Description

BENTLY 3500/05-02-04-00-00-00 Product Specification

Product Overview

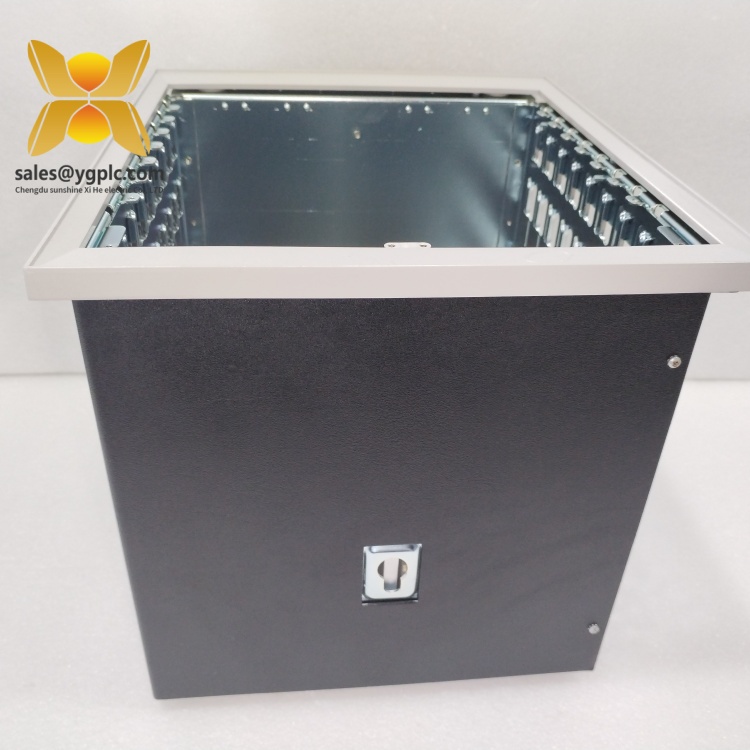

The BENTLY 3500/05-02-04-00-00-00 is a 19-inch rack-mounted chassis designed for BENTLY’s 3500 Series Machinery Protection System. Engineered to house and integrate various monitoring modules, this chassis serves as the foundational framework for building comprehensive machinery health management systems. The BENTLY 3500/05-02-04-00-00-00 supports up to 19 module slots, enabling seamless integration of vibration monitors, temperature controllers, and communication gateways in industrial automation setups. As a key component of the 3500 Series, it provides mechanical and electrical connectivity for critical monitoring functions across industries such as oil and gas, power generation, and manufacturing.

Constructed with a rugged steel frame, the BENTLY 3500/05-02-04-00-00-00 ensures reliable performance in harsh environments. Its modular design allows for flexible configuration, with 2U height and 19-inch width compatible with standard control racks. The chassis integrates a backplane for power distribution and data communication, supporting hot-swappable module installation without system shutdowns. With pre-drilled mounting holes and removable side panels, the BENTLY 3500/05-02-04-00-00-00 simplifies installation and maintenance in industrial control rooms or field cabinets.

In automation systems, the BENTLY 3500/05-02-04-00-00-00 acts as the physical and electrical backbone of the 3500 Series, enabling real-time monitoring of rotating machinery. Its redundant power supply capability (supports two power modules) enhances system reliability, while the integrated CEX bus ensures high-speed data transfer between modules. By providing a stable platform for monitoring components, the chassis plays a critical role in enabling predictive maintenance strategies that minimize downtime and extend equipment lifespan.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 3500/05-02-04-00-00-00 |

| Manufacturer | BENTLY NEVADA |

| Product Type | 19-inch Rack-mounted Chassis |

| Module Slots | 19 slots (16 user slots + 3 dedicated slots) |

| Physical Dimensions | 482.6 mm (W) × 88.9 mm (H) × 355.6 mm (D) (19-inch, 2U height) |

| Weight | 7.5 kg |

| Power Supply | Supports two 24 VDC power modules (sold separately) |

| Backplane Communication | CEX bus (high-speed data transfer) |

| Mounting | 19-inch rack-mounted (flange or rack ears included) |

| Operating Temperature | 0°C to +55°C |

| Humidity | 5–95% non-condensing |

| Shock Resistance | 50 g (11 ms, half sine wave) |

| Vibration Resistance | 2 g (5–500 Hz) |

| Certifications | CE, UL, CSA |

Main Features and Advantages

Modular Expandability: The BENTLY 3500/05-02-04-00-00-00 supports up to 19 modules, allowing users to build custom monitoring systems for specific machinery needs. This flexibility is ideal for scaling from small setups to large industrial complexes, with the ability to add vibration monitors, speed probes, or communication gateways as required.

Rugged Industrial Design: Constructed with heavy-gauge steel, the chassis withstands harsh industrial environments, including vibration (2 g), shock (50 g), and temperature fluctuations (0°C to +55°C). The powder-coated finish resists corrosion, making it suitable for offshore platforms, power plants, and manufacturing facilities.

Redundant Power Capability: With support for two 24 VDC power modules (e.g., BENTLY 3500/15), the chassis ensures uninterrupted operation via power redundancy. This feature is critical for mission-critical applications where downtime is not an option.

Hot-Swap Functionality: Modules can be inserted or removed while the chassis is powered, enabling maintenance without system shutdowns. This reduces downtime and allows for component replacement during scheduled maintenance or unexpected failures.

Integrated Data Communication: The CEX backplane enables high-speed data transfer between modules, ensuring real-time communication for synchronized monitoring. This integration is essential for complex systems requiring rapid data analysis, such as turbine or compressor monitoring.

Application Areas

The BENTLY 3500/05-02-04-00-00-00 is essential in industries where machinery reliability is critical:

-

Oil and Gas:

- Houses vibration and temperature monitoring modules for compressors, pumps, and turbines in refineries and offshore platforms.

- Enables real-time monitoring of pipeline pumps to prevent failures and ensure continuous fluid transfer.

-

Power Generation:

- Supports monitoring systems for steam and gas turbines, generators, and auxiliary equipment in power plants.

- Integrates with SCADA systems to provide real-time data on rotor dynamics and bearing health, optimizing energy production.

-

Manufacturing:

- Manages vibration monitoring for high-speed production lines, robotic arms, and conveyor systems in automotive and pharmaceutical plants.

- Enables predictive maintenance of motors and drives to minimize production losses.

-

Water/Wastewater Treatment:

- Houses modules for monitoring pumps and treatment plant equipment, ensuring consistent water quality and flow.

- Supports remote monitoring of distributed water systems via communication modules integrated into the chassis.

Related Products

- BENTLY 3500/15 125840-02: A 24 VDC power module compatible with the BENTLY 3500/05-02-04-00-00-00, providing redundant power supply.

- BENTLY 3500/22M 146031-01: A vibration monitoring module that installs in the chassis to measure shaft vibration and displacement.

- BENTLY 3500/32 129407-01: A speed/torque monitor for integrating rotational speed data with vibration analysis.

- BENTLY 3500/42 129408-01: A temperature monitoring module for capturing thermal data from critical components.

- BENTLY 3500/92 129410-01: A communication gateway module for connecting the chassis to Ethernet/IP networks.

- BENTLY 3500/95 129411-01: A redundant power supply module enhancing system availability in the BENTLY 3500/05-02-04-00-00-00.

Installation and Maintenance

Pre-installation Preparation:

Before installing the BENTLY 3500/05-02-04-00-00-00, ensure the following:

Before installing the BENTLY 3500/05-02-04-00-00-00, ensure the following:

- Verify the control rack meets 19-inch standards and has sufficient depth (minimum 355.6 mm) to accommodate the chassis. Use the provided rack ears or flange mounts to secure the chassis, ensuring proper grounding to prevent electrostatic discharge (ESD).

- Install compatible power modules (e.g., BENTLY 3500/15) in the dedicated slots, connecting them to a stable 24 VDC power source. Ensure power cables are routed separately from data cables to minimize interference.

- Plan module placement based on functionality, leaving space for future expansions. Use BENTLY’s configuration software to map module addresses and define communication parameters before powering on the system.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks for loose connections, damaged cables, or overheating. Use a non-conductive tool to tighten mounting screws and ensure modules are seated correctly.

- Environmental Monitoring: Regularly assess ambient temperature and humidity levels around the chassis, ensuring they stay within 0°C to +55°C and 5–95% non-condensing. Clean dust from ventilation slots quarterly to maintain optimal cooling.

- Redundancy Testing: Biannually test power module redundancy by simulating a power failure to ensure failover functionality. Verify that the CEX bus maintains data communication during power transitions.

- Firmware Management: Periodically update module firmware via BENTLY’s software to access new features and security patches, particularly for communication modules integrated into the chassis.

Product Warranty

Our company provides a one-year quality warranty for the BENTLY 3500/05-02-04-00-00-00, covering hardware defects due to non-human factors. During the warranty period, we will replace any chassis that exhibits structural damage or electrical failure. For discontinued models like the BENTLY 3500/05-02-04-00-00-00, our global inventory ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including chassis refurbishment and component replacement, to maintain your system’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on BENTLY NEVADA’s technical specifications and industry applications. For detailed installation guides, refer to the BENTLY 3500/05-02-04-00-00-00 user manual or contact our technical support team.

BENTLY 3500/92 136180-01 Servo motor,

BENTLY 3500/92 136188-01 Industrial keyboard

BENTLY 3500/94 145988-01 encoder

BENTLY 3500/94 147663-01 regulator

BENTLY 3500/44M 140734-03 Digital quantity

BENTLY 3500/22M 146031-01 Analog output module

BENTLY 135489-02 Input module

BENTLY 3500-20 AI/AO/DI/DO module

BENTLY 135031-01 Servo valve

BENTLY 3500/32 125712-01 display

BENTLY 3500/42M 176449-02 Relay output

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: