Description

BENTLY 330100-90-01 3300 XL Proximity Probe System

Product Overview

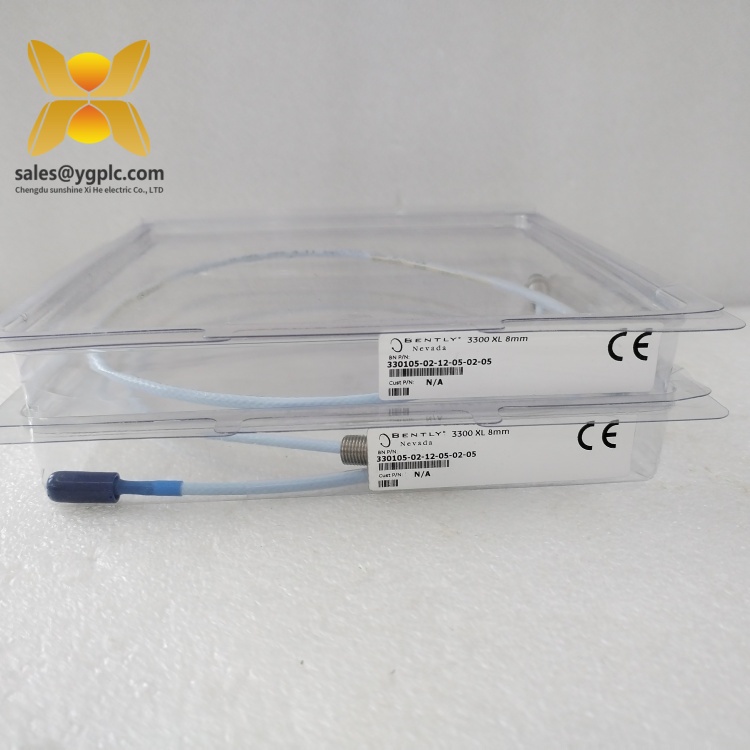

The BENTLY 330100-90-01 is a high-precision 3300 XL Proximity Probe System engineered for continuous monitoring of shaft displacement and vibration in critical rotating machinery. As a core component of Bently Nevada’s 3300 Series Machinery Protection System, this probe system converts mechanical movements into electrical signals, enabling real-time analysis of shaft position, vibration amplitude, and dynamic behavior in turbines, compressors, and generators. The 330100-90-01 integrates seamlessly with 3300 Series monitors (e.g., 3300/42M) and 3500 Series rack systems, delivering reliable measurements to support predictive maintenance and prevent catastrophic failures across industries such as oil & gas, power generation, and manufacturing.

Featuring a rugged stainless-steel construction, the BENTLY 330100-90-01 includes a proximity probe, extension cable, and position monitor designed for harsh industrial environments. The probe’s 8 mm diameter tip provides a measurement range of 0–250 mils (0–6.35 mm) with ±0.5% linearity, ensuring precise detection of shaft movements. Its hermetically sealed enclosure (IP65-rated) and corrosion-resistant materials protect against dust, moisture, and chemical exposure, while the system’s wide temperature range (-40°C to +177°C) makes it suitable for high-temperature applications like turbine casings. The 330100-90-01 supports standard 2-wire installations, simplifying integration with existing monitoring networks and reducing installation complexity.

In automation ecosystems, the 330100-90-01 serves as the front-end sensor for machinery protection systems, feeding real-time displacement data to monitoring modules for trend analysis, alarm activation, and shutdown triggering. Its compatibility with industry standards (e.g., API 670) ensures compliance with safety regulations, while the low-output impedance and built-in signal conditioning minimize electromagnetic interference. By providing actionable insights into shaft health, this probe system helps reduce unplanned downtime, optimize maintenance schedules, and extend equipment lifespan in mission-critical operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 330100-90-01 |

| Manufacturer | Bently Nevada |

| Product Type | Proximity Probe System |

| Series | 3300 XL |

| Probe Tip Diameter | 8 mm |

| Measurement Range | 0–250 mils (0–6.35 mm) |

| Linearity | ±0.5% of full scale |

| Output Signal | 4–20 mA (proportional to displacement) |

| Excitation Voltage | 24 V DC (supplied by monitor) |

| Physical Dimensions | Probe: 8 mm (diameter) × 50 mm (length); Extension Cable: 9 m; Position Monitor: 76 mm × 51 mm × 25 mm |

| Weight | 0.4 kg (probe and cable) |

| Operating Temperature | Probe: -40°C to +177°C; Position Monitor: -40°C to +85°C |

| Mounting | Threaded (1/2-20 UNF or M14×1.5) |

| Environmental Rating | IP65, NEMA 4X |

Key Features and Advantages

High-Accuracy Displacement Measurement: The 330100-90-01 provides precise shaft displacement readings with ±0.5% linearity, enabling early detection of misalignment, bearing wear, or shaft rubs. Its wide measurement range (0–250 mils) accommodates both small and large machinery movements, supporting comprehensive health analysis for rotating equipment.

Rugged Industrial Design: The probe’s stainless-steel housing and IP65 rating protect against harsh environmental factors, including water jets, dust, and corrosive gases. The system’s high-temperature tolerance (probe up to +177°C) allows direct mounting on hot surfaces like turbine casings without additional cooling, ensuring reliability in extreme operating conditions.

Seamless System Integration: Compatible with BENTLY’s 3300 and 3500 Series monitoring systems, the 330100-90-01 simplifies integration with existing infrastructure. The standard 2-wire configuration and industry-standard 4–20 mA output enable easy connectivity to PLCs, DCS, and SCADA systems, reducing integration costs and engineering time.

Low Noise and High Reliability: The built-in signal conditioning and shielded cable minimize electromagnetic interference, ensuring clean displacement signals even in high-noise environments. The probe’s non-contact sensing principle eliminates wear and tear, enhancing long-term reliability and reducing maintenance requirements for critical machinery.

Flexible Application Scope: Suitable for both radial vibration and axial displacement monitoring, the 330100-90-01 supports diverse machinery types, from small motors to large turbines. Its modular design (probe, cable, monitor) allows flexible installation in tight spaces or remote locations, adapting to complex industrial setups.

Application Areas

The BENTLY 330100-90-01 is essential for machinery health monitoring in industries where equipment reliability is critical:

- Oil & Gas: Monitors shaft displacement in compressors, pumps, and turbines at refineries, pipelines, and offshore platforms to detect misalignment or bearing degradation, preventing costly unplanned shutdowns and ensuring operational continuity.

- Power Generation: Installed on steam turbines, generators, and auxiliary equipment in thermal, hydro, and nuclear plants to ensure safe operation, optimize energy production, and maintain grid stability through real-time shaft position analysis.

- Manufacturing: Used in high-speed rotating machinery (e.g., motors, fans, conveyors) in automotive, chemical, and food processing facilities to maintain production quality, reduce mechanical stress, and prevent equipment failures that could disrupt workflows.

- Aerospace & Defense: Deployed on test stands and propulsion systems to analyze shaft dynamics, ensuring compliance with rigorous performance standards and safety regulations for critical aerospace components.

Specific applications include:

- Radial Vibration Analysis: Measures shaft vibration amplitude to identify imbalance or misalignment issues before they escalate, enabling proactive maintenance and reducing repair costs.

- Axial Displacement Monitoring: Tracks thrust bearing wear in turbines and compressors, triggering alarms when clearances exceed safe limits to prevent metal-to-metal contact and catastrophic failure.

- Shaft Position Sensing: Monitors rotor position in steam turbine lube oil systems or high-speed rotating machinery to ensure proper alignment and prevent operational anomalies.

Related Products

- BENTLY 330700 Proximity Probe System: A 5 mm tip variant for smaller machinery, offering similar functionality with a reduced measurement range, ideal for compact equipment or tight installation spaces.

- BENTLY 330500 Proximity Probe System: A 11 mm tip model designed for large shafts, compatible with the 330100-90-01 in multi-probe monitoring setups for comprehensive machinery health analysis.

- BENTLY 3300/42M Vibration Monitor: Processes signals from the 330100-90-01 to provide real-time vibration analysis, alarm outputs, and data trending for predictive maintenance.

- BENTLY 3500/42M Proximitor Monitor: Integrates with the 330100-90-01 in 3500 Series racks, offering advanced machinery protection features and compatibility with higher-level control systems.

- BENTLY 330903 Extension Cable: Extends the 330100-90-01 system for remote mounting, available in various lengths (e.g., 15 m, 30 m) to accommodate diverse installation requirements.

- BENTLY 330103 Probe Housing: A mounting accessory for the 330100-90-01 probe, ensuring secure installation on machinery casings and protecting against environmental factors.

Installation and Maintenance

Pre-installation Preparations:

Before installing the BENTLY 330100-90-01, verify the mounting surface is flat and free of debris. Use a torque wrench to secure the probe housing (recommended torque: 11–14 N·m) and route the 9 m extension cable away from high-voltage lines to minimize electromagnetic interference. Connect the position monitor to the 3300 Series rack or standalone monitor, ensuring proper grounding to reduce noise. Calibrate the system with a known displacement source (e.g., calibration fixture) to validate measurement accuracy before commissioning, ensuring the 330100-90-01 functions within specified tolerances.

Before installing the BENTLY 330100-90-01, verify the mounting surface is flat and free of debris. Use a torque wrench to secure the probe housing (recommended torque: 11–14 N·m) and route the 9 m extension cable away from high-voltage lines to minimize electromagnetic interference. Connect the position monitor to the 3300 Series rack or standalone monitor, ensuring proper grounding to reduce noise. Calibrate the system with a known displacement source (e.g., calibration fixture) to validate measurement accuracy before commissioning, ensuring the 330100-90-01 functions within specified tolerances.

Maintenance Suggestions:

- Routine Inspections: Conduct quarterly visual checks for loose connections, cable wear, or corrosion on the probe and monitor. Use a handheld vibrometer to compare 330100-90-01 readings with reference sensors, documenting any deviations for timely calibration adjustments.

- Cleaning and Protection: Remove dust and debris from the probe tip and housing using a dry cloth or compressed air, particularly in dusty environments. Avoid using solvents that may damage the probe’s protective coating, ensuring long-term measurement reliability.

- Periodic Calibration: Annually calibrate the 330100-90-01 using a precision displacement shaker to maintain measurement accuracy. Document calibration results for compliance with industry standards and to track performance trends over time.

- Spare Parts Management: Store spare 330100-90-01 probes and monitors in a temperature-controlled environment (10–30°C) with low humidity to preserve functionality. Test spares periodically to ensure they are ready for immediate deployment during unexpected failures.

Product Guarantee

Our company provides a 12-month quality warranty for the BENTLY 330100-90-01, covering hardware defects under normal use. In the event of abnormal performance—such as signal instability or measurement drift—we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the 330100-90-01 and related spares. Our technical support team assists with installation, calibration, and troubleshooting, delivering reliable solutions to maintain the integrity of your industrial monitoring systems.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

BENTLY 350022 288055-01 DCS

BENTLY 135489-02 rack

BENTLY 135031-01 Main processor

BENTLY 3500/44M 140734-03 Pulse input

BENTLY 3500/94 147663-01 Switch quantity input card

BENTLY 350022 288055-01 programmable

BENTLY 135489-02 Logic controller

BENTLY 135031-01 Double output

BENTLY 3500/44M 140734-03 Expansion module

BENTLY 3500/54 133396-01 RXM rack

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: