Description

BENTLY 3500/05-01-03-00-00-00 Rack Enclosure

Product Overview :BENTLY 3500/05-01-03-00-00-00

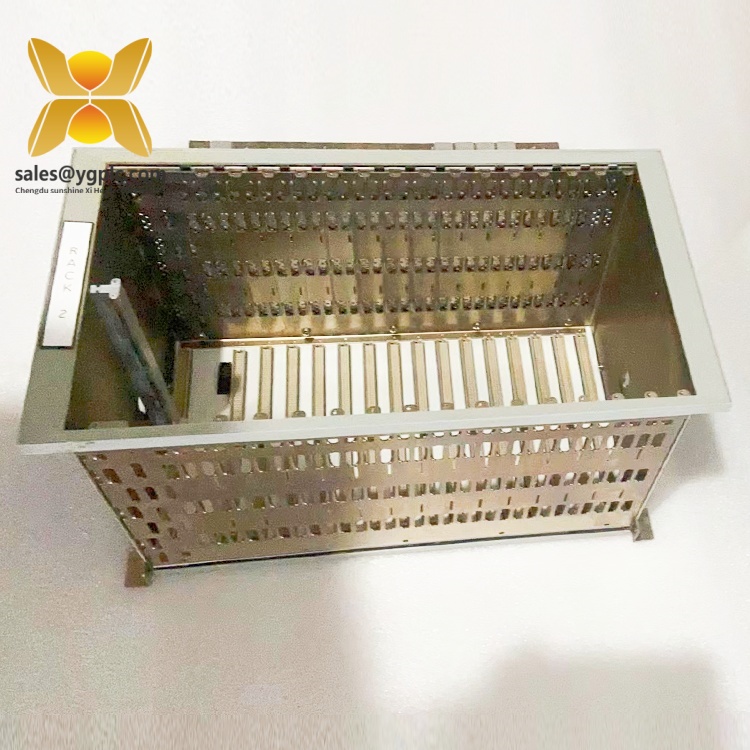

The BENTLY 3500/05-01-03-00-00-00 is a high-reliability Rack Enclosure designed as the foundational hardware platform for Bently Nevada’s 3500 Series machinery protection and condition monitoring systems. Engineered to house and integrate critical modules such as vibration monitors, communication gateways, and power supplies, this rack enclosure serves as the central hub for industrial automation systems in sectors like oil & gas, power generation, and manufacturing. The 3500/05-01-03-00-00-00 ensures seamless coordination between modules, providing a robust framework for real-time data acquisition, alarm processing, and system diagnostics, thereby enhancing the safety and operational efficiency of rotating equipment like turbines, compressors, and generators.

Constructed with a rugged steel frame and modular design, the BENTLY 3500/05-01-03-00-00-00 supports up to 19 modules in a 19-inch rack configuration, offering flexibility for scalable system expansions. Its integrated backplane provides reliable electrical connectivity and power distribution, while front-facing LED indicators enable quick visual diagnostics of module statuses. The enclosure’s design prioritizes thermal management, featuring forced-air cooling and optimized airflow pathways to maintain operational stability in high-temperature environments. As a core component of the 3500 Series, this rack enclosure simplifies installation and maintenance, reducing downtime and ensuring long-term reliability in mission-critical applications.

In industrial ecosystems, the 3500/05-01-03-00-00-00 plays a pivotal role in consolidating control and monitoring functionalities. It supports redundant power supplies and communication modules, enhancing system resilience against single points of failure. Whether deployed in standalone machinery protection systems or integrated with distributed control systems (DCS), this rack enclosure provides a standardized platform for data integration, enabling predictive maintenance strategies and compliance with industry standards like API 670. By combining structural integrity with advanced thermal and electrical design, the BENTLY 3500/05-01-03-00-00-00 sets a benchmark for reliability in industrial rack systems.

Technical Specifications :BENTLY 3500/05-01-03-00-00-00

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3500/05-01-03-00-00-00 |

| Manufacturer | Bently Nevada |

| Product Type | Rack Enclosure |

| Form Factor | 19-inch standard rack, 7U height |

| Module Capacity | Up to 19 modules (including power supplies and communication gateways) |

| Power Supply | Supports dual redundant 19.2–26.4 VDC power supplies (sold separately) |

| Physical Dimensions | 311 mm (H) × 483 mm (W) × 356 mm (D) |

| Weight | 12.7 kg |

| Operating Temperature | 0°C to +50°C (with derating above 40°C) |

| Mounting | Wall-mounted or free-standing via rack rails |

| Cooling | Forced-air cooling with replaceable air filters |

| Certifications | CE, API 670, ISO 10816 |

3500-05-01-03-00-00-00

Key Features and Advantages :BENTLY 3500/05-01-03-00-00-00

Modular Scalability: The 3500/05-01-03-00-00-00 accommodates up to 19 modules, allowing users to configure systems based on specific monitoring needs. This scalability is ideal for retrofitting existing equipment or expanding monitoring capabilities in growing industrial facilities.

Redundant Design: The enclosure supports dual redundant power supplies and communication modules (e.g., 3500/92), ensuring continuous operation during maintenance or component failure. This redundancy is critical for maintaining uptime in high-value assets like gas turbines or offshore compressors.

Thermal Management: Built-in fans and airflow channels maintain optimal operating temperatures, even in environments with ambient temperatures up to 50°C. Replaceable air filters prevent dust and particulate ingress, reducing the risk of component degradation.

Ease of Installation: The rack’s front-accessible design simplifies module insertion/removal and wiring, while labeled terminal blocks and standardized backplane connections reduce installation errors. Pre-drilled mounting holes facilitate quick integration into control panels or machinery rooms.

Comprehensive Diagnostics: Front-panel LED indicators for each module provide real-time status updates (e.g., power, communication, alarms), enabling rapid fault identification. This feature minimizes troubleshooting time and supports proactive maintenance strategies.

Industry Compliance: Designed to meet API 670 and ISO 10816 standards, the 3500/05-01-03-00-00-00 ensures compliance with machinery protection requirements in regulated industries, reducing audit risks and enhancing operational safety.

3500-05-01-03-00-00-00

Application Areas :BENTLY 3500/05-01-03-00-00-00

The BENTLY 3500/05-01-03-00-00-00 is essential for industries requiring robust machinery monitoring and control:

- Oil & Gas: Deployed in refineries, offshore platforms, and pipeline compressor stations to house 3500 Series modules monitoring turbine vibration, axial displacement, and bearing temperature.

- Power Generation: Used in thermal, hydro, and nuclear power plants to integrate protection systems for generators, steam turbines, and auxiliary machinery, ensuring grid stability and compliance with environmental regulations.

- Manufacturing: Supports condition monitoring of high-speed motors, pumps, and gearboxes in automotive, chemical, and pharmaceutical facilities, enabling predictive maintenance to avoid production line disruptions.

- Mining and Metals: Installed in processing plants to monitor crushers, mills, and conveyor systems, reducing downtime in mineral extraction and refining operations.

Specific applications include:

- Machinery Protection Systems (MPS): Houses vibration monitoring modules (e.g., 3500/42M) and relay modules (e.g., 3500/32M) to trigger alarms or shutdowns in response to critical faults.

- Predictive Maintenance Platforms: Integrates with data acquisition modules (e.g., 3500/22M) to collect and analyze machinery health data, supporting proactive maintenance schedules and reducing unplanned outages.

- Redundant Control Systems: Works with dual 3500/61C rack interface modules to ensure fault-tolerant communication with higher-level DCS or SCADA systems.

Related Products :BENTLY 3500/05-01-03-00-00-00

- 3500/15 Power Supply Module: Dual-redundant 24 VDC power supply for the 3500/05-01-03-00-00-00, ensuring uninterrupted operation during power fluctuations.

- 3500/22M Data Acquisition Module: Captures and processes vibration and process data for storage and analysis, compatible with the rack’s modular design.

- 3500/42M Proximitor Monitor: Four-channel vibration and axial displacement monitor that integrates into the rack, providing real-time machinery health insights.

- 3500/92 Communication Gateway: Enables integration of the 3500/05-01-03-00-00-00 with third-party systems via MODBUS, Profibus, or Ethernet/IP protocols.

- 3500/32M Relay Module: Provides alarm and shutdown outputs based on signals from other 3500 Series modules, enhancing safety and control capabilities.

- 3500/53 Speed/Torque Module: Measures rotational speed and torque, complementing vibration monitoring in comprehensive machinery diagnostics.

- 3500/08 Terminal Block Kit: Front-mounted terminal blocks for field wiring, simplifying connections to sensors and actuators.

- 3500/09 Rack Mounting Kit: Additional hardware for wall or floor mounting, ensuring stability in high-vibration environments.

3500-05-01-03-00-00-00

Installation and Maintenance :BENTLY 3500/05-01-03-00-00-00

Pre-installation Preparations:

Before installing the BENTLY 3500/05-01-03-00-00-00, ensure the installation site is well-ventilated and free from excessive dust or moisture. Verify the rack’s grounding compliance with local electrical codes and prepare redundant power supplies (e.g., 3500/15). Mount the rack securely using the provided hardware, leaving clear access to front and rear panels for wiring and maintenance. Install modules starting from the power supply slots, following Bently Nevada’s recommended cabling guidelines to minimize electromagnetic interference.

Before installing the BENTLY 3500/05-01-03-00-00-00, ensure the installation site is well-ventilated and free from excessive dust or moisture. Verify the rack’s grounding compliance with local electrical codes and prepare redundant power supplies (e.g., 3500/15). Mount the rack securely using the provided hardware, leaving clear access to front and rear panels for wiring and maintenance. Install modules starting from the power supply slots, following Bently Nevada’s recommended cabling guidelines to minimize electromagnetic interference.

Maintenance Suggestions:

- Routine Inspections: Monthly checks should include verifying fan operation, cleaning air filters, and ensuring all modules are securely seated. Use a soft brush or compressed air to remove dust from the enclosure’s vents and internal components.

- Component Testing: Quarterly tests of redundant power supplies and communication modules (e.g., 3500/92) ensure failover functionality operates correctly. Document test results for compliance and maintenance records.

- Firmware Updates: Periodically update module firmware using Bently Nevada’s 3500 Configuration Software to access new features and security patches, backing up configurations before updates.

- Spare Parts Management: Maintain a spare 3500/05-01-03-00-00-00 enclosure in a climate-controlled environment (temperature: 10–30°C, humidity: 20–80% RH) to facilitate rapid replacement in case of physical damage or component failure.

3500-05-01-03-00-00-00

Product Guarantee :BENTLY 3500/05-01-03-00-00-00

Our company provides a 12-month quality warranty for the BENTLY 3500/05-01-03-00-00-00, covering hardware defects under normal use. In the event of structural damage or functional failure, we offer prompt replacement services to minimize downtime. For discontinued or legacy models, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick turnaround for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering tailored solutions to maintain the reliability of your industrial monitoring systems.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

BENTLY 3500/77M 176449-07 modbus card

BENTLY 3500/54 133396-01 Power strip

BENTLY 3500/32 125720-01 Power source

BENTLY 3500/45 176449-04 base

BENTLY 3500/65 145988-02 exchange

BENTLY 330876-03-50-00-00 DI module

BENTLY 3500/22M 138607-01 AI card

BENTLY 3500/93 135785-02C Pulse encoder

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: