Description

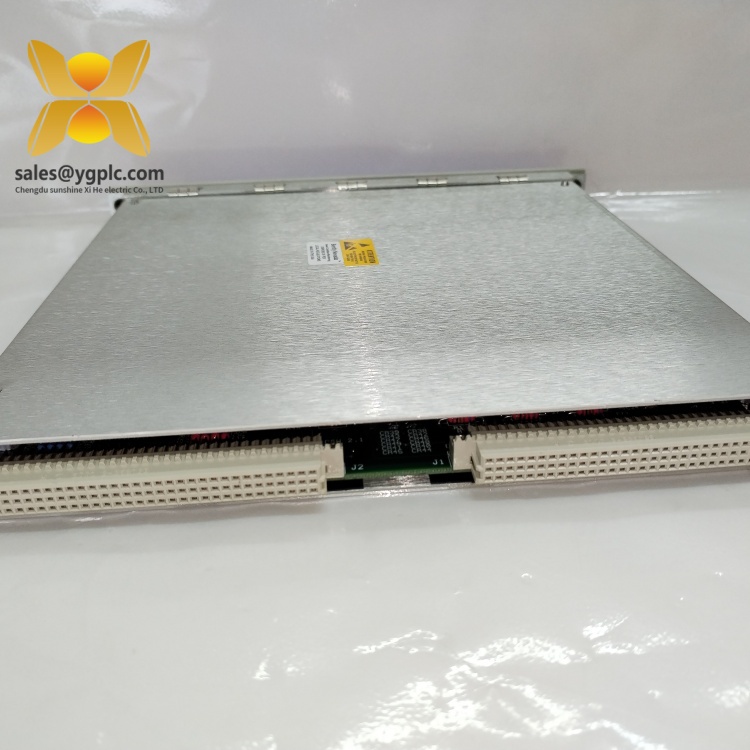

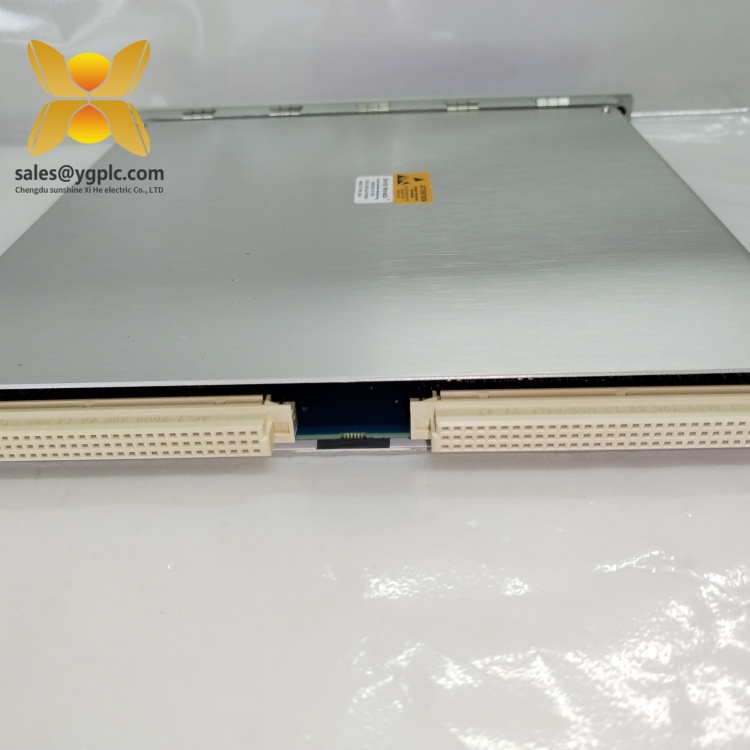

BENTLY 3500/62 Dual Channel Acceleration/Velocity Monitoring Module

Product Overview

The BENTLY 3500/62 is a high-precision Dual Channel Acceleration/Velocity Monitoring Module designed as a core component of Bently Nevada’s 3500 Series Machinery Protection System. Engineered to monitor vibration parameters in critical rotating equipment, this module converts acceleration and velocity signals from piezoelectric sensors into actionable data for predictive maintenance. As part of the 3500 Series, the 3500/62 supports seamless integration with other 3500 modules (e.g., proximity probes, keyphasor units), delivering comprehensive machinery health analysis in industries such as oil & gas, power generation, and manufacturing.

Featuring a rugged industrial design, the BENTLY 3500/62 processes vibration data from two independent channels, each supporting acceleration (0–50 g) or velocity (0–100 in/sec) measurements with ±1% accuracy. Its advanced signal conditioning circuitry includes anti-aliasing filters and built-in diagnostics, enabling real-time detection of mechanical issues like imbalance, misalignment, or bearing wear. The module’s hot-swappable architecture allows replacement without system shutdown, while its wide operating temperature range (-40°C to +70°C) ensures reliability in harsh environments. Compatibility with API 670 and IEC 61511 standards makes the 3500/62 indispensable for safety-critical applications where equipment failure risks operational downtime or hazards.

In automation ecosystems, the 3500/62 serves as the backbone of vibration monitoring systems, feeding real-time data to supervisory control layers for trend analysis and alarm activation. Its dual-channel design supports redundant sensor configurations, eliminating single points of failure. By providing precise vibration insights, the 3500/62 empowers maintenance teams to schedule proactive repairs, extend equipment lifespan, and optimize operational efficiency in mission-critical setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/62 |

| Manufacturer | Bently Nevada |

| Product Type | Vibration Monitoring Module |

| Channels | 2 independent channels |

| Measurement Types | Acceleration (0–50 g), velocity (0–100 in/sec) |

| Frequency Response | 10–10,000 Hz |

| Output Signal | 4–20 mA, 0–10 V DC |

| Resolution | 16-bit |

| Physical Dimensions | 10.16 cm (H) × 16.51 cm (W) × 22.86 cm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +70°C |

| Mounting | Rack-mounted in 3500 Series enclosure |

| Certifications | API 670, IEC 61511, CE, UL |

Key Features and Advantages

Dual-Channel Redundancy: The 3500/62 processes data from two independent vibration sensors, enabling redundant monitoring and fault tolerance. This design ensures continuous operation even if one channel fails, critical for maintaining safety in high-risk industrial environments.

Multi-Parameter Measurement: Supporting both acceleration and velocity measurements, the module adapts to diverse machinery types, from high-speed turbines to low-frequency reciprocating engines. This versatility reduces the need for multiple specialized modules, optimizing hardware costs.

High-Accuracy Signal Conditioning: With ±1% measurement accuracy and 16-bit resolution, the 3500/62 captures subtle vibration changes, enabling early detection of developing faults. Anti-aliasing filters eliminate signal distortion, ensuring reliable data for trend analysis.

Hot-Swap Capability: The module can be replaced without powering down the system, minimizing downtime during maintenance. This feature is essential for 24/7 operations where unplanned outages impact productivity.

Comprehensive Diagnostics: Built-in self-test functions monitor sensor health, signal integrity, and module performance, providing real-time alerts via LED indicators and digital outputs. This proactive diagnostics reduce mean time to repair (MTTR) and enhance system availability.

Rugged Environmental Design: Engineered to withstand extreme temperatures, vibration, and electromagnetic interference, the 3500/62 ensures reliable performance in offshore platforms, refineries, and other harsh industrial settings.

Application Areas

The BENTLY 3500/62 is critical for vibration monitoring in industries reliant on rotating equipment:

- Oil & Gas: Monitors compressors, pumps, and turbines in refineries, pipelines, and offshore rigs to detect imbalance or bearing wear, preventing costly production interruptions.

- Power Generation: Installed on steam turbines, generators, and auxiliary systems in thermal and nuclear plants to maintain grid stability and optimize energy output.

- Manufacturing: Used in high-speed motors, fans, and conveyor systems in automotive, chemical, and food processing facilities to ensure production continuity and product quality.

- Mining: Deployed on crushers, mills, and ventilation systems to monitor equipment health in harsh mining environments, reducing maintenance costs and downtime.

Specific applications include:

- Turbine Health Monitoring: Analyzes vibration patterns in steam turbines to identify early signs of blade damage or shaft misalignment.

- Compressor Protection: Monitors axial and radial vibrations in natural gas compressors to prevent catastrophic failures.

- Predictive Maintenance: Provides real-time vibration data for condition-based maintenance strategies, reducing unplanned repairs and extending equipment life.

Related Products

- 3500/42M Vibration Monitor: A single-channel variant for basic vibration analysis, compatible with the 3500/62 in multi-probe setups.

- 3500/22M Keyphasor Module: Supplies rotational reference signals to the 3500/62 for phase-locked vibration analysis.

- 3500/15 Power Supply Module: Ensures redundant power for the 3500/62 and other 3500 Series modules.

- 3300 XL Proximity Probe System: Works alongside the 3500/62 to measure shaft displacement in combination with vibration data.

- 3500/32M Relay Module: Triggers alarms or shutdowns based on vibration thresholds from the 3500/62.

- 3500/92 Communication Gateway: Enables remote access to 3500/62 data via Ethernet for integration with SCADA systems.

Installation and Maintenance

Pre-installation Preparations:

Before installing the BENTLY 3500/62, ensure the 3500 Series rack is properly grounded and ventilated. Verify sensor compatibility (piezoelectric accelerometers or velocity transducers) and route shielded cables away from high-voltage lines to minimize interference. Mount the module in the rack using provided hardware, connecting power and sensor inputs per Bently Nevada’s wiring guidelines. Configure channel parameters (measurement type, alarm thresholds) using the 3500 Series configuration software to match machinery requirements.

Before installing the BENTLY 3500/62, ensure the 3500 Series rack is properly grounded and ventilated. Verify sensor compatibility (piezoelectric accelerometers or velocity transducers) and route shielded cables away from high-voltage lines to minimize interference. Mount the module in the rack using provided hardware, connecting power and sensor inputs per Bently Nevada’s wiring guidelines. Configure channel parameters (measurement type, alarm thresholds) using the 3500 Series configuration software to match machinery requirements.

Maintenance Suggestions:

- Routine Checks: Quarterly visual inspections of LED indicators to verify module health and sensor connectivity. Use diagnostic software to review vibration trends and ensure measurements fall within normal ranges.

- Calibration: Annually calibrate the 3500/62 using a vibration shaker table to maintain measurement accuracy. Document calibration results for compliance and traceability.

- Environmental Management: Clean module vents monthly to prevent dust accumulation, especially in dusty environments. Ensure the control room temperature (20–25°C) and humidity (40–60%) remain within optimal ranges.

- Spare Parts Management: Store spare 3500/62 modules in static-free packaging at room temperature, testing them annually to ensure functionality for quick replacement during failures.

Product Guarantee

Our company provides a 12-month quality warranty for the BENTLY 3500/62, covering hardware defects under normal use. In the event of performance issues—such as signal inaccuracies or module failures—we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the 3500/62 and related spares. Our technical support team assists with installation, calibration, and troubleshooting, ensuring reliable vibration monitoring to safeguard your industrial systems.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

Bently 135031-01 Digital output module

Bently 3500/44M 140734-03 Control system power supply

Bently 3500/54 133396-01 Pressure transmitter

BENTLY 3500/92 136180-01 Main frame

BENTLY 3500/15 114M5330-01 Expansion rack

BENTLY 3500/77M 176449-07 Network communication module

Bently 3500/44M 140734-03 Control system power supply

Bently 3500/54 133396-01 Pressure transmitter

BENTLY 3500/92 136180-01 Main frame

BENTLY 3500/15 114M5330-01 Expansion rack

BENTLY 3500/77M 176449-07 Network communication module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: