Description

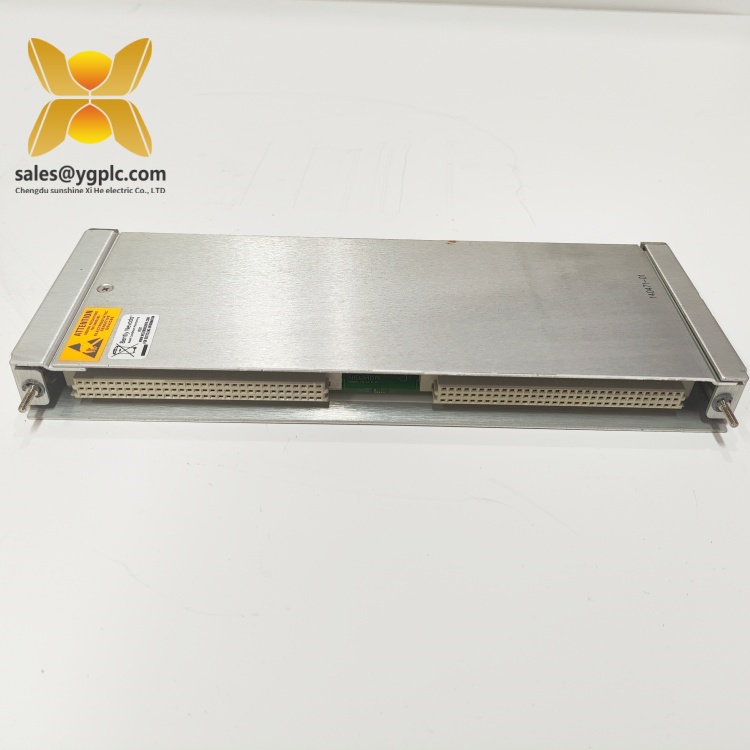

BENTLY 3500/70 140471-01 Temperature Monitoring Module

Product Overview: BENTLY 3500/70 140471-01

The BENTLY 3500/70 140471-01 temperature monitoring module is a high-precision industrial component designed for critical machinery health management within Bently Nevada’s 3500 Series Machinery Health Monitoring System. As a core module in this advanced platform, the 3500/70 140471-01 specializes in real-time temperature surveillance, enabling proactive maintenance and fault prevention in rotating equipment such as turbines, compressors, and motors. This module integrates seamlessly with other 3500 Series components, forming a comprehensive solution for monitoring thermal conditions that impact equipment reliability and operational safety.

Engineered for industrial robustness, the 3500/70 140471-01 supports up to 16 temperature channels, accommodating RTDs (Resistance Temperature Detectors) and thermocouples to measure both surface and internal temperatures. Its linearized temperature output (4–20 mA or digital via Modbus) ensures accurate data transmission to PLCs, DCS systems, or SCADA platforms, while configurable alarm and trip thresholds enable immediate response to abnormal thermal trends. The module’s hot-swappable design and dual-redundant power supply (24V DC) guarantee uninterrupted operation during maintenance or power fluctuations, minimizing downtime in mission-critical applications.

In automation ecosystems, the 3500/70 140471-01 acts as a cornerstone of predictive maintenance strategies. By continuously monitoring temperature parameters—such as bearing temperatures, winding hotspots, or process fluid temperatures—it helps identify issues like lubrication failure, misalignment, or overloading before they escalate into costly breakdowns. Its rugged construction (IP20 protection, -40°C to +85°C operating range) and compliance with API 670 standards make it suitable for harsh environments, including oil refineries, power plants, and heavy manufacturing facilities.

Technical Specifications: BENTLY 3500/70 140471-01

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/70 140471-01 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Temperature Monitoring Module |

| Input Channels | 16 channels (RTD/thermocouple) |

| Temperature Range | -200°C to +1370°C (depending on sensor type) |

| Output Signals | 4–20 mA, Modbus RTU/TCP |

| Power Supply | 24V DC (dual redundant) |

| Physical Dimensions | 160 mm (H) × 110 mm (W) × 250 mm (D) |

| Weight | 1.3 kg |

| Operating Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | 3500 Rack (slot-compatible) |

| Compliance | API 670, IEC 61000-6-2/-6-3 |

| Country of Origin | United States |

3500/70 140471-01

Main Features and Advantages: BENTLY 3500/70 140471-01

Multi-Channel Precision Monitoring: The 3500/70 140471-01 supports simultaneous monitoring of up to 16 temperature points, allowing comprehensive analysis of thermal patterns across complex machinery. Its advanced signal conditioning ensures minimal noise interference, delivering reliable measurements even in high-vibration environments.

Flexible Sensor Compatibility: With configurable inputs for both RTDs (e.g., Pt100) and thermocouples (e.g., J, K, T types), the module adapts to diverse sensor setups, making it versatile for various industrial applications. This flexibility reduces the need for multiple specialized modules, simplifying system design and inventory management.

Real-Time Alarming and Redundancy: The module’s programmable alarm and trip thresholds trigger both local relays and remote alerts when temperature limits are exceeded, enabling rapid response to developing issues. Dual redundant power supplies and hot-swappable functionality enhance system availability, ensuring continuous operation in critical scenarios.

Seamless Integration and Data Management: Compatible with Bently Nevada’s 3500 Series software, the 3500/70 140471-01 allows users to configure channels, view trend data, and generate reports via a unified interface. Its Modbus connectivity facilitates integration with third-party systems, supporting centralized monitoring and analytics for improved operational visibility.

Industrial-Grade Reliability: Built with a rugged metal enclosure and designed to withstand harsh conditions, the module resists dust, moisture, and electromagnetic interference. Its wide temperature range and compliance with industry standards ensure consistent performance in challenging environments, from offshore platforms to steel mills.

3500/70 140471-01

Application Areas: BENTLY 3500/70 140471-01

The BENTLY 3500/70 140471-01 temperature monitoring module is indispensable for industries where thermal management is critical to operational safety and efficiency:

- Power Generation: Monitors steam turbine bearings, generator windings, and heat exchangers in thermal and nuclear power plants, preventing overheating and ensuring optimal energy production.

- Oil and Gas: Deployed in compressors, pumps, and refining equipment to detect temperature anomalies in harsh, corrosive environments, such as offshore platforms or petrochemical plants.

- Manufacturing: Used in CNC machines, extruders, and conveyor systems to maintain temperature control in production processes, ensuring product quality and reducing unplanned downtime.

- Water Treatment: Installed in pumps and blowers to monitor thermal performance in wastewater treatment facilities, ensuring compliance with environmental regulations and continuous operation.

- Aerospace and Defense: Supports temperature monitoring in aircraft ground support equipment and military machinery, where precise thermal control is essential for mission readiness.

Related Products: BENTLY 3500/70 140471-01

- 3500/22M Interface Module: Connects the 3500/70 140471-01 to sensors, providing signal conditioning and isolation for accurate temperature measurements.

- 3500/92M Communication Gateway: Enables Ethernet-based data transmission from the 3500/70 140471-01 to cloud platforms or HMIs, facilitating remote diagnostics and predictive maintenance.

- 3500/05 Rack Enclosure: Houses the 3500/70 140471-01 and other 3500 Series modules, offering mechanical support and centralized power distribution.

- 3500/15 Power Supply Module: Provides redundant power to the 3500/70 140471-01, ensuring stable operation during power fluctuations.

- 3500/42M Vibration Monitoring Module: Complements the 3500/70 140471-01 by integrating vibration and temperature data for comprehensive machinery health analysis.

- 3500/32 Relay Module: Works alongside the 3500/70 140471-01 to trigger alarm or trip actions based on temperature thresholds, enhancing system safety.

3500/70 140471-01

Installation and Maintenance: BENTLY 3500/70 140471-01

Pre-installation Preparations:

Before installing the 3500/70 140471-01, ensure the 3500 Rack is properly grounded and the power supply (24V DC) is verified. Clean the rack slot and slide the module into place, securing it with retention brackets. Connect sensor cables to the designated terminal blocks, following the wiring diagram for RTD or thermocouple configurations. Configure channel parameters (e.g., sensor type, scaling, alarm thresholds) using Bently Nevada’s 3500 Configuration Software, and test communication with the host system via Modbus.

Before installing the 3500/70 140471-01, ensure the 3500 Rack is properly grounded and the power supply (24V DC) is verified. Clean the rack slot and slide the module into place, securing it with retention brackets. Connect sensor cables to the designated terminal blocks, following the wiring diagram for RTD or thermocouple configurations. Configure channel parameters (e.g., sensor type, scaling, alarm thresholds) using Bently Nevada’s 3500 Configuration Software, and test communication with the host system via Modbus.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks should include verifying LED status indicators, tightening cable connections, and cleaning the module’s surface to prevent dust accumulation that could affect heat dissipation.

- Calibration: Annually calibrate the module using a certified temperature source to ensure measurement accuracy. Reference the user manual for step-by-step procedures.

- Firmware Updates: Periodically update the module’s firmware to access new features or bug fixes, ensuring compatibility with the latest software tools.

- Spare Parts Management: Maintain a spare 3500/70 140471-01 in inventory, pre-configured with identical settings, to minimize downtime in case of module failure. Leverage our global supply chain for rapid replacement of discontinued or urgent components.

3500/70 140471-01

Product Guarantee: BENTLY 3500/70 140471-01

Our company provides a 12-month quality warranty for the BENTLY 3500/70 140471-01 temperature monitoring module, covering non-human-induced hardware defects. During the warranty period, we will replace any module experiencing issues such as inaccurate readings, communication failures, or power supply faults at no additional cost. For discontinued models or urgent repair needs, our extensive inventory and global logistics network ensure prompt delivery of spare parts, minimizing disruptions to your industrial operations.

With 17 years of expertise in industrial control distribution, we are committed to delivering reliable, high-quality solutions that enhance machinery reliability and operational efficiency. The 3500/70 140471-01 exemplifies our dedication to providing robust, innovative components for critical applications. Contact us today to discuss how this module can strengthen your predictive maintenance strategy and support continuous, safe operations.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for Bently Nevada’s official technical documentation. Always refer to the manufacturer’s guidelines for detailed installation, operation, and safety instructions.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

BENTLY 3500/54 133396-01 Thermoelectric couple

BENTLY 3500/32 125720-01 Double-action switch

BENTLY 3500/45 176449-04 S100

BENTLY 3500/65 145988-02 I/O

BENTLY 330876-03-50-00-00 S200

BENTLY 3500/92 136180-01 Double output

BENTLY 3500/15 114M5330-01 Expansion module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: