Description

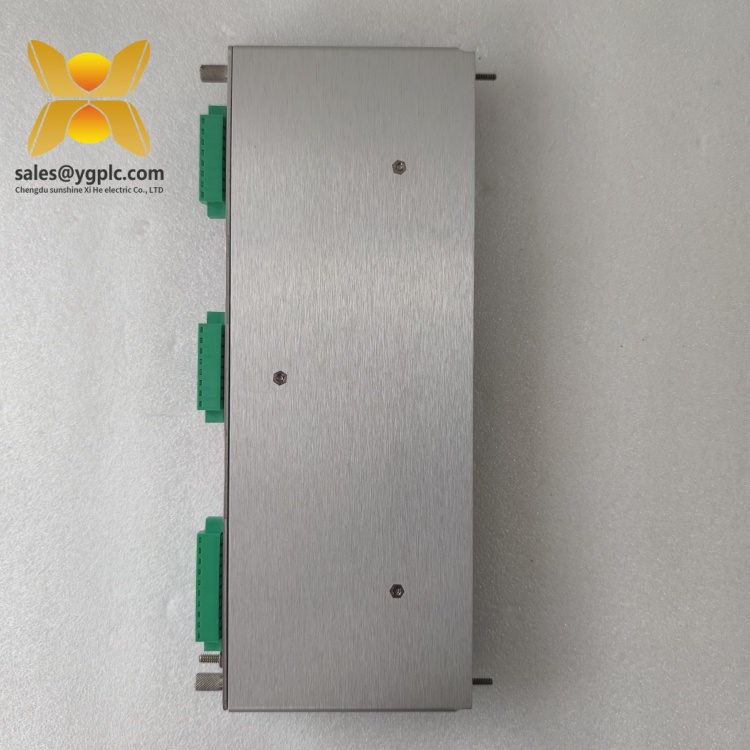

BENTLY 2300/25-00 Vibration Monitoring System

Product Overview

The BENTLY 2300/25-00 is a high-performance vibration monitoring system designed for critical machinery health assessment in industrial automation environments. As part of Bently Nevada’s 2300 Series, this system serves as a portable yet robust solution for measuring vibration velocity and displacement in rotating equipment such as turbines, compressors, and generators. Engineered to deliver real-time vibration analysis, the 2300/25-00 enables predictive maintenance by converting mechanical vibrations into actionable data, helping industries like oil & gas, power generation, and manufacturing prevent unplanned downtime and extend equipment lifespan.

Featuring a rugged handheld design, the BENTLY 2300/25-00 integrates a high-sensitivity piezoelectric sensor with advanced signal conditioning, capturing vibration velocities from 0.1 to 100 in/sec (2.54 to 2540 mm/sec) with ±1% accuracy. Its intuitive LCD display and menu-driven interface allow operators to quickly access trend data, 频谱分析 (spectrum analysis), and alarm settings, while the built-in data logging function stores up to 1000 measurement profiles for later analysis. The system’s compatibility with BENTLY’s 3500 Series rack-mounted monitors ensures seamless integration into existing machinery protection systems, providing both portable diagnostics and permanent monitoring capabilities.

In automation ecosystems, the 2300/25-00 bridges the gap between periodic maintenance and continuous monitoring, offering flexibility for on-site inspections or temporary system upgrades. Its wide operating temperature range (-40°C to +50°C) and IP65-rated enclosure make it suitable for harsh environments, while the rechargeable battery supports up to 8 hours of continuous use. By combining precision measurement with field-ready durability, this system empowers maintenance teams to detect early signs of equipment degradation, optimize repair schedules, and enhance overall operational efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 2300/25-00 |

| Manufacturer | Bently Nevada |

| Product Type | Vibration Monitoring System |

| Sensing Element | Piezoelectric ceramic |

| Measurement Range | Velocity: 0.1–100 in/sec (2.54–2540 mm/sec); Displacement: 0–250 mils (0–6.35 mm) |

| Frequency Response | 10–10,000 Hz |

| Output Signal | 4–20 mA (via optional interface), USB data export |

| Display | 3.5-inch color LCD (320×240 pixels) |

| Battery Life | Up to 8 hours (rechargeable Li-ion) |

| Physical Dimensions | 220 mm (H) × 100 mm (W) × 50 mm (D) |

| Weight | 0.9 kg |

| Operating Temperature | -40°C to +50°C |

| Environmental Rating | IP65, NEMA 4X |

| Data Storage | 1000+ measurement profiles |

Key Features and Advantages

High-Precision Vibration Analysis: The 2300/25-00 delivers ±1% accurate vibration measurements, enabling early detection of subtle mechanical issues like bearing wear or shaft imbalance. Its wide frequency response captures both low-frequency structural vibrations and high-frequency bearing defects, providing comprehensive machinery health insights.

Portable and Rugged Design: The handheld form factor and IP65-rated enclosure make the system suitable for field use in harsh environments, while the rechargeable battery supports extended on-site inspections. The rugged housing withstands drops and vibrations, ensuring reliability in industrial settings.

Intuitive User Interface: The color LCD and menu-driven controls allow operators to quickly access key metrics, set alarm thresholds, and export data via USB. The system’s built-in trend analysis tools help identify developing issues without requiring external software.

Seamless System Integration: Compatible with BENTLY’s 3500 Series monitoring systems, the 2300/25-00 enables data synchronization with permanent rack-mounted solutions, supporting both portable diagnostics and long-term trend analysis. This flexibility reduces the need for multiple monitoring platforms.

Comprehensive Data Logging: The system stores detailed measurement profiles, including time-stamped vibration data and 频谱 (spectra), enabling historical trend analysis and compliance reporting. Data can be exported to PCs for further analysis using BENTLY’s proprietary software.

Application Areas

The BENTLY 2300/25-00 is ideal for industries requiring portable yet precise vibration monitoring:

- Oil & Gas: Conducts routine vibration surveys on offshore compressors, pipeline pumps, and refinery turbines to detect early signs of mechanical degradation, preventing costly shutdowns.

- Power Generation: Monitors steam turbines, generators, and auxiliary equipment in thermal and renewable energy plants, ensuring optimal performance and grid stability.

- Manufacturing: Inspects high-speed motors, fans, and conveyor systems in automotive, chemical, and food processing facilities to maintain production continuity and product quality.

- Mining and Metals: Evaluates vibrations in crushers, mills, and ventilation systems to minimize downtime and extend equipment life in harsh mining environments.

Specific applications include:

- Route-Based Maintenance: Performs periodic vibration checks on critical assets, replacing manual data collection with automated, repeatable measurements.

- Troubleshooting: Diagnoses vibration-related issues on-site, such as identifying the root cause of excessive vibrations in rotating machinery.

- Commissioning and Acceptance Testing: Verifies equipment health during installation or after repairs, ensuring compliance with operational standards.

Related Products

- BENTLY 2300/10-00 Vibration Meter: A basic variant with limited features, suitable for entry-level vibration monitoring.

- BENTLY 3500/42M Vibration Monitor: A rack-mounted solution for continuous monitoring, often used alongside the 2300/25-00 for permanent installations.

- BENTLY 2300/90-00 Data Analysis Software: Enhances the 2300/25-00 with advanced analytics, enabling trend visualization and predictive maintenance modeling.

- BENTLY 3300 XL Proximity Probe System: A complementary displacement sensor for shaft position monitoring, used in conjunction with the 2300/25-00 for comprehensive machinery analysis.

- BENTLY 2300/30-00 Acceleration Sensor: An optional high-frequency sensor for the 2300/25-00, improving detection of bearing defects.

- BENTLY 2300/80-00 Charging Station: Multi-unit charging solution for fleet management of 2300/25-00 systems in large facilities.

Installation and Maintenance

Pre-installation Preparations:

Before using the BENTLY 2300/25-00, ensure the sensor tip is clean and free of debris. Calibrate the system using BENTLY’s official calibration fixture to validate measurement accuracy. Familiarize yourself with the menu interface via the user manual, and ensure the battery is fully charged for extended use. For portable use, attach the sensor to the machinery using a magnetic base or threaded mount, ensuring optimal vibration transfer.

Before using the BENTLY 2300/25-00, ensure the sensor tip is clean and free of debris. Calibrate the system using BENTLY’s official calibration fixture to validate measurement accuracy. Familiarize yourself with the menu interface via the user manual, and ensure the battery is fully charged for extended use. For portable use, attach the sensor to the machinery using a magnetic base or threaded mount, ensuring optimal vibration transfer.

Maintenance Suggestions:

- Routine Checks: After each use, inspect the sensor and cable for physical damage. Clean the sensor tip with a dry cloth to remove dust or debris that could affect readings.

- Battery Management: Charge the battery regularly to maintain capacity, avoiding deep discharges. Store spare batteries in a cool, dry place for field replacements.

- Calibration Schedule: Perform annual calibration using BENTLY’s vibration shaker table to maintain measurement accuracy. Document calibration results for compliance.

- Software Updates: Periodically check for firmware updates on BENTLY’s website, applying them via USB to access new features and bug fixes.

Product Guarantee

Our company provides a 12-month quality warranty for the BENTLY 2300/25-00, covering hardware defects under normal use. In the event of performance issues—such as inaccurate readings or display malfunctions—we offer prompt replacement services to minimize downtime. For urgent or legacy requirements, our global supply chain ensures rapid delivery of the 2300/25-00 and related accessories. Our technical support team is available 24/7 to assist with calibration, software setup, and troubleshooting, ensuring reliable operation to support your maintenance strategies.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

BENTLY 3500/32 125720-01 Power source

BENTLY 3500/45 176449-04 base

BENTLY 3500/65 145988-02 exchange

BENTLY 3500/22M 138607-01 Expansion rack

BENTLY 3500/94 147663-01 Switch quantity input card

BENTLY 3701/55 Enhanced intelligent communication module

BENTLY 3500/45 176449-04 base

BENTLY 3500/65 145988-02 exchange

BENTLY 3500/45 176449-04 base

BENTLY 3500/65 145988-02 exchange

BENTLY 3500/22M 138607-01 Expansion rack

BENTLY 3500/94 147663-01 Switch quantity input card

BENTLY 3701/55 Enhanced intelligent communication module

BENTLY 3500/45 176449-04 base

BENTLY 3500/65 145988-02 exchange

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: