BENTLY 3500/15 114M5330-01 Analog quantity

BENTLY 3500/77M 176449-07 Digital quantity

Siemens 6DD2920-0AM0 AI card

Siemens 6DD2920-0BB0 Pulse encoder

WOODWARD 9907-1200 Control system power supply

EATON CS-TX3-3. 81X2.54-64TW Main frame

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: