Description

Product Overview

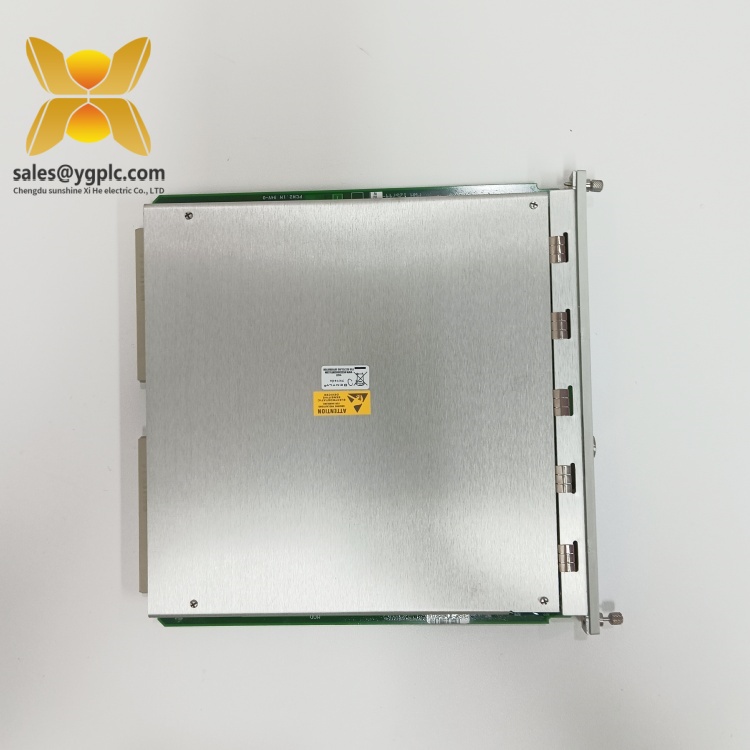

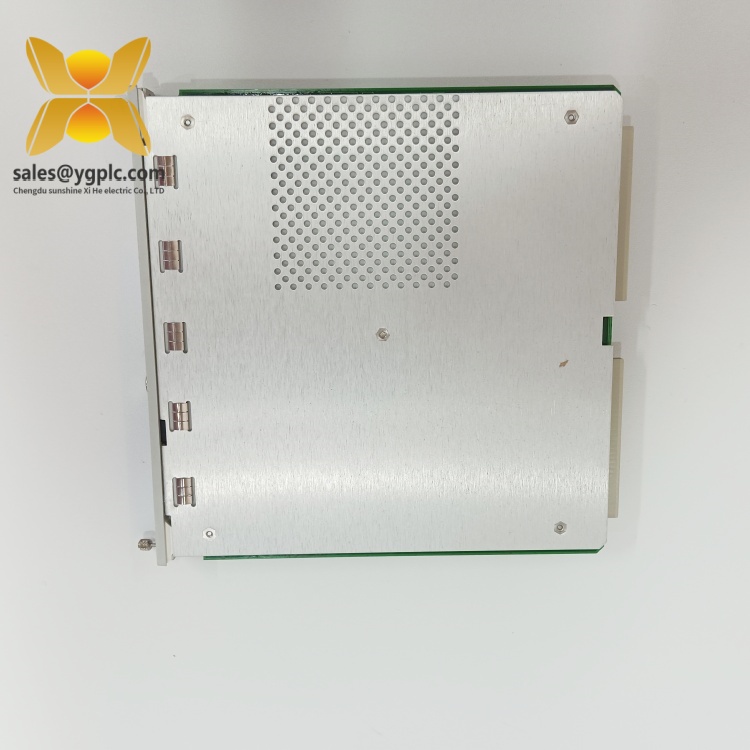

The Bently Nevada 3500/20 Rack Interface Module is a core component of the 3500 Series Machinery Protection System, designed to enable seamless communication and power distribution within industrial automation setups. As a rack interface module, it serves as the backbone of the 3500 system, connecting various monitor modules, power supplies, and communication gateways to ensure unified operation and data integration.

Engineered for high-reliability environments, the 3500/20 supports dual power inputs (24 VDC or 120 VAC) and features redundant communication channels to minimize downtime. Its RS232/RS422 interface allows direct connectivity with external devices, while the DIN rail mounting design (9.5 x 0.96 x 9.52 inches) ensures easy integration into standard control cabinets. The module’s NEMA 4X/IP66-rated enclosure withstands harsh conditions, including dust, moisture, and corrosive chemicals, making it suitable for use in oil refineries, power plants, and other industrial settings.

In automation systems, the 3500/20 acts as a central hub for data aggregation and distribution. It coordinates with modules like the 3500/42M Vibration Monitoring Module and 3500/92 Communication Gateway to deliver real-time machinery health data, enabling predictive maintenance and fault diagnosis. By ensuring stable power delivery and reliable communication, this module enhances the overall efficiency and safety of rotating equipment, such as turbines, compressors, and pumps.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/20 |

| Manufacturer | Bently Nevada |

| Product Type | Rack Interface Module |

| Input Voltage | 24 VDC or 120 VAC |

| Output Voltage | 5 VDC (regulated) |

| Communication Protocol | RS232/RS422 |

| Physical Dimensions | 9.5 x 0.96 x 9.52 inches |

| Mounting Type | DIN rail (3500 Series rack-compatible) |

| Weight | 0.91 kg |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5–95% non-condensing |

| Protection Rating | NEMA 4X/IP66 |

| Redundancy | Dual power inputs |

| LED Indicators | Power status, communication activity |

3500/20

Key Features and Advantages

Dual Power Architecture: The 3500/20 supports both 24 VDC and 120 VAC inputs, ensuring continuous operation even if one power source fails. This redundancy is critical for applications where downtime is costly, such as oil and gas production.

Robust Communication: With RS232/RS422 interfaces, the module facilitates seamless data exchange between the 3500 system and external devices, including SCADA systems and diagnostic software. This enables remote monitoring and centralized control, enhancing operational efficiency.

Rugged Design: The NEMA 4X/IP66-rated enclosure protects the module from environmental hazards, while the fiberglass construction resists corrosion and vibration. This durability ensures reliable performance in harsh industrial environments.

Flexible Integration: The module’s DIN rail mounting and compact size allow easy installation in space-constrained control panels. It supports multiple monitor modules (e.g., vibration, temperature, speed) and works with Bently Nevada’s System 1 software for advanced machinery health analysis.

Redundancy for Critical Systems: By providing dual power paths and redundant communication channels, the 3500/20 minimizes single points of failure, making it ideal for safety-critical applications like turbine protection systems.

3500/20

Application Areas

The Bently Nevada 3500/20 Rack Interface Module is widely used in industries where machinery reliability is paramount:

- Power Generation: Integrates with steam and gas turbines to monitor vibration, temperature, and speed, ensuring stable energy production and grid synchronization.

- Oil & Gas: Supports compressor stations, refineries, and offshore platforms by enabling real-time data exchange between monitoring modules and control systems.

- Manufacturing: Powers control systems in heavy machinery, such as conveyor belts and CNC machines, optimizing efficiency and reducing maintenance costs.

- Water Treatment: Ensures reliable operation of pumps and blowers in wastewater treatment plants by providing stable power and communication.

- Mining: Distributes power and data to ventilation systems, crushers, and conveyor belts in mining operations, enhancing safety and productivity.

Related Products

- 3500/42M Vibration Monitoring Module: 配套使用 with the 3500/20 to analyze vibration data and detect machinery imbalances or bearing wear.

- 3500/92 Communication Gateway: Expands the 3500/20’s connectivity by enabling integration with industry-standard protocols like Modbus and Ethernet.

- 3500/32 Relay Module: Provides relay outputs for machinery shutdown and alarm functions, complementing the 3500/20 in safety-critical applications.

- 3500/93 Display Interface Module: Offers local or remote visual indicators of system status, enhancing operator visibility.

- 3500/22M Transient Data Interface: Captures high-frequency vibration data for advanced diagnostic analysis, working alongside the 3500/20.

- 3500/95 Display: A standalone display unit that interfaces with the 3500/20 to show real-time machinery health metrics.

- 3500/53 Over-Speed Monitor: Monitors rotational speed and triggers alarms if thresholds are exceeded, integrated via the 3500/20.

- 3500/05 Rack: Houses the 3500/20 and other modules, providing structural support and backplane communication.

3500/20

Installation and Maintenance

Installation Preparation:

Before installing the 3500/20, verify the input voltage matches the power supply (24 VDC or 120 VAC). Clean the DIN rail and ensure proper grounding to minimize electromagnetic interference. Align the module with the rack and secure it using the provided mounting clips. Connect power cables to the terminal blocks, following Bently Nevada’s torque specifications (35A max per terminal). Finally, link the module to adjacent components via the RS232/RS422 connectors, adhering to the wiring guidelines.

Before installing the 3500/20, verify the input voltage matches the power supply (24 VDC or 120 VAC). Clean the DIN rail and ensure proper grounding to minimize electromagnetic interference. Align the module with the rack and secure it using the provided mounting clips. Connect power cables to the terminal blocks, following Bently Nevada’s torque specifications (35A max per terminal). Finally, link the module to adjacent components via the RS232/RS422 connectors, adhering to the wiring guidelines.

Maintenance Recommendations:

- Routine Inspections: Quarterly checks for loose connections, blown fuses, or signs of overheating. Clean the enclosure’s exterior to prevent dust accumulation.

- Power Supply Checks: Annually test the dual power inputs to ensure redundancy is operational. Replace faulty power supplies immediately.

- Communication Testing: Bi-annually verify RS232/RS422 connectivity using Bently Nevada’s SensorVue software to ensure data integrity.

- Firmware Updates: Periodically check Bently Nevada’s official website for firmware updates to access new features and bug fixes.

3500/20

Product Warranty

We provide a 12-month quality warranty for the Bently Nevada 3500/20 Rack Interface Module, covering hardware defects caused by non-human factors. During the warranty period, we will replace any malfunctioning module free of charge. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of scarce spare parts, supporting continuous operation of industrial systems.

With 17 years of expertise in industrial control parts distribution, we guarantee competitive pricing, fast delivery, and reliable technical support. Contact us today to optimize your machinery protection system with the 3500/20 Rack Interface Module.

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not constitute an official technical manual. Always refer to the manufacturer’s documentation for detailed specifications and installation guidelines.

GE CK11CE300 RXM rack

FOXBORO FBM202 P0926EQ Thermoelectric couple

ABB PFVO 102 Double-action switch

TRICONEX DO2401 7400209-030 rack

TRICONEX AI3351 Digital 24VDC output module

ABB PM633 Acquisition card

ABB REF542PLUS Gas turbine card

CONVERTEAM P110-6052 DC/DC

ABB PPC905AE101 3BHE014070R0101 Analog output module

ABB DSPU131 3BSE000355R1 display

ABB GFD233A103 3BHE022294R0103 Relay output

FOXBORO P0926GV FBM231 Optical isolation module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: