Description

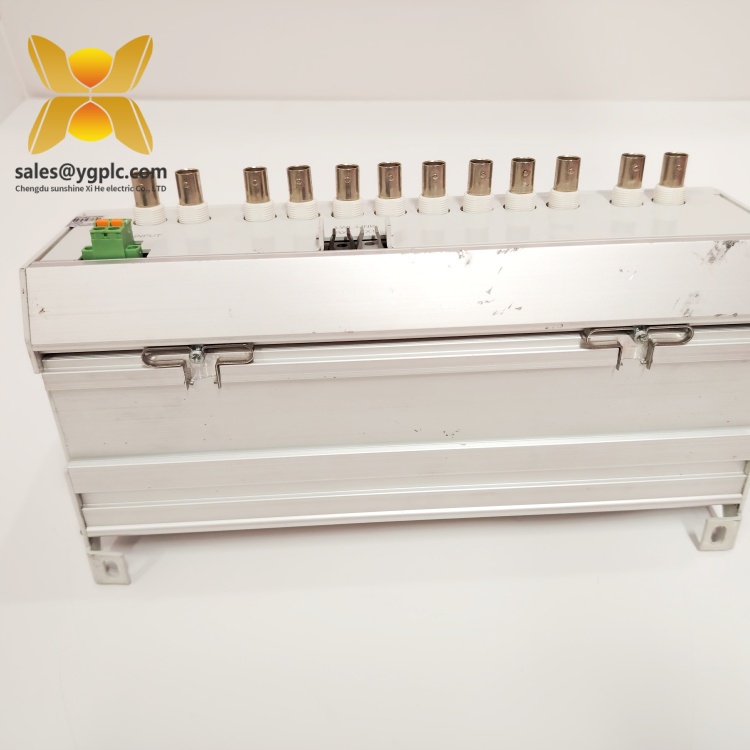

ABB XUD194 3BHE018137R0001 AC800PEC Process Automation Controller

Product Overview:ABB XUD194 3BHE018137R0001 AC800PEC

The ABB XUD194 3BHE018137R0001 AC800PEC process automation controller is a high-performance industrial controller designed as the core of ABB’s AC800PEC series, catering to demanding process automation and machine control applications. Engineered to deliver reliable real-time control, advanced diagnostics, and seamless integration with enterprise systems, this controller serves as a cornerstone in industrial automation architectures, ensuring optimal performance in sectors ranging from power generation to pharmaceutical manufacturing.

As a Programmable Automation Controller (PAC), the XUD194 3BHE018137R0001 AC800PEC combines the robustness of PLCs with the computational power of industrial computers. It supports multiple programming languages (IEC 61131-3) and features a dual-core processor for parallel execution of control logic and data processing tasks. The controller’s modular design allows seamless expansion through ABB’s S800 I/O system, enabling scalability from small-scale machines to large-scale process plants. With its Ethernet/IP and PROFINET connectivity, the AC800PEC integrates effortlessly with SCADA systems, HMIs, and cloud-based analytics platforms, facilitating real-time monitoring and predictive maintenance.

Built to withstand harsh industrial environments, the XUD194 3BHE018137R0001 AC800PEC meets IP20 protection standards and operates reliably across a temperature range of -20°C to +60°C. Its redundant power supply and hot-swappable components minimize downtime, while built-in cybersecurity features (e.g., encrypted communication, secure boot) safeguard against unauthorized access and data breaches. In automation systems, this controller optimizes operational efficiency by enabling precise control of complex processes, reducing energy consumption, and enhancing overall system reliability.

Technical Specifications:ABB XUD194 3BHE018137R0001 AC800PEC

| Parameter Name | Parameter Value |

|---|---|

| Product Model | XUD194 3BHE018137R0001 AC800PEC |

| Manufacturer | ABB |

| Product Type | Process Automation Controller |

| Processor | Dual-core ARM Cortex-A9 @ 800 MHz |

| Memory | 2 GB RAM, 8 GB flash |

| Power Supply | 24V DC (±20%), redundant |

| Communication Protocols | Ethernet/IP, PROFINET, Modbus TCP, CANopen |

| Physical Dimensions | 200 mm (H) × 150 mm (W) × 100 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail (TS35/7.5 or TS35/15) |

| Country of Origin | Switzerland |

ABB XUD194 XUD194A 3BHC018137R0001

Main Features and Advantages:ABB XUD194 3BHE018137R0001 AC800PEC

High-Performance Processing: The XUD194 3BHE018137R0001 AC800PEC leverages a dual-core processor to handle complex control algorithms and data-intensive tasks simultaneously, ensuring minimal cycle times (down to 1 ms) for critical applications. This performance is vital for real-time control in high-speed manufacturing lines or precision machinery.

Modular and Scalable Design: As part of ABB’s AC800PEC ecosystem, the controller supports seamless integration with S800 I/O modules (e.g., analog/digital inputs/outputs, temperature controllers), allowing users to scale systems from 16 to over 1,000 I/O points. Its compact footprint optimizes space in control cabinets, while standardized interfaces simplify installation and upgrades.

Robust Redundancy Features: The controller offers optional hardware redundancy (dual controllers and power supplies) to eliminate single points of failure. In redundant configurations, the AC800PEC ensures uninterrupted operation during module replacement or maintenance, making it suitable for 24/7 production environments like oil refineries or power plants.

Advanced Cybersecurity: Built-in security features include secure boot, encrypted data transmission over PROFINET/Ethernet/IP, and role-based access control, aligning with industry standards like IEC 62443. These measures protect against cyber threats, ensuring compliance with global security regulations in critical infrastructure sectors.

Ease of Integration: The controller is compatible with ABB’s Automation Builder software, which supports drag-and-drop programming, system diagnostics, and firmware updates. Its open communication protocols enable integration with third-party devices, such as variable frequency drives (VFDs) or smart sensors, reducing reliance on proprietary solutions.

ABB XUD194 XUD194A 3BHC018137R0001

Application Areas:ABB XUD194 3BHE018137R0001 AC800PEC

The ABB XUD194 3BHE018137R0001 AC800PEC process automation controller excels in industries requiring precise, reliable, and scalable control solutions:

- Power Generation: Used in gas and steam turbine control systems to manage speed, load, and safety interlocks. The controller’s redundancy features ensure stable power output in utility plants and combined heat and power (CHP) systems.

- Oil and Gas: Deployed in upstream and downstream applications, such as compressor control, pipeline monitoring, and refinery automation. Its rugged design and cybersecurity features meet the harsh environmental and safety requirements of offshore platforms and refineries.

- Manufacturing: Optimizes production lines in automotive, food and beverage, and pharmaceutical industries by controlling robotic arms, conveyor systems, and quality control sensors. The controller’s real-time data processing capabilities enable predictive maintenance and reduce downtime.

- Water and Wastewater Treatment: Manages pump stations, filtration systems, and chemical dosing processes in water treatment plants. Its ability to integrate with SCADA systems ensures compliance with regulatory standards and efficient resource management.

- Mining and Metals: Supports control of crushing plants, smelters, and material handling systems. The controller’s resistance to dust, vibration, and temperature fluctuations makes it suitable for harsh mining environments.

ABB XUD194 XUD194A 3BHC018137R0001

Related Products:ABB XUD194 3BHE018137R0001 AC800PE

- XVC792 3BHE022689R0101 (S800 I/O Module): A digital input module sets with the AC800PEC, providing 32 channels for monitoring binary signals from sensors or switches.

- XVA716 3BHE022641R0101 (S800 I/O Module): An analog output module that interfaces with the controller to regulate actuators or valves, offering 16 channels with 16-bit resolution.

- XPS710 3BHE002805R0101 (Power Supply): A redundant power supply unit designed for the AC800PEC system, ensuring stable 24V DC power delivery with overload protection.

- XUI512 3BHE018136R0001 (Communication Module): Enables PROFINET RT/IRT connectivity, expanding the controller’s network capabilities for high-performance industrial Ethernet applications.

- XUD196 3BHE018138R0001 (AC800PEC Controller): An upgraded version with higher processing power and additional memory, suitable for large-scale automation projects requiring advanced analytics.

- XTA665 3BHE022660R0101 (Temperature Module): Supports RTD/thermocouple inputs, allowing the controller to monitor and control temperature in heating/cooling systems.

- XSB701 3BHE007783R0101 (System Bus Module): Facilitates communication between the AC800PEC and S800 I/O modules, ensuring high-speed data transfer within the control system.

Installation and Maintenance

Pre-installation Preparations:

Before installing the XUD194 3BHE018137R0001 AC800PEC, verify the power supply (24V DC) and ensure the DIN rail is properly grounded. Clean the installation area to remove dust or debris that could affect heat dissipation. Align the controller with the rail and secure it using the provided clips. Connect the power cables to the terminal block, ensuring correct polarity, and establish network connections via Ethernet or PROFINET ports. Use ABB’s Automation Builder software to configure the controller’s IP address and install necessary firmware updates.

Before installing the XUD194 3BHE018137R0001 AC800PEC, verify the power supply (24V DC) and ensure the DIN rail is properly grounded. Clean the installation area to remove dust or debris that could affect heat dissipation. Align the controller with the rail and secure it using the provided clips. Connect the power cables to the terminal block, ensuring correct polarity, and establish network connections via Ethernet or PROFINET ports. Use ABB’s Automation Builder software to configure the controller’s IP address and install necessary firmware updates.

Maintenance Recommendations:

- Routine Inspections: Monthly checks should include verifying power supply voltage, temperature indicators, and network connectivity. Clean the controller’s vents with compressed air to prevent dust accumulation, which can lead to overheating.

- Firmware Updates: Periodically update the controller’s firmware through Automation Builder to access new features, security patches, and compatibility improvements with newer I/O modules or software tools.

- Redundancy Testing: For systems with redundant controllers or power supplies, conduct quarterly tests to ensure failover functionality works seamlessly. Replace faulty components immediately to maintain system reliability.

- Spare Parts Management: Keep critical spares, such as power supplies or communication modules, in stock to minimize downtime. The AC800PEC’s hot-swappable design allows for quick replacement of defective modules without powering down the system.

ABB XUD194 XUD194A 3BHC018137R0001

Product Warranty:ABB XUD194 3BHE018137R0001 AC800PEC

Our company provides a 12-month quality warranty for the **ABB XUD194 3BHE018137R0001 AC800PEC controller, covering non-human-induced hardware defects. If the product experiences performance issues or functional failures during the warranty period, we will promptly replace it to ensure uninterrupted operations. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce components, leveraging partnerships with manufacturers and distributors worldwide.

With 17 years of expertise in industrial control distribution, we offer competitive pricing, technical support, and logistics solutions tailored to meet the unique needs of our clients. Whether troubleshooting configuration issues or providing installation guidance, our team of experts is committed to delivering reliable service that enhances the longevity and performance of your automation systems.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for official technical documentation. Always refer to ABB’s manuals for detailed installation, operation, and safety instructions.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

ABB 3ASC25H208 DATX100 redundancy

ABB 3ASC25H214 DATX130 Network communication

ABB RXIDK 2H 1MRK000838-HA Safety system

ABB REF543KB127AAAA Distributed control

ABB PFEA111-20 3BSE028140R0020 Terminal panel

ABB PFEA111-20 3BSE050090R20 PDP panel

ABB PM511V16 3BSE011181R1 programmable

ABB S-093H 3BHB009885R0004 Logic controller

ABB PFSK152 3BSE018877R1 Control panel

ABB SR511 3BSE000863R0001 Double output

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: