Description

BENTLY 1900/65A-00-01-01-01-01 Product Specification

Product Overview :BENTLY 1900/65A-00-01-01-01-01

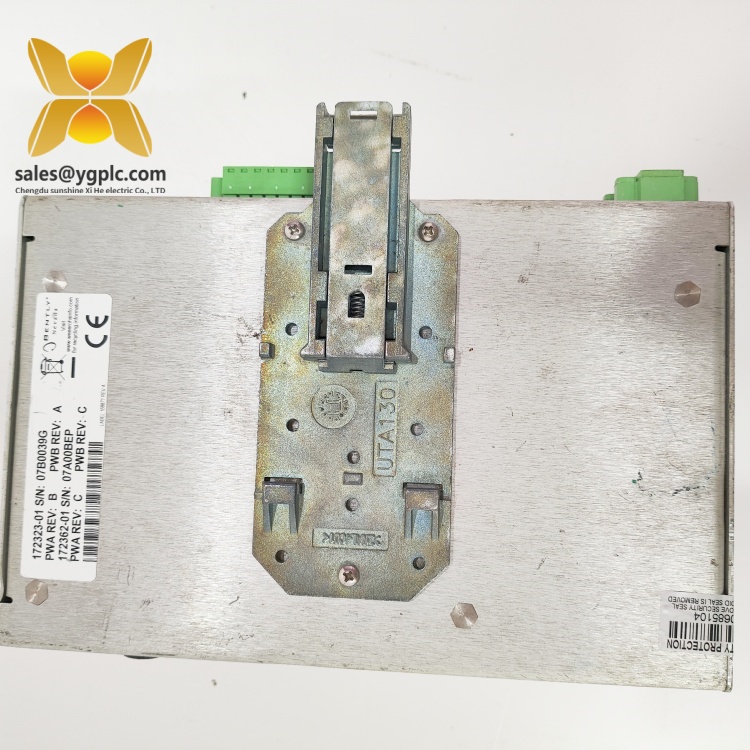

The BENTLY 1900/65A-00-01-01-01-01 is a high-performance general-purpose equipment monitor designed for continuous vibration and temperature monitoring in rotating machinery. Engineered by Bently Nevada, a global leader in machinery health solutions, this module is part of the 1900 series, renowned for its reliability and flexibility in industrial applications. The BENTLY 1900/65A-00-01-01-01-01 serves as a critical component in predictive maintenance systems, enabling real-time analysis of equipment health to prevent unplanned downtime in industries such as power generation, oil and gas, and manufacturing.

Featuring four configurable transducer inputs and four temperature channels, the BENTLY 1900/65A-00-01-01-01-01 supports a wide range of sensors, including accelerometers, velocity probes, and proximity sensors, as well as thermocouples and RTDs for temperature measurement 12. This versatility allows it to monitor key parameters such as vibration amplitude, bearing temperature, and shaft displacement, providing actionable insights for proactive maintenance. The module’s built-in Modbus communication interface (Ethernet and RS232/485) enables seamless integration with distributed control systems (DCS) and SCADA platforms, facilitating remote configuration and data logging.

In automation systems, the BENTLY 1900/65A-00-01-01-01-01 acts as a frontline diagnostic tool, converting raw sensor data into meaningful metrics for equipment performance evaluation. Its dual-channel relay outputs (six in total) and 4–20 mA analog outputs enable precise alarm triggering and data transmission to higher-level systems 1. With a compact DIN rail-mountable design and rugged construction, the module withstands harsh industrial environments, including extreme temperatures (-40°C to +70°C) and high vibration, ensuring reliable operation in demanding settings.

Technical Specifications :BENTLY 1900/65A-00-01-01-01-01

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 1900/65A-00-01-01-01-01 |

| Manufacturer | Bently Nevada |

| Product Type | Machinery Vibration and Temperature Monitor |

| Input Channels | 4 transducer inputs (configurable for accelerometers, velocity sensors, etc.) |

| Temperature Inputs | 4 channels (supporting Type E, J, K, T thermocouples and 2/3-wire RTDs) |

| Outputs | 6 relay outputs, 4 × 4–20 mA analog outputs, buffered signal outputs |

| Communication | Modbus RTU/ASCII (RS232/485) and Modbus TCP/IP (Ethernet) |

| Power Supply | 120/240 VAC ±10%, 50/60 Hz |

| Physical Dimensions | 178 mm (W) × 102 mm (H) × 254 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -40°C to +70°C |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Certifications | CE, UL, CSA |

BENTLY 1900 65A-00-00-01-00-01

Main Features and Advantages :BENTLY 1900/65A-00-01-01-01-01

Multi-Parameter Monitoring: The BENTLY 1900/65A-00-01-01-01-01 combines vibration analysis with temperature monitoring, offering a comprehensive view of machinery health. Its configurable transducer inputs adapt to various sensor types, eliminating the need for specialized modules and reducing system complexity 1.

Real-Time Diagnostics: Built-in signal conditioning and analysis algorithms enable real-time detection of anomalies such as misalignment, bearing wear, or unbalance. The module’s front-panel LED indicators and Modbus-compatible interface provide instant status updates, while its buffered outputs allow for post-fault signal analysis 2.

Flexible Configuration: Using Bently Nevada’s 1900 Configuration Software, users can customize alarm thresholds, sensor scaling, and relay logic to match specific application requirements. The module stores configurations in non-volatile memory, ensuring data integrity during power cycles 1.

Rugged Industrial Design: Constructed with a reinforced metal casing and conformal-coated PCBs, the BENTLY 1900/65A-00-01-01-01-01 resists dust, moisture, and electromagnetic interference (EMI), making it suitable for harsh environments like offshore platforms or power plant control rooms 2.

Cost-Effective Solution: By integrating multiple monitoring functions into a single unit, the BENTLY 1900/65A-00-01-01-01-01 reduces hardware costs and simplifies installation compared to legacy systems. Its compatibility with industry-standard protocols (e.g., Modbus) ensures seamless integration with existing infrastructure

BENTLY 1900 65A-00-00-01-00-01

Application Areas :BENTLY 1900/65A-00-01-01-01-01

The BENTLY 1900/65A-00-01-01-01-01 is widely deployed in industries where rotating machinery reliability is critical:

-

Power Generation:

- Monitors steam and gas turbines, generators, and pumps to optimize performance and prevent catastrophic failures.

- Supports predictive maintenance programs by analyzing vibration trends and temperature fluctuations.

-

Oil and Gas:

- Integrates with compressors, centrifuges, and pumps in refineries and offshore platforms to ensure safe and efficient operations.

- Detects early signs of equipment degradation, reducing maintenance costs and downtime.

-

Manufacturing:

- Enhances productivity in automotive and pharmaceutical plants by monitoring conveyor systems, motors, and gearboxes.

- Enables condition-based maintenance to minimize production interruptions.

-

Water and Wastewater:

- Manages pump stations and treatment equipment, ensuring compliance with environmental standards.

- Provides remote access for diagnostic and configuration tasks, reducing on-site visits.

BENTLY 1900 65A-00-00-01-00-01

Related Products :BENTLY 1900/65A-00-01-01-01-01

- BENTLY 1900/27: A high-accuracy vibration monitoring system with advanced signal processing capabilities, ideal for critical rotating machinery 5.

- BENTLY 3300/32: A proximity probe monitor for shaft displacement and velocity measurements, often used alongside the 1900/65A in turbomachinery applications.

- BENTLY 3500/42M: A machinery protection system module that complements the 1900/65A by providing additional redundancy and safety features.

- BENTLY 3500/22M: A rack-mounted controller for integrating multiple 1900 series modules into a centralized monitoring network.

- BENTLY 4200/01: A high-speed data acquisition system for detailed vibration analysis, supporting advanced diagnostic workflows.

Installation and Maintenance :BENTLY 1900/65A-00-01-01-01-01

Pre-installation Preparation:

Before installing the BENTLY 1900/65A-00-01-01-01-01, ensure the following:

Before installing the BENTLY 1900/65A-00-01-01-01-01, ensure the following:

- Verify the power supply matches the module’s requirements (120/240 VAC) and that the control rack is properly grounded.

- Use Bently Nevada’s configuration software to define sensor types, alarm thresholds, and communication parameters.

- Mount the module on a DIN rail with adequate clearance for heat dissipation.

Maintenance Recommendations:

- Routine Inspections: Check front-panel LEDs monthly to confirm normal operation. Replace faulty modules immediately to avoid cascading system failures.

- Calibration: Perform annual calibration of sensor inputs using certified test equipment to maintain accuracy.

- Firmware Updates: Periodically update the module’s firmware via the configuration software to access new features and security patches.

- Environmental Checks: Clean dust from vents quarterly and monitor ambient conditions to ensure they remain within specified ranges.

BENTLY 1900 65A-00-00-01-00-01

Product Warranty :BENTLY 1900/65A-00-01-01-01-01

Our company provides a one-year quality warranty for the BENTLY 1900/65A-00-01-01-01-01, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models or urgent needs, our global supply chain network ensures rapid response to scarce spare parts requests, supporting the continuous and stable operation of industrial systems.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This product description is based on publicly available technical data and industry applications. For detailed specifications, consult the official Bently Nevada datasheet or contact our technical support team.

BENTLY 3500/92 136180-01 Fault tolerant control system

BENTLY 3500/15 114M5330-01 Digital input module

BENTLY 3500/77M 176449-07 Safety system module

BENTLY 3500/54 133396-01 Network communication card

BENTLY 3500/32 125720-01 Digital oscilloscope

BENTLY 3500/45 176449-04 DI connection base plate

BENTLY 3500/65 145988-02 DO connection base plate

BENTLY 330876-03-50-00-00 Card module

BENTLY 3500/22M 138607-01 DCS card

BENTLY 3500/93 135785-02C DI card

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: