Description

BENTLY 3500/77M 176449-07 Product Specification

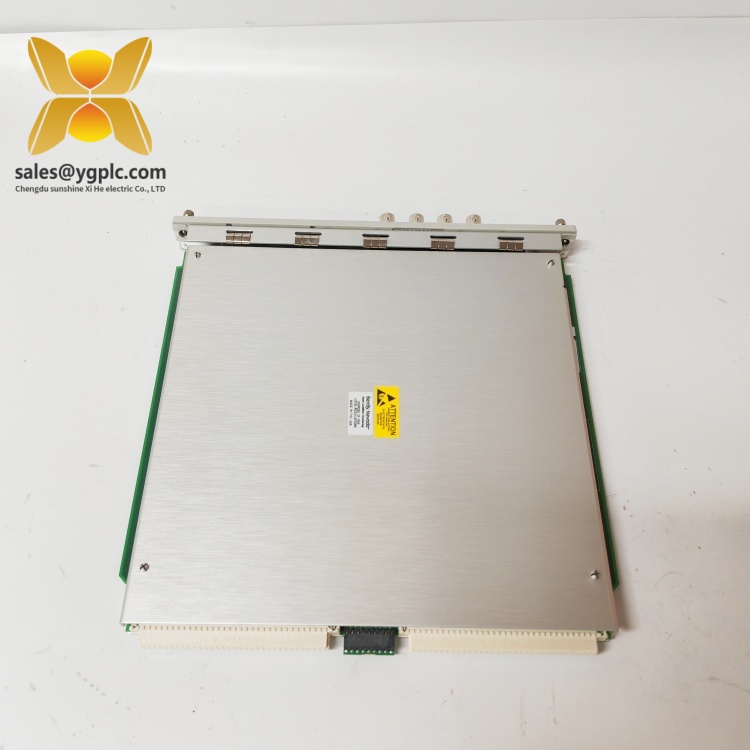

Product Overview:BENTLY 3500/77M 176449-07

The BENTLY 3500/77M 176449-07 is a high-precision dual-channel vibration and displacement monitoring module designed for critical rotating machinery in industrial automation systems. Engineered by BENTLY NEVADA, a global leader in mechanical protection and condition monitoring solutions, this module is part of the renowned 3500 Series Machinery Protection System, a platform trusted in industries requiring reliable detection of machinery faults to prevent downtime and catastrophic failures. The BENTLY 3500/77M 176449-07 serves as a core component in predictive maintenance strategies, enabling real-time monitoring of shaft vibration, casing vibration, and axial displacement in turbines, compressors, and other rotating equipment.

Featuring advanced signal conditioning and digital processing capabilities, the BENTLY 3500/77M 176449-07 accepts inputs from proximity probes, velocity transducers, or accelerometers, converting raw sensor data into actionable measurements. Its dual-channel design allows simultaneous monitoring of two independent parameters (e.g., X and Y axis vibrations), providing comprehensive insight into machinery health. The module integrates seamlessly with the 3500 Series framework, a modular system that supports up to 19 plug-in modules for scalable configuration. By delivering precise, real-time data to supervisory control systems, the BENTLY 3500/77M 176449-07 empowers industries to optimize maintenance schedules, reduce operational risks, and extend equipment lifespan.

In automation systems, the BENTLY 3500/77M 176449-07 acts as a critical link between field sensors and higher-level control architectures, such as distributed control systems (DCS) or condition monitoring software. Its rugged design ensures reliable performance in harsh environments, with temperature tolerance ranging from -40°C to +85°C and immunity to electromagnetic interference. By combining high-resolution analog-to-digital conversion with robust mechanical construction, this module sets a standard for accuracy and durability in machinery protection applications.

Technical Specifications:BENTLY 3500/77M 176449-07

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 3500/77M 176449-07 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Dual-Channel Vibration and Displacement Monitoring Module |

| Physical Dimensions | 171 mm (height) × 48 mm (width) × 241 mm (depth) |

| Weight | 0.9 kg |

| Input Types | Proximity probes (AC/DC), velocity transducers, accelerometers |

| Signal Outputs | 4–20 mA analog, digital via 3500 Series communication modules |

| Power Supply | 24 VDC ±15% (from 3500 Series framework) |

| Communication | Compatible with 3500/92 Ethernet Gateway for Modbus TCP/IP or BENTLY ProLink |

| Operating Temperature | -40°C to +85°C |

| Vibration Resistance | 5–2000 Hz, 5 g (IEC 60068-2-64) |

| Certifications | CE, API 670 (Machinery Protection Systems) |

3500/77M 176449-07

Main Features and Advantages:BENTLY 3500/77M 176449-07

Dual-Channel Precision: The BENTLY 3500/77M 176449-07 monitors two parameters simultaneously, such as radial vibration on two orthogonal axes, providing a complete picture of shaft dynamics. This dual functionality reduces hardware requirements and simplifies system integration, making it ideal for space-constrained applications.

Advanced Signal Processing: The module incorporates high-pass and low-pass filters, trend analysis, and peak hold capabilities, enabling users to distinguish between normal operational vibrations and abnormal patterns indicative of wear, misalignment, or imbalance. Its 16-bit analog-to-digital conversion ensures measurement accuracy within ±0.5% of full scale.

Seamless System Integration: As part of the 3500 Series, the BENTLY 3500/77M 176449-07 shares a common power supply, communication backbone, and user interface with other modules (e.g., controllers, transmitters). This modular design allows for easy expansion or replacement, minimizing downtime during system upgrades.

Rugged Industrial Design: Built to withstand extreme temperatures, vibrations, and electrical noise, the module features a metal enclosure and conformal-coated circuitry, ensuring reliability in demanding environments like oil refineries, power plants, and manufacturing facilities.

Predictive Maintenance Support: By providing real-time data on machinery health, the BENTLY 3500/77M 176449-07 supports condition-based maintenance strategies, allowing operators to schedule repairs proactively rather than react to failures. This approach reduces unscheduled downtime and maintenance costs while improving overall plant efficiency.

3500/77M 176449-07

Application Areas:BENTLY 3500/77M 176449-07

The BENTLY 3500/77M 176449-07 is indispensable in industries where rotating machinery reliability is non-negotiable:

-

Oil and Gas:

- Monitors compressors, pumps, and turbines in upstream production, midstream pipelines, and downstream refineries.

- Detects early signs of bearing wear or seal leakage, preventing costly shutdowns and environmental incidents.

-

Power Generation:

- Used in steam and gas turbines, generators, and auxiliary systems to ensure stable energy production.

- Supports compliance with ISO 10816 vibration standards by providing traceable, calibrated measurements.

-

Chemical and Petrochemical:

- Controls critical processes in reactors and distillation columns by monitoring agitators and centrifuges.

- Enables safe operation in hazardous environments through its rugged, explosion-proof compatible design.

-

Manufacturing and Metals:

- Optimizes production lines by monitoring high-speed rotating equipment, such as motors and gearboxes.

- Reduces unplanned downtime in steel mills and paper plants by identifying misalignment or resonance issues before they escalate.

Related Products:BENTLY 3500/77M 176449-07

- BENTLY 3500/22M 176471-01: A 3500 Series main processor module that manages data from the BENTLY 3500/77M 176449-07, providing alarm logic and system synchronization.

- BENTLY 3500/92 177143-01: An Ethernet communication gateway that enables the BENTLY 3500/77M 176449-07 to transmit data to enterprise-level systems via Modbus TCP/IP or BENTLY ProLink.

- BENTLY 3500/42M 176436-01: A four-channel vibration module for applications requiring additional monitoring points, complementing the dual-channel design of the 3500/77M.

- BENTLY 330104-00-05-10-02-00: A proximity probe kit compatible with the 3500/77M, designed for non-contact measurement of shaft displacement and vibration.

- BENTLY 3500/05 174640-01: A 3500 Series rack power supply module that ensures stable power delivery to the 3500/77M and other framework components.

3500/77M 176449-07

Installation and Maintenance:BENTLY 3500/77M 176449-07

Pre-installation Preparation:

Before installing the BENTLY 3500/77M 176449-07, ensure the following:

Before installing the BENTLY 3500/77M 176449-07, ensure the following:

- Verify the 3500 Series framework is powered off and grounded to prevent electrostatic discharge (ESD) damage.

- Align the module with the framework’s backplane connectors and secure it using the provided captive screws.

- Connect sensor cables to the module’s terminal blocks, following the wiring diagram in the user manual to ensure proper polarity and shielding.

Maintenance Recommendations:

- Regularly inspect the module’s LED indicators to confirm operational status (e.g., power, communication, alarm conditions).

- Perform annual calibration using BENTLY NEVADA’s 3500 System Calibration Tool to ensure measurement accuracy.

- Update firmware periodically via the 3500 Series software to access the latest diagnostic features and compatibility updates.

- In high-dust environments, clean the module’s ventilation slots using compressed air to prevent overheating.

3500/77M 176449-07

Product Warranty:BENTLY 3500/77M 176449-07

Our company provides a one-year quality warranty for the BENTLY 3500/77M 176449-07, covering hardware defects unrelated to misuse or environmental damage. During the warranty period, we will replace any defective module promptly to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid access to rare or obsolete parts, supporting the long-term viability of your industrial systems. Trust in our 17 years of expertise in industrial control solutions to deliver reliable, responsive service for all your automation needs.

Note: This product description is based on technical documentation and industry applications. For detailed operational guidelines, refer to the official BENTLY NEVADA 3500 Series user manual or contact our technical support team.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: