Description

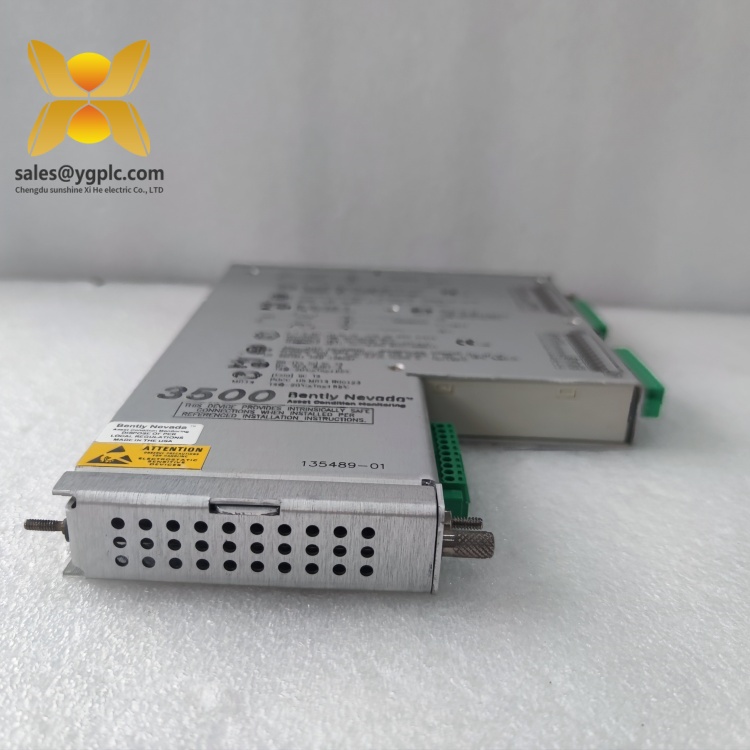

BENTLY 135489-03 Extension Cable

Product Overview: BENTLY 135489-03

The BENTLY 135489-03 extension cable is a high-reliability industrial connectivity solution designed for extending the reach of vibration monitoring systems in harsh industrial environments. As a critical component of Bently Nevada’s 3300 Series Machinery Health Monitoring System, this cable bridges the gap between proximity probes and monitoring modules, enabling precise measurement of shaft vibration and displacement in rotating machinery. Engineered for durability and signal integrity, the 135489-03 ensures seamless data transmission in mission-critical applications where equipment health monitoring is essential.

Featuring a 3-meter length and rugged stainless-steel braiding, the 135489-03 withstands mechanical stress, corrosion, and electromagnetic interference (EMI), making it suitable for use in power plants, refineries, and manufacturing facilities. The cable’s 18-pin Bently Nevada connector ensures a secure, corrosion-resistant connection to both probes (e.g., 106M1081-01) and Proximitor modules (e.g., 3300/40M 173343-01), minimizing signal loss and noise interference. Its -50°C to +177°C operating temperature range and IP65 protection rating further enhance reliability in extreme environmental conditions, from high-temperature turbine compartments to offshore platforms.

In automation systems, the 135489-03 plays a pivotal role in expanding the physical reach of vibration monitoring setups, allowing probes to be positioned in hard-to-reach areas while maintaining measurement accuracy. Its compatibility with Bently Nevada’s comprehensive suite of monitoring components ensures seamless integration into distributed control systems (DCS) and supervisory control networks, supporting predictive maintenance strategies that reduce unplanned downtime.

Technical Specifications: BENTLY 135489-03

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 135489-03 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Extension Cable |

| Cable Length | 3 meters |

| Connector Type | 18-pin Bently Nevada compatible |

| Shielding | Stainless steel braid |

| Operating Temperature | -50°C to +177°C |

| Storage Temperature | -50°C to +200°C |

| Protection Rating | IP65 |

| Cable Material | Polyvinyl chloride (PVC) jacket |

| Weight | 0.5 kg |

| Country of Origin | United States |

Main Features and Advantages: BENTLY 135489-03

Rugged Industrial Design: The 135489-03 features a stainless-steel braided shield that resists abrasion, corrosion, and EMI, ensuring signal integrity in high-vibration and electrically noisy environments. This durability reduces the risk of cable failure, minimizing maintenance costs and downtime.

Precision Signal Transmission: Engineered for minimal signal loss, the cable maintains the high sensitivity (7.87 V/mm) of Bently Nevada proximity probes, enabling accurate vibration measurements even over extended distances. Its low capacitance and impedance characteristics preserve measurement fidelity critical for early fault detection.

Wide Environmental Tolerance: With an operating range of -50°C to +177°C, the 135489-03 withstands extreme temperatures encountered in industrial settings, from arctic oil fields to high-temperature furnace applications. The IP65 rating protects against dust and water jets, enhancing reliability in harsh conditions.

Seamless System Integration: Designed specifically for Bently Nevada’s 3300 Series, the cable ensures plug-and-play compatibility with Proximitor modules, probes, and rack systems. This standardization simplifies installation and reduces the risk of compatibility issues in complex monitoring setups.

Easy Installation and Maintenance: The cable’s flexible design and lightweight construction facilitate routing through tight spaces, while its corrosion-resistant connectors require minimal maintenance. Regular visual inspections (e.g., for abrasion or connector degradation) ensure long-term performance.

Application Areas: BENTLY 135489-03

The BENTLY 135489-03 extension cable is essential for industries requiring robust vibration monitoring over extended distances:

- Power Generation: Connects vibration probes to monitoring systems in steam turbines, generators, and auxiliary equipment, enabling real-time health assessment in power plants. The cable’s high-temperature tolerance suits direct installation near hot turbine casings.

- Oil and Gas: Deployed in offshore platforms and refineries to extend probe reach in compressors, pumps, and motors. Its corrosion resistance makes it suitable for saltwater environments and chemically active processing areas.

- Manufacturing: Used in CNC machines, presses, and robotic arms to monitor vibrations that could affect product quality. The cable’s EMI shielding ensures measurement accuracy in electrically noisy production floors.

- Water Treatment: Links vibration sensors to control systems in pump stations and wastewater treatment plants, supporting continuous operation and regulatory compliance.

- Aerospace and Defense: Integrates with ground support equipment and military machinery, where reliable vibration data is critical for mission readiness and safety.

Related Products: BENTLY 135489-03

- BENTLY 106M1081-01 Vibration Proximity Probe: A 配套使用 probe that connects to the 135489-03, providing precise shaft vibration measurements.

- BENTLY 3300/40M Proximitor Module (173343-01): Processes signals from the probe via the 135489-03, converting mechanical movements into electrical outputs.

- BENTLY 3300/32 Keyphasor Module (125712-01): Works with the 135489-03 to provide phase reference signals for vibration analysis.

- BENTLY 3300/05 Rack Chassis: Houses Proximitor modules connected via the 135489-03, forming a comprehensive monitoring system.

- BENTLY 135490-05 Extension Cable (5-meter): A longer variant of the 135489-03 for applications requiring greater reach.

- BENTLY 133488-02 Connector Kit: Replacement connectors for the 135489-03, ensuring secure terminations during installation or repair.

Installation and Maintenance: BENTLY 135489-03

Pre-installation Preparations:

Before installing the 135489-03, inspect the cable for physical damage and ensure the connector pins are clean and corrosion-free. Verify the installation route to avoid sharp bends or exposure to extreme temperatures. Use cable ties or conduits to secure the cable, maintaining a minimum bending radius of 50 mm to prevent internal wire damage. Connect one end to the proximity probe (e.g., 106M1081-01) and the other to the Proximitor module (e.g., 3300/40M 173343-01), ensuring the connector latches are fully engaged.

Before installing the 135489-03, inspect the cable for physical damage and ensure the connector pins are clean and corrosion-free. Verify the installation route to avoid sharp bends or exposure to extreme temperatures. Use cable ties or conduits to secure the cable, maintaining a minimum bending radius of 50 mm to prevent internal wire damage. Connect one end to the proximity probe (e.g., 106M1081-01) and the other to the Proximitor module (e.g., 3300/40M 173343-01), ensuring the connector latches are fully engaged.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks for abrasion, fraying, or connector degradation. Use a thermal imager to detect unusual temperature spots that may indicate internal wire issues.

- Environmental Monitoring: Regularly assess the cable’s operating environment for changes in temperature, humidity, or mechanical stress. Add additional shielding or reroute the cable if conditions exceed specified limits.

- Connector Care: Annually clean connector contacts with isopropyl alcohol to remove oxidation, ensuring optimal signal transmission. Tighten any loose connections to prevent intermittent failures.

- Spare Parts Management: Keep a spare 135489-03 on hand, along with connector kits, to facilitate rapid replacement in case of failure. Leverage our global supply chain for quick delivery of discontinued components.

Product Guarantee: BENTLY 135489-03

Our company provides a 12-month quality warranty for the BENTLY 135489-03 extension cable, covering hardware defects from non-human causes. During the warranty period, we will replace any cable with shielding damage, connector failures, or signal degradation at no cost. For urgent needs or discontinued models, our extensive inventory and global logistics network ensure prompt fulfillment, minimizing downtime and supporting continuous industrial operation.

With 17 years of expertise in industrial control distribution, we prioritize reliable products and exceptional service. The 135489-03 exemplifies our commitment to quality, offering the durability and signal integrity required for critical machinery monitoring. Contact us today to enhance your vibration monitoring setup with this robust extension cable.

Note: All product names, logos, and brands are property of their owners. This document is informational and does not substitute for Bently Nevada’s official technical manuals.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

BENTLY 330876-03-50-00-00 DI module

BENTLY 3500/54 133396-01 Thermoelectric couple

BENTLY 3500/45 176449-04 S100

BENTLY 3500/65 145988-02 I/O

BENTLY 330876-03-50-00-00 S200

BENTLY 3500/22M 138607-01 S400

BENTLY 135489-02 Main processor

BENTLY 3500-20 Pulse input

BENTLY 135031-01 Analog quantity

BENTLY 3500/44M 140734-03 Digital quantity

BENTLY 3500/54 133396-01 Connection base plate

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: