Description

I’ll provide a detailed product description for the Bently 3500/44M 140734-03, covering its overview, technical specs, features, applications, related products, installation & maintenance, and product guarantees.

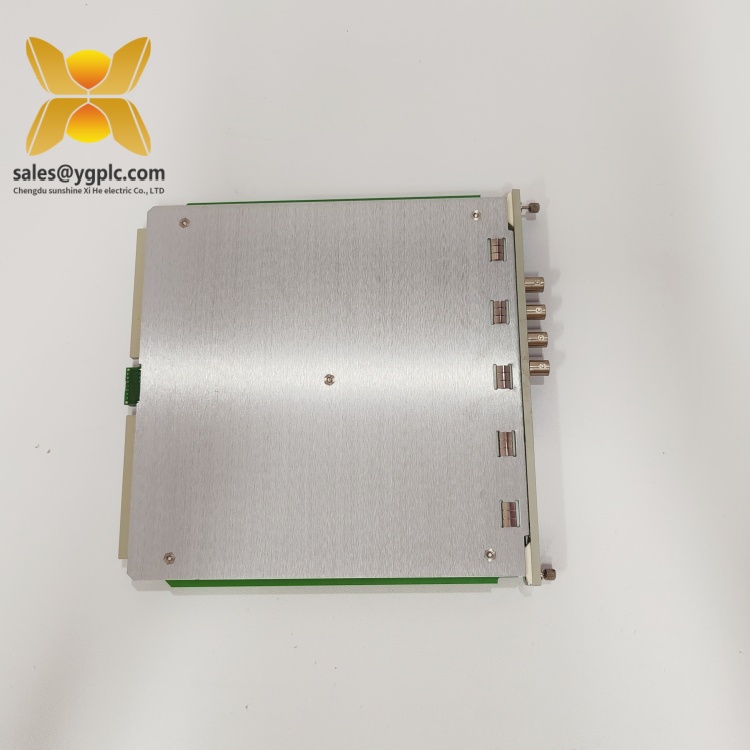

Product Overview:Bently 3500/44M 140734-03

The Bently 3500/44M 140734-03 is a high – performance vibration monitor module that plays a crucial role in the Bently 3500 series, which is renowned for its comprehensive machinery protection and monitoring capabilities. This module is designed to provide accurate and reliable vibration monitoring in various industrial automation systems, especially those involving rotating and reciprocating machinery.

As part of the Bently Nevada’s advanced machinery protection platform, the 3500/44M is engineered to meet the strict requirements of industries such as power generation, oil and gas, petrochemicals, and manufacturing. It offers multiple channels for monitoring vibration signals, allowing for a detailed assessment of the machinery’s health. By precisely measuring vibration levels, the module enables early detection of potential mechanical problems, such as unbalance, misalignment, and bearing wear. This not only helps prevent costly equipment failures but also improves the overall efficiency and reliability of the industrial processes.

The 3500/44M 140734 – 03 is highly integrated and features advanced signal processing algorithms. It can interface with other components within the 3500 system, creating a cohesive and intelligent monitoring solution. With its ability to communicate digital and analog data, it ensures seamless integration into existing control and monitoring infrastructure, making it an essential component for maintaining the integrity of industrial machinery in complex automation setups.

Technical Specifications:Bently 3500/44M 140734-03

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/44M 140734-03 |

| Manufacturer | Bently Nevada |

| Product Type | Vibration Monitor Module |

| Number of Channels | Multiple (suitable for comprehensive vibration monitoring) |

| Input Signal Range | Compatible with a wide range of vibration sensor signals |

| Output Signal | 4 – 20 mA proportional values for each channel (for easy connection to control systems) |

| Communication Protocol | Supports standard industrial communication protocols for seamless integration |

| Power Supply Requirements | Specific voltage and current requirements to ensure stable operation |

| Physical Dimensions | Compact size designed for easy installation in control cabinets |

| Operating Temperature Range | Able to function within a wide temperature range, suitable for harsh industrial environments |

| Vibration Measurement Accuracy | High – precision measurement to detect even minor vibrations |

| Mounting Method | Designed for convenient mounting within the 3500 system framework |

Bently 3500/44M 140734-03

Main Features and Advantages:Bently 3500/44M 140734-03

The Bently 3500/44M 140734-03 offers several key features that set it apart in the market. Its high – accuracy vibration measurement is a standout feature. Thanks to advanced sensor technology and signal processing algorithms, it can detect the slightest vibrations, providing operators with detailed and reliable data about the machinery’s condition. This level of precision is essential for early fault detection, as it allows for the identification of potential problems before they escalate into major breakdowns.

The module’s multiple – channel design is another significant advantage. With the ability to monitor vibration from different points on the machinery simultaneously, it gives a more comprehensive view of the equipment’s health. This is particularly useful in complex machinery setups where vibrations can occur in multiple locations, and a single – channel monitor may not be sufficient to capture all relevant data.

In terms of communication, the 3500/44M is highly versatile. It supports both digital and analog communication, which means it can easily interface with a wide variety of control systems and other monitoring devices. This compatibility makes it a flexible choice for industrial plants, as it can be integrated into existing infrastructure without major re – engineering efforts.

Moreover, the 3500/44M 140734-03 is designed with reliability in mind. It is built to withstand harsh industrial environments, including extreme temperatures, high humidity, and electromagnetic interference. This rugged construction ensures continuous operation, minimizing downtime and maximizing the productivity of the industrial processes it serves.

Application Areas:Bently 3500/44M 140734-03

The Bently 3500/44M 140734-03 has a wide range of applications across various industries. In the power generation sector, it is used to monitor the vibration of turbines, generators, and other rotating equipment. By continuously monitoring vibration levels, power plant operators can ensure the smooth operation of these critical components, prevent unexpected outages, and optimize energy production.

In the oil and gas industry, the module plays a vital role in monitoring pumps, compressors, and motors. These machines are often operating in harsh and remote environments, and any failure can lead to significant production losses. The 3500/44M helps in early detection of mechanical issues, allowing for timely maintenance and reducing the risk of costly breakdowns.

Manufacturing plants also benefit greatly from the 3500/44M. It can be used to monitor the vibration of manufacturing equipment such as conveyors, motors, and rotating shafts. By maintaining optimal vibration levels, manufacturers can improve product quality, reduce scrap rates, and extend the lifespan of their equipment.

In petrochemical facilities, where safety and continuous operation are of utmost importance, the 3500/44M is used to monitor the vibration of large – scale processing equipment. Early detection of vibration – related problems can prevent catastrophic failures, ensuring the safety of personnel and the environment.

Bently 3500/44M 140734-03

Related Products:Bently 3500/44M 140734-03

- Bently 3500/42M: Similar to the 3500/44M, it is a vibration monitor module in the 3500 series. However, it may have differences in the number of channels or specific signal processing capabilities. The 3500/42M also provides 4 – 20 mA proportional values for each channel, but the 3500/44M might offer enhanced features in certain areas, such as more advanced filtering options.

- Bently 3500/05 Frame: This is the frame in which the 3500/44M module is installed. The frame provides the physical structure and electrical connections for the module and other components within the 3500 system. A proper frame is essential for the stable operation of the 3500/44M module.

- Bently 3500/15 Power Supply: It supplies the necessary power to the 3500/44M module and other components in the 3500 system. A reliable power supply is crucial for the continuous and accurate operation of the vibration monitor module.

- Bently 3500/22 Rack Interface Module: Facilitates communication and interaction between the 3500/44M module and other modules in the rack. It helps in coordinating data transfer and control signals within the 3500 system.

- Bently 3500/92 Communication Gateway Module: Enables the 3500/44M – equipped 3500 system to communicate with external systems. It can transfer vibration data and other relevant information to control rooms, remote monitoring stations, or other industrial networks.

Bently 3500/44M 140734-03

Installation and Maintenance:Bently 3500/44M 140734-03

Installation Preparations: Before installing the Bently 3500/44M 140734-03 module, ensure that the 3500 system framework, such as the 3500/05 frame, is properly prepared. Check the power supply, making sure the 3500/15 power supply is functioning correctly and can provide the required power to the module. Verify that all the necessary communication and connection interfaces are clean and free from any damage. Also, ensure that the environment where the module will be installed meets the specified operating conditions, such as temperature and humidity requirements.

Maintenance Recommendations: Regularly inspect the 3500/44M module for any signs of physical damage, such as cracks or loose connections. Check the vibration sensor connections to ensure they are secure. Periodically calibrate the module to maintain its high – accuracy vibration measurement capabilities. Monitor the communication channels to ensure seamless data transfer. In case of any abnormal vibration readings or communication issues, refer to the product manual or contact our technical support team for assistance. Keep the module clean and free from dust and debris, as these can affect its performance over time.

Bently 3500/44M 140734-03

Product Guarantee:Bently 3500/44M 140734-03

Our company provides a one – year quality warranty service for the Bently 3500/44M 140734-03 product, covering hardware failures caused by non – human factors. During the warranty period, if the product exhibits abnormal performance or functional failures, we will provide replacement services. In addition, for discontinued models or urgent needs, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, helping to ensure the continuous and stable operation of industrial systems.

If you need more information about the Bently 3500/44M 140734-03, like its compatibility with specific machinery or more in – depth technical details, feel free to let me know.

TRICONEX AI3351 Digital 24VDC output module

ABB PM633 Acquisition card

ABB REF542PLUS Gas turbine card

CONVERTEAM P110-6052 DC/DC

ABB PPC905AE101 3BHE014070R0101 Analog output module

ABB DSPU131 3BSE000355R1 display

ABB GFD233A103 3BHE022294R0103 Relay output

FOXBORO P0926GV FBM231 Optical isolation module

Hirschmann MM3-2FXM2-2TX1 probe

Hirschmann MM20-Z6Z6Z6Z6SAHH Tachometer sensor

TRICONEX DO2401 7400209-030 rack

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: