Description

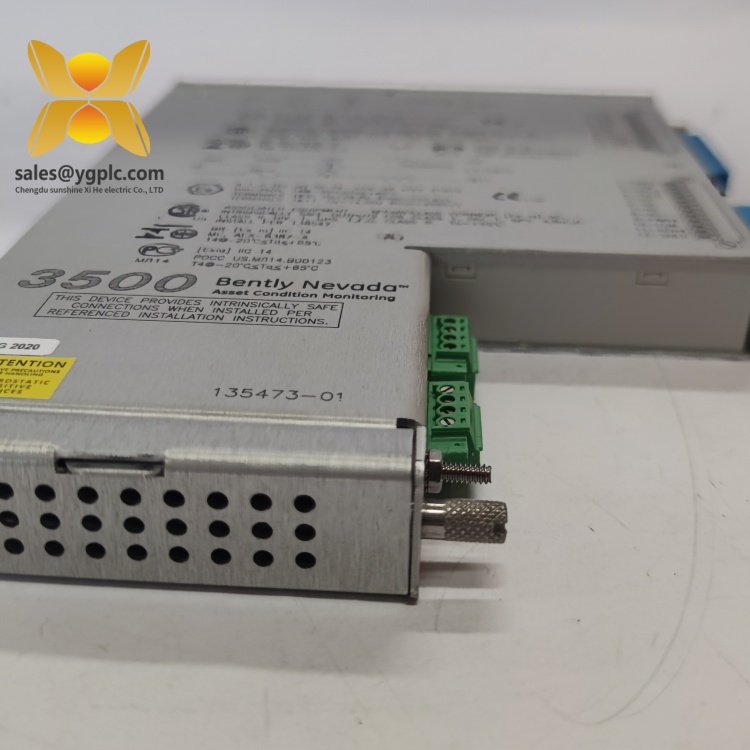

BENTLY 135473-01 Accelerometer Sensor

Product Overview

The BENTLY 135473-01 is a high-precision accelerometer sensor engineered for continuous vibration monitoring in critical industrial machinery. As a key component of Bently Nevada’s 3500 Series Machinery Protection System, this sensor converts mechanical vibrations into electrical signals for real-time analysis, enabling predictive maintenance and early fault detection in turbines, compressors, and generators. The 135473-01 integrates seamlessly with BENTLY’s monitoring platforms, delivering reliable acceleration data to support operational safety and efficiency across oil & gas, power generation, and manufacturing sectors.

Designed with a rugged piezoelectric element, the BENTLY 135473-01 measures vibration acceleration ranging from 0 to 50 g with ±1% accuracy, ensuring precise data acquisition in high-vibration environments. Its hermetically sealed stainless-steel enclosure (IP67-rated) and shock resistance (1000 g) protect against dust, moisture, and mechanical stress, making it suitable for harsh industrial settings. The sensor’s 4–20 mA output signal and built-in signal conditioning minimize noise interference, while its compatibility with standard 2-wire installations simplifies integration into existing monitoring networks.

In automation ecosystems, the 135473-01 serves as the front-end sensing device for vibration analysis, feeding real-time acceleration data to 3500 Series monitors for trend analysis and alarm activation. Its wide frequency response (10 to 10,000 Hz) enables detection of various fault signatures, from bearing wear to structural resonance. By providing actionable insights into equipment health, this sensor helps reduce unplanned downtime, extend component lifespan, and optimize maintenance schedules in mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 135473-01 |

| Manufacturer | Bently Nevada |

| Product Type | Accelerometer Sensor |

| Sensing Element | Piezoelectric ceramic |

| Measurement Range | 0–50 g (0–490.3 m/s²) |

| Frequency Response | 10–10,000 Hz |

| Output Signal | 4–20 mA (loop-powered) |

| Sensitivity | 100 mV/g (10.2 mV/(m/s²)) |

| Physical Dimensions | 38 mm (diameter) × 76 mm (length) |

| Weight | 0.45 kg |

| Operating Temperature | -40°C to +121°C |

| Mounting | Threaded mounting (1/2-20 UNF or M14×1.5) |

| Environmental Rating | IP67, NEMA 4X |

| Shock Resistance | 1000 g (11 ms) |

Key Features and Advantages

High-Accuracy Vibration Measurement: The 135473-01 provides precise acceleration readings with ±1% accuracy, enabling early detection of subtle mechanical issues. Its wide frequency response captures both low-frequency imbalance and high-frequency bearing defects, supporting comprehensive machinery health analysis.

Rugged Industrial Design: The sensor’s hermetically sealed stainless-steel housing and IP67 rating protect against harsh environmental factors, including water immersion, dust, and corrosive gases. This durability ensures reliable performance in offshore platforms, refineries, and other challenging environments.

Easy System Integration: With a standard threaded mount and 2-wire 4–20 mA connectivity, the 135473-01 simplifies installation in existing monitoring systems. Its compatibility with BENTLY’s 3500 Series and third-party data acquisition systems reduces integration complexity and costs.

Low Noise and High Reliability: The built-in signal conditioning and loop-powered design minimize electromagnetic interference, ensuring clean vibration signals. The sensor’s piezoelectric design eliminates moving parts, reducing wear and enhancing long-term reliability.

Wide Operational Range: Capable of operating from -40°C to +121°C, the 135473-01 suits both ambient and high-temperature applications, such as turbine casings and engine compartments. Its shock resistance (1000 g) further ensures durability in high-impact environments.

Application Areas

The BENTLY 135473-01 is essential for vibration monitoring in industries where equipment reliability is critical:

- Oil & Gas: Monitors compressors, pumps, and turbines in refineries, pipelines, and offshore platforms to detect misalignment, bearing wear, or cavitation, preventing costly shutdowns.

- Power Generation: Installed on steam turbines, generators, and auxiliary equipment in thermal and nuclear plants to maintain grid stability and optimize energy production.

- Manufacturing: Used in high-speed rotating machinery like motors, fans, and conveyor systems to ensure production continuity and product quality in automotive, chemical, and food processing facilities.

- Mining: Deployed on crushers, mills, and ventilation systems to monitor equipment health in harsh mining environments, reducing downtime and maintenance costs.

Specific applications include:

- Bearing Condition Monitoring: Detects early signs of bearing degradation by analyzing acceleration waveforms, allowing proactive replacement before catastrophic failure.

- Structural Vibration Analysis: Measures casing vibrations in reciprocating engines to assess structural integrity and prevent fatigue failures.

- Imbalance Detection: Identifies rotational imbalance in turbines and pumps, enabling timely balancing to reduce mechanical stress.

Related Products

- BENTLY 3300 XL 8 mm Proximity Probe: A complementary displacement sensor for measuring shaft position, often used alongside the 135473-01 for comprehensive vibration analysis.

- BENTLY 3500/42M Vibration Monitor: Processes signals from the 135473-01 to provide real-time vibration analysis and alarm triggering.

- BENTLY 3500/22M Keyphasor Module: Supplies rotational reference signals for phase-locked vibration analysis with the 135473-01.

- BENTLY 123M4610 Velocity Transducer: A velocity sensor compatible with the 135473-01 for combined acceleration and velocity monitoring.

- BENTLY 3500/05 Rack Enclosure: Houses vibration monitors and other modules for centralized monitoring with the 135473-01.

- BENTLY 330500 Proximity Probe System: A high-precision displacement sensor suite that integrates with the 135473-01 for comprehensive machinery protection.

Installation and Maintenance

Pre-installation Preparations:

Before installing the BENTLY 135473-01, verify the mounting surface is flat and free of debris. Use a torque wrench to secure the sensor to the equipment (recommended torque: 11–14 N·m) to ensure optimal vibration transfer. Route shielded cables away from high-voltage lines to minimize interference, and connect the sensor to the monitoring system using a 2-wire 4–20 mA configuration. Calibrate the system with a known vibration source to ensure measurement accuracy.

Before installing the BENTLY 135473-01, verify the mounting surface is flat and free of debris. Use a torque wrench to secure the sensor to the equipment (recommended torque: 11–14 N·m) to ensure optimal vibration transfer. Route shielded cables away from high-voltage lines to minimize interference, and connect the sensor to the monitoring system using a 2-wire 4–20 mA configuration. Calibrate the system with a known vibration source to ensure measurement accuracy.

Maintenance Suggestions:

- Routine Inspections: Quarterly visual checks for loose connections, corrosion, or physical damage. Use a handheld vibrometer to compare 135473-01 readings with reference sensors for calibration verification.

- Cleaning: Remove dust and debris from the sensor’s housing using a dry cloth or compressed air, especially in dusty environments. Avoid using solvents that may damage the enclosure.

- Periodic Calibration: Annually calibrate the 135473-01 using a vibration shaker table to maintain measurement accuracy. Document calibration results for compliance and traceability.

- Spare Parts Management: Store spare 135473-01 sensors in a temperature-controlled environment (10–30°C) with low humidity to preserve performance.

Product Guarantee

Our company provides a 12-month quality warranty for the BENTLY 135473-01, covering hardware defects under normal use. In the event of abnormal performance, we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the 135473-01 and related spares. Our technical support team assists with installation, calibration, and troubleshooting, ensuring reliable operation to safeguard your industrial systems.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

BENTLY 125388-01H Analog input

BENTLY 125680-01 Digital output

BENTLY 3500/77M 176449-07 modbus card

BENTLY 3500/54 133396-01 Power strip

BENTLY 3500/32 125720-01 Power source

BENTLY 3500/45 176449-04 base

BENTLY 3500/15 114M5330-01 Network communication

BENTLY 3500/77M 176449-07 Safety system

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: