Description

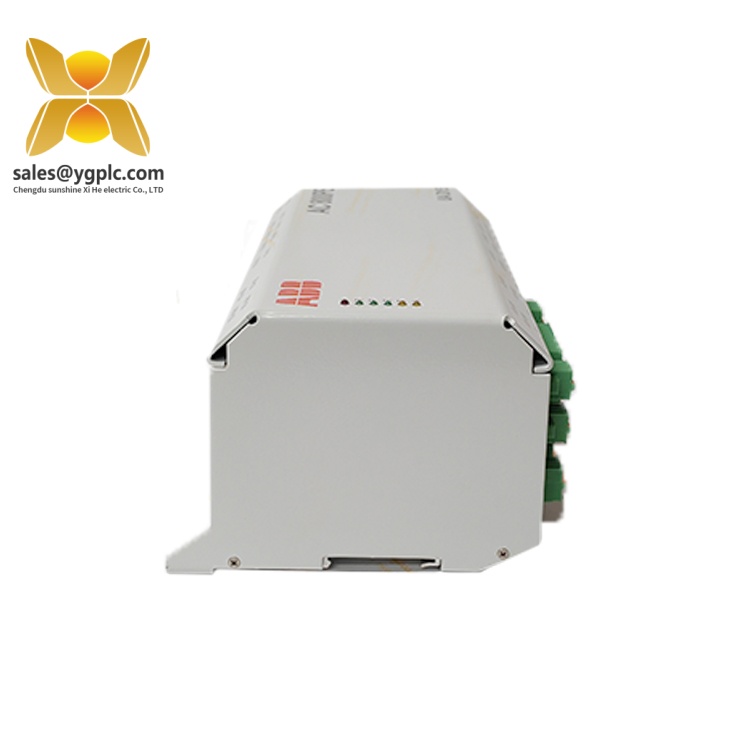

Product Overview:ABB UAD155A0111 3BHE029110R0111

Technical Specifications:ABB UAD155A0111 3BHE029110R0111

| Parameter Name | Parameter Value |

|---|---|

| Product Model | UAD155A0111 3BHE029110R0111 |

| Manufacturer | ABB |

| Product Type | Digital Input Module |

| Input Channels | 16 isolated channels |

| Input Voltage | 24–230 V AC/DC |

| Signal Type | Discrete (binary) |

| Response Time | ≤10 ms |

| Isolation | Galvanic isolation (2.5 kV RMS) |

| Power Supply | 24 V DC ±10% (redundant) |

| Physical Dimensions | 100 mm (H) × 160 mm (W) × 60 mm (D) |

| Weight | 0.6 kg |

| Operating Temperature | -25°C to +70°C |

| Mounting | DIN rail (35 mm) |

| Certifications | CE, UL, IEC 61131-2 |

UAD155A0111 3BHE029110R0111

Key Features and Advantages

Seamless Integration: As part of ABB’s S800 I/O system, the module interoperates seamlessly with other ABB components (e.g., AI modules, communication gateways) and third-party systems via open protocols like MODBUS. This interoperability enhances system scalability and flexibility.

UAD155A0111 3BHE029110R0111

Application Areas:ABB UAD155A0111 3BHE029110R0111

- Oil & Gas: Monitoring valve positions, pump status, and safety interlocks in offshore platforms, refineries, and pipelines to ensure compliance with safety standards and prevent operational disruptions.

- Power Generation: Controlling turbine startup/shutdown sequences, monitoring generator breaker states, and managing auxiliary systems in thermal, hydro, and nuclear power plants.

- Manufacturing: Tracking conveyor belt alignment, detecting equipment faults in assembly lines, and managing robotic systems in automotive, chemical, and food processing facilities.

- Water/Wastewater: Monitoring pump status, valve positions, and level switches in treatment plants to optimize process efficiency and ensure regulatory compliance.

- Safety Instrumented Systems (SIS): Providing fail-safe input signals for emergency shutdown systems, ensuring rapid response to critical events.

- Machine Control: Converting sensor inputs (e.g., limit switches, proximity sensors) into digital commands for PLCs, enabling precise automation of manufacturing processes.

- Condition Monitoring: Integrating with vibration sensors and temperature switches to detect early signs of equipment degradation, facilitating predictive maintenance.

Related Products:ABB UAD155A0111 3BHE029110R0111

- UAD165A0111 3BHE029111R0111: A 32-channel digital input module with higher channel density, suitable for applications requiring large-scale signal monitoring.

- UAD153A0111 3BHE029108R0111: A compact 8-channel module optimized for space-constrained environments, ideal for small-scale automation systems.

- UDA150A0111 3BHE029101R0111: A universal input module supporting both analog and discrete signals, offering flexibility for mixed-signal applications.

- SD822Z Power Supply: A redundant 24 V DC power supply designed to support S800 I/O modules, ensuring uninterrupted operation.

- CI853K01 Communication Module: Enables integration of the UAD155A0111 3BHE029110R0111 with PLCs or DCS systems via Profibus DP or Ethernet/IP.

- TB840A Module Bus Cluster Modem: Provides optical communication for long-distance signal transmission, extending the module’s reach in distributed control systems.

- PM856K01 Controller Module: A high-performance PLC controller that pairs with the UAD155A0111 3BHE029110R0111 for advanced process automation.

- TU841 Termination Unit: Simplifies field wiring by providing a centralized connection point for input signals, reducing installation complexity.

UAD155A0111 3BHE029110R0111

Installation and Maintenance:ABB UAD155A0111 3BHE029110R0111

Before installing the ABB UAD155A0111 3BHE029110R0111, ensure the DIN rail is securely mounted and grounded. Verify compatibility with existing field devices and cabling, using shielded wires to minimize electromagnetic interference. Connect the module’s redundant 24 V DC power supply and configure input parameters (e.g., voltage type, filter settings) using ABB’s S800 I/O Configuration Tool. Mount the module vertically within the control panel, leaving sufficient space for heat dissipation.

- Routine Checks: Inspect the module quarterly for loose connections, corrosion, or physical damage. Clean the enclosure with a dry cloth to prevent dust accumulation.

- Calibration: Perform annual calibration using ABB’s diagnostic tools to ensure accurate signal detection. Document calibration results for compliance audits.

- Firmware Updates: Periodically update the module’s firmware to access new features and security patches, following ABB’s official guidelines.

- Spare Parts Management: Maintain a spare UAD155A0111 3BHE029110R0111 module in a controlled environment (temperature: 10–30°C, humidity: 20–80% RH) to minimize downtime in case of failure.

UAD155A0111 3BHE029110R0111

Product Warranty:ABB UAD155A0111 3BHE029110R0111

For inquiries, contact our dedicated team via Whatsapp:+86 18859254943 or E-mail :sales@ygplc.com.

ABB AO2000 LS25 I/O fault diagnosis

ABB SCYC51020 58052582/G DCS module

ABB PCD530A102 3BHE041343R0102 Servo valve

ABB PCD235C101 3BHE057901R0101 Analog input

ABB 086329-004 Servo module

ABB 086348-001 Control cabinet node unit

ABB 086370-001 governor

ABB 086444-005 Input module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: