Description

BENTLY 3500/05 Product Specification

Product Overview

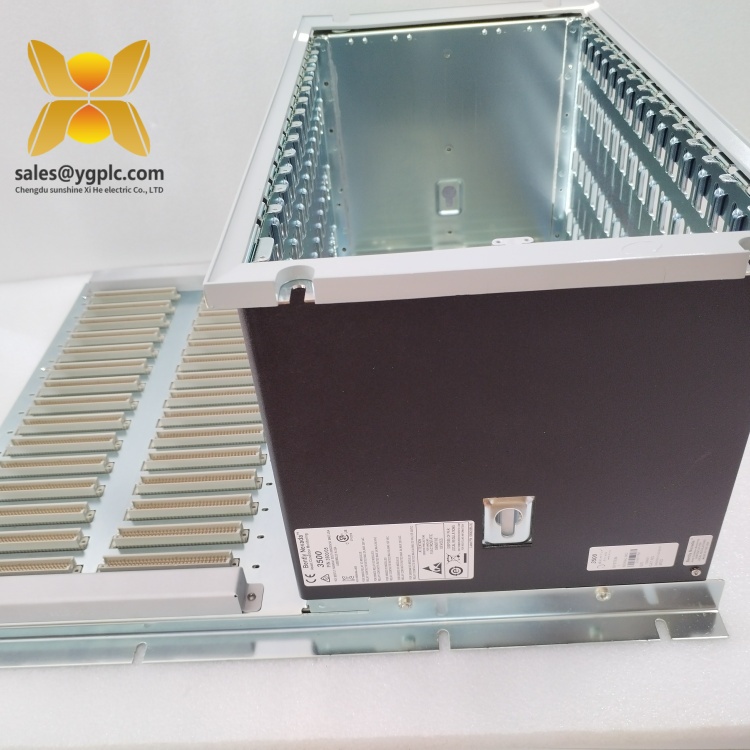

The BENTLY 3500/05 is a critical rack interface module designed for BENTLY’s 3500 Series Machinery Protection System, serving as the central communication hub for industrial automation setups. Engineered to enable seamless data exchange between rack-mounted modules and higher-level control systems, the BENTLY 3500/05 plays a pivotal role in monitoring and protecting rotating machinery across industries such as oil and gas, power generation, and manufacturing. As part of the 3500 Series, this module ensures reliable connectivity and real-time data transmission, forming the backbone of comprehensive machinery health management solutions.

The BENTLY 3500/05 integrates dual communication ports (RS-485 and Ethernet) to support both legacy and modern industrial networks, enabling compatibility with PLCs, HMIs, and supervisory control systems. Its modular design allows for easy integration into 19″ racks, with a compact form factor (210 mm × 150 mm × 100 mm) and lightweight construction (1.8 kg) that simplifies installation and maintenance. The module’s rugged IP23-rated enclosure and conformal-coated PCBs protect against dust, moisture, and electromagnetic interference (EMI), ensuring reliable operation in harsh industrial environments.

In automation systems, the BENTLY 3500/05 acts as a gateway, translating data from vibration monitors, temperature sensors, and other 3500 Series modules into a unified communication protocol. Its high-speed data processing capability (up to 10 Mbps) ensures real-time transmission of critical machinery health data, enabling predictive maintenance and reducing unplanned downtime. By combining robust hardware with flexible configuration options, the BENTLY 3500/05 empowers engineers to build scalable, reliable protection systems for mission-critical equipment.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 3500/05 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Rack Interface Module |

| Communication Ports | 2 × RS-485, 1 × 10/100BaseT Ethernet |

| Data Transfer Rate | Up to 10 Mbps |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 210 mm (W) × 150 mm (H) × 100 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Enclosure Protection | IP23 |

| Certifications | CE, UL, ISO 9001 |

Main Features and Advantages

Dual-Protocol Connectivity: The BENTLY 3500/05 supports both RS-485 and Ethernet communication, enabling seamless integration with legacy equipment and modern industrial networks. This dual capability eliminates the need for additional gateways, reducing system complexity and costs.

High-Speed Data Processing: With a data transfer rate of up to 10 Mbps, the module ensures real-time transmission of machinery health data, allowing engineers to respond promptly to critical events. Its built-in buffer memory stores temporary data during network interruptions, preventing information loss.

Rugged Industrial Design: Constructed with an IP23-rated enclosure, the BENTLY 3500/05 withstands harsh environmental conditions, including high temperatures, humidity, and vibration. The conformal-coated PCBs protect against dust and corrosive elements, enhancing reliability in offshore platforms and manufacturing plants.

Modular System Integration: As the central interface for the 3500 Series, the module supports up to 19 additional modules per rack, enabling scalable configurations, from small setups to large industrial systems. Its hot-swappable design allows maintenance without powering down the rack, minimizing downtime.

Advanced Diagnostic Tools: The module provides real-time status updates via front-panel LEDs and supports remote diagnostics through BENTLY’s proprietary software. This proactive approach to maintenance helps identify connectivity issues before they escalate, improving system availability.

Application Areas

The BENTLY 3500/05 is essential in industries where reliable machinery monitoring is critical:

-

Oil and Gas:

- Connects vibration monitors and emergency shutdown systems (ESD) in refineries and offshore platforms, ensuring safe and efficient operations.

- Transmits real-time data from pipeline compressors to central control rooms, enabling proactive maintenance and flow optimization.

-

Power Generation:

- Integrates with turbine protection systems in power plants, transmitting vibration and temperature data to SCADA systems for real-time analysis.

- Supports remote monitoring of generators, enabling predictive maintenance to prevent costly outages.

-

Manufacturing:

- Connects high-speed production line machinery (e.g., robotic arms, conveyor drives) to PLCs, ensuring precise control and quality assurance.

- Translates data from vibration sensors in automotive plants to central systems, reducing unplanned downtime.

-

Water/Wastewater Treatment:

- Links pump station sensors to SCADA systems, enabling remote monitoring of water flow and quality.

- Transmits data from treatment plant equipment to facilitate scheduled maintenance and regulatory compliance.

Related Products

- BENTLY 3500/15 125840-02: A power input module that supplies stable 24 VDC to the BENTLY 3500/05 and other 3500 Series components.

- BENTLY 3500/22M 146031-01: A vibration monitoring module that works with the BENTLY 3500/05 to transmit real-time vibration data.

- BENTLY 3500/32 129407-01: A speed/torque monitor that pairs with the BENTLY 3500/05 to correlate rotational speed with vibration analysis.

- BENTLY 3500/42 129408-01: A temperature monitor module that sends thermal data through the BENTLY 3500/05 for comprehensive machinery health reports.

- BENTLY 3500/92 129410-01: A communication gateway that extends the BENTLY 3500/05’s capabilities to Ethernet/IP networks for cloud-based monitoring.

Installation and Maintenance

Pre-installation Preparation:

Before installing the BENTLY 3500/05, ensure the following:

Before installing the BENTLY 3500/05, ensure the following:

- Verify the power supply is 24 VDC ±10% and the control rack is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability.

- Configure communication parameters (baud rate, IP address) via BENTLY’s software to match the target network. Ensure RS-485 and Ethernet cables are shielded to minimize EMI.

- Mount the module in a 19″ rack with at least 50 mm of clearance for airflow, securing it with the provided brackets to prevent vibration-induced displacement.

Maintenance Recommendations:

- Routine Inspections: Monthly checks of front-panel LEDs (green for normal operation, red for faults) and cleaning dust from ventilation slots. Use a soft brush to avoid damaging internal components.

- Communication Testing: Quarterly verification of RS-485 and Ethernet connectivity using BENTLY’s diagnostic tools. Perform loopback tests to ensure signal integrity.

- Firmware Updates: Periodically update the module’s firmware to access new features and security patches, particularly when integrating with newer system versions.

- Environmental Monitoring: Regularly assess ambient temperature and humidity levels to ensure they remain within the module’s operational range, especially in harsh environments.

Product Warranty

Our company provides a one-year quality warranty for the BENTLY 3500/05, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits communication errors or functional defects. For discontinued models like the BENTLY 3500/05, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including configuration assistance and repair services, to maintain your system’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data from BENTLY’s official specifications and industry applications. For detailed installation guidelines, refer to the BENTLY 3500/05 user manual or contact our technical support team.

BENTLY 3500/15 127610-01 Double-action switch

BENTLY 3500/22M 138607-01 DC/DC

BENTLY 3500/22M 146031-01 Analog output module

BENTLY 135489-02 Input module

BENTLY 3500-20 AI/AO/DI/DO module

BENTLY 135031-01 Servo valve

BENTLY 3500/92 136180-01 Servo motor,

BENTLY 3500/92 136188-01 Industrial keyboard

BENTLY 3500/94 145988-01 encoder

BENTLY 3500/94 147663-01 regulator

BENTLY 3500/44M 140734-03 Digital quantity

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: