Description

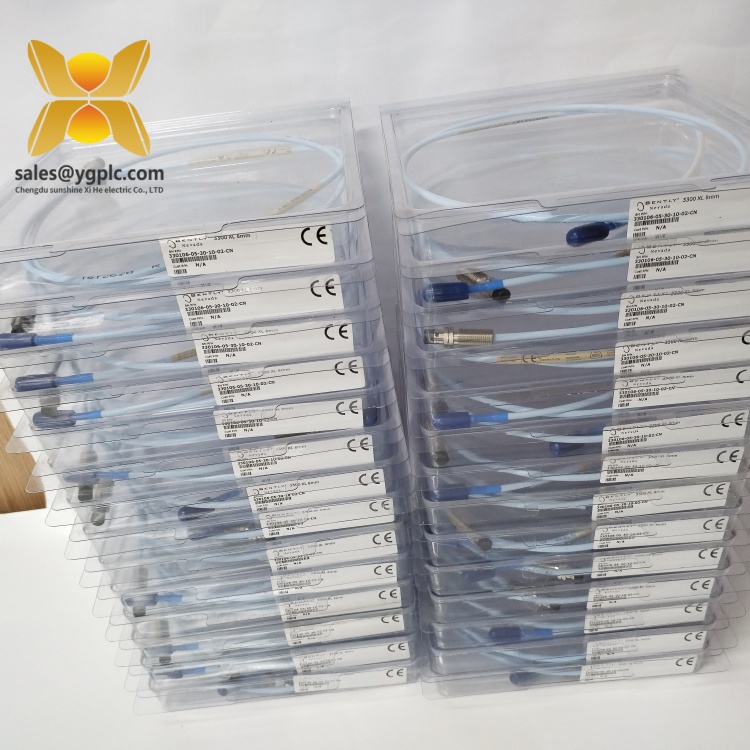

Bently Nevada 330130-080-00-CN – 8.0 m Extension Cable for 3300 XL 8 mm Proximity Transducer Systems

The Bently Nevada 330130-080-00-CN appears to be the 8.0 m extension cable used in the 3300 XL 8 mm proximity transducer system, linking the probe to the Proximitor sensor. In most cases, this length-matched cable is the go‑to choice for achieving factory-calibrated system accuracy without field compensations. It’s built for demanding environments where temperature, oil, and vibration are part of daily life.

Key Features

- 8.0 m calibrated length – Supports the 3300 XL 8 mm system’s length-sensitive calibration, typically avoiding additional adjustments.

- System compatibility – Designed for use with 3300 XL 8 mm probes (e.g., 330103/330104 series) and corresponding Proximitor sensors.

- Robust jacket – Chemically resistant, low-outgassing cable jacket that holds up in oil and process environments.

- Stable signal transfer – Maintains the integrity of the eddy-current probe signal over longer runs, which, from my experience, is key for reliable shaft vibration and position data.

- Non-armored, easy routing – Slim profile typically routes well in conduit and tight panels without the weight of armor.

- CN variant – Suffix suggests China-market packaging/documentation, while the underlying electrical compatibility remains the same.

Technical Specifications

| Brand / Model | Bently Nevada 330130-080-00-CN |

| Function | Extension cable for 3300 XL 8 mm proximity transducer systems |

| Cable Length | 8.0 m (length-coded for system accuracy) |

| Construction | Shielded coaxial cable; non-armored jacket (chemically resistant) |

| Operating Temperature | Typically -51°C to +121°C for the cable (varies by jacket option) |

| Signal Type | Eddy-current proximity probe signal (dc-biased oscillator path) |

| Compatibility | 3300 XL 8 mm probes (e.g., 330103/330104) and 3300 XL 8 mm Proximitor sensors |

| Installation Method | Panel/cabinet or conduit routing; connects between probe and Proximitor sensor |

| Region Suffix | CN – commonly indicates China-market documentation/labeling |

Bently Nevada 330130-080-00-CN

Application Fields

This cable is typically specified for continuous vibration and axial position monitoring on rotating assets: steam and gas turbines, centrifugal compressors, critical pumps, gearboxes, and generators. I often see it used in refineries, petrochemical complexes, pipeline stations, steel and paper mills, and power plants where API 670 style monitoring is standard practice.

A maintenance lead at a combined-cycle plant told me they swapped in the 8 m variant during an outage to clean up lead dress and remove a splice; the proximity readings stabilized immediately after startup, which fits with how sensitive these systems are to exact cable length.

Advantages & Value

- Accuracy by design – Length-matched cable helps preserve the system’s factory calibration, reducing time spent on field tweaks.

- Reliability – Durable jacket and stable dielectric reduce drift and intermittent faults that can plague legacy cabling.

- Compatibility assurance – Works with standard 3300 XL 8 mm components many plants already stock, which typically simplifies spares management.

- Lifecycle cost – Fewer nuisance alarms and rework hours usually translate into lower maintenance cost across outages.

- Traceability – Genuine part numbering (including the CN suffix) supports clear documentation and QA audits.

Bently Nevada 330130-080-00-CN

Installation & Maintenance

- Routing – Run in metallic conduit or protected tray where feasible; avoid parallel runs beside VFD power cables to reduce noise pickup.

- Bend radius – You might notice performance issues with sharp bends; keep bends gentle and avoid crushing or kinking the coax.

- Connections – Seat connectors fully; finger-tighten per manufacturer practice. Do not splice the cable—use the correct length part.

- Environment – Maintain cabinet ventilation and keep the cable away from hot surfaces beyond its rating.

- Checks – During outages, inspect the jacket for nicks and verify continuity. If cable length changes, re-verify transducer system calibration.

- Cleaning – Wipe with lint-free cloth; avoid solvents that attack fluoropolymer jackets.

- Firmware/Monitoring – If you update the rack or monitor firmware, revalidate channel configuration for the installed cable length.

Quality & Certifications

- Certifications – CE and RoHS compliance are typical for this family; manufacturing under ISO 9001 quality systems.

- Standards alignment – When used with the 3300 XL 8 mm system, the setup is commonly aligned with API 670 monitoring practices.

- Warranty – Manufacturer’s standard limited warranty (commonly 1 year) on genuine parts.

If you’re standardizing lengths across a train, the 8.0 m option is a sensible middle ground—long enough for most compressors and smaller steam turbines, yet tidy in cabinets. From my experience, keeping all three components (probe, this cable, and the Proximitor) within the same 3300 XL 8 mm family avoids a lot of unnecessary troubleshooting.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: