Description

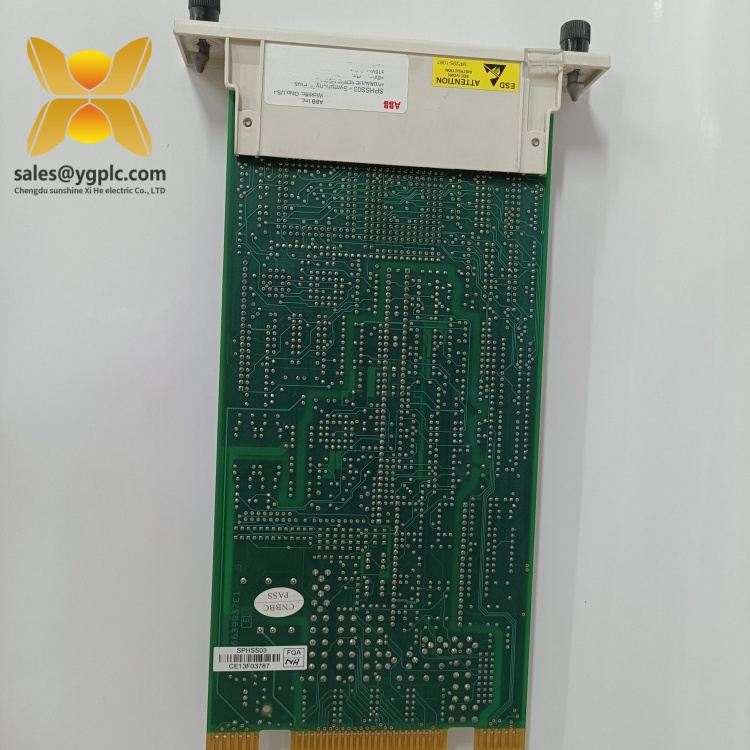

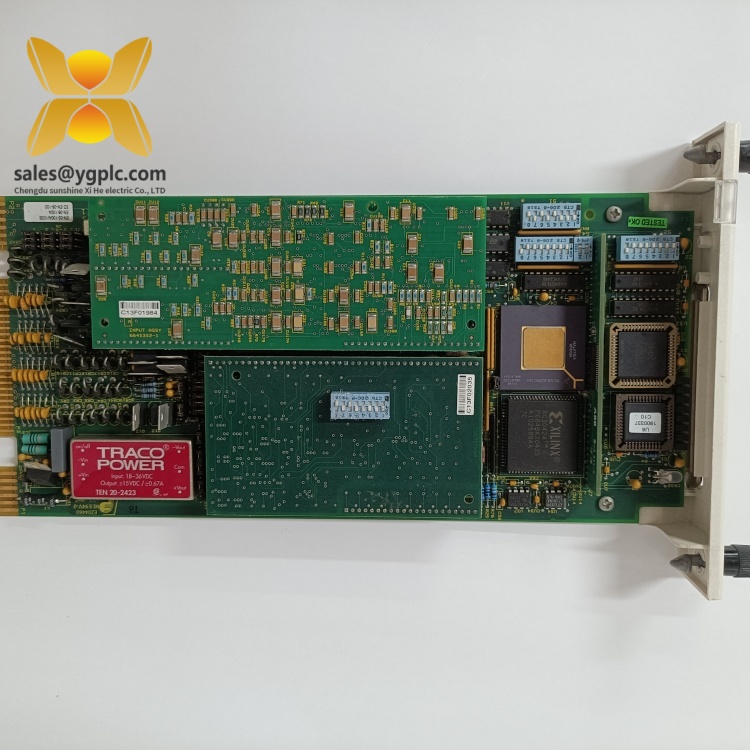

Product Overview: ABB SPHSS13

In the dynamic landscape of industrial automation, precision, reliability, and efficiency are not just requirements—they are the foundation of operational success. ABB, a global leader in power and automation technologies, has consistently delivered innovative solutions that redefine industry standards. The ABB SPHSS13 stands as a testament to this legacy, engineered to meet the rigorous demands of modern industrial systems while ensuring seamless integration and long-term performance.

Designed as a critical component in ABB’s extensive portfolio of automation solutions, the ABB SPHSS13 serves as a high-performance interface module, bridging gaps between various system components to enhance communication, reduce latency, and optimize overall operational flow. Whether deployed in manufacturing plants, energy facilities, or process industries, this module is built to withstand harsh environmental conditions, including extreme temperatures, vibration, and electrical interference—factors that often compromise lesser components.

What sets the ABB SPHSS13 apart is its blend of advanced technology and user-centric design. ABB’s decades of expertise in industrial automation have informed every aspect of its development, from material selection to software integration, ensuring that it not only meets but exceeds industry certifications and compliance standards. For engineers, system integrators, and plant managers, the ABB SPHSS13 represents more than a component—it is a reliable partner in maintaining uninterrupted operations, minimizing downtime, and maximizing productivity.

Technical Specifications — ABB SPHSS13

| Parameter | Specification |

|---|---|

| Model | ABB SPHSS13 |

| Operating Voltage | 24 V DC ±10% |

| Power Consumption | ≤5 W (typical) |

| Operating Temperature | -25°C to +70°C (-13°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Communication Protocol | Profibus DP, Modbus RTU |

| Input/Output Channels | 8 digital inputs, 4 digital outputs |

| Response Time | ≤10 ms (input to output) |

| Protection Rating | IP20 (front panel), IP40 (enclosure) |

| Dimensions (W×H×D) | 45mm × 120mm × 110mm |

| Weight | Approx. 200g |

| Certifications | CE, UL, ATEX, IECEx |

| Mounting Type | DIN rail (35mm) |

ABB SPHSS13

Related products: ABB SPHSS13

The ABB SPHSS13 is part of ABB’s comprehensive range of automation components, designed to work in harmony with other trusted products to create fully integrated systems. For users seeking complementary solutions, consider these related ABB models:

- ABB SPHSS11: A compact interface module with reduced I/O channels, ideal for smaller-scale applications requiring the same reliability as the ABB SPHSS13.

- ABB SPHSS23: A high-density variant with expanded communication protocols, suitable for complex industrial networks.

- ABB CI854A: A communication interface unit that enhances data exchange between the ABB SPHSS13 and higher-level control systems.

All these products, like the ABB SPHSS13, adhere to ABB’s strict quality standards, ensuring interoperability and consistent performance across your automation ecosystem.

Main features and advantages: ABB SPHSS13

The ABB SPHSS13 is engineered to deliver tangible benefits to industrial operations, combining cutting-edge features with practical advantages that translate to improved efficiency and reduced costs.

-

Dual Protocol Support: With native compatibility for Profibus DP and Modbus RTU, the ABB SPHSS13 seamlessly integrates with legacy and modern systems alike. This flexibility eliminates the need for additional converters, simplifying setup and reducing potential points of failure.

-

Robust Environmental Resistance: Tested to perform in extreme conditions, the ABB SPHSS13 operates reliably in temperatures ranging from -25°C to +70°C. Its rugged enclosure protects against dust, vibration, and electrical noise, making it suitable for harsh industrial environments such as steel mills, chemical plants, and outdoor energy facilities.

-

High-Speed Response: With a response time of ≤10 ms, the ABB SPHSS13 ensures real-time data transmission between connected devices. This speed is critical in time-sensitive applications, such as assembly line robotics or power grid management, where delays can lead to costly disruptions.

-

Simplified Installation: Designed for DIN rail mounting, the ABB SPHSS13 can be installed quickly without specialized tools. Its compact dimensions (45mm width) save space in control cabinets, allowing for more efficient use of limited space in industrial setups.

-

Comprehensive Certifications: The ABB SPHSS13 meets global safety and performance standards, including CE, UL, ATEX, and IECEx. This compliance ensures it can be deployed in hazardous areas and international markets without additional modifications, reducing regulatory hurdles for multi-site operations.

-

Energy Efficiency: Consuming ≤5 W of power under typical conditions, the ABB SPHSS13 contributes to lower energy costs compared to bulkier, less efficient alternatives. This energy efficiency aligns with modern industrial goals of reducing carbon footprints and operating sustainably.

ABB SPHSS13

Installation and maintenance: ABB SPHSS13

Installing and maintaining the ABB SPHSS13 is designed to be straightforward, minimizing downtime and ensuring long-term reliability.

Installation Steps:

- Mounting: Secure the ABB SPHSS13 on a standard 35mm DIN rail in a control cabinet, ensuring adequate ventilation (maintain a 50mm gap between adjacent components).

- Wiring: Connect power (24 V DC) and communication cables (Profibus DP or Modbus RTU) to the terminal blocks, following the labeling on the front panel for polarity and pin assignments.

- Configuration: Use ABB’s Engineering Tool software to set communication parameters (baud rate, address) via the module’s built-in interface. Default settings are pre-loaded for quick setup in standard applications.

- Testing: Power on the system and verify communication with connected devices using the tool’s diagnostic features. The ABB SPHSS13 includes LED indicators for power, communication status, and fault alerts to simplify troubleshooting.

Maintenance Guidelines:

- Regular Inspections: Check connections quarterly for tightness and signs of corrosion, especially in humid or dusty environments.

- Software Updates: Periodically update the module’s firmware via ABB’s official portal to access new features and performance improvements.

- Replacement Parts: Spare terminal blocks and fuses are available through ABB’s global supply chain, ensuring quick replacements if needed.

The ABB SPHSS13 is designed for minimal maintenance, with a mean time between failures (MTBF) exceeding 100,000 hours, ensuring years of reliable operation with basic upkeep.

ABB SPHSS13

Application fields: ABB SPHSS13

The versatility of the ABB SPHSS13 makes it a valuable asset across diverse industrial sectors, where reliable communication and robust performance are critical.

-

Manufacturing: In automotive and electronics production lines, the ABB SPHSS13 connects sensors, actuators, and PLCs, enabling precise control of assembly robots and conveyor systems. Its fast response time ensures synchronization between processes, reducing waste and improving product quality.

-

Energy Sector: In power plants and renewable energy facilities (solar, wind), the ABB SPHSS13 monitors and controls switchgear, transformers, and grid components. Its ability to operate in wide temperature ranges makes it suitable for outdoor substations and remote installations.

-

Chemical Processing: In facilities handling hazardous materials, the ABB SPHSS13’s ATEX and IECEx certifications ensure safe operation in explosive environments. It facilitates communication between batch controllers and valves, maintaining precise control over chemical reactions.

-

Water and Wastewater Treatment: The module’s resistance to moisture and dust makes it ideal for water treatment plants, where it connects level sensors, pumps, and filtration systems. Its reliable performance helps prevent overflows and ensures consistent water quality.

-

Mining: In underground and surface mining operations, the ABB SPHSS13 withstands vibration and electrical noise, connecting drilling equipment, conveyor belts, and safety systems to central control rooms, enhancing operational safety and efficiency.

Product guarantee: ABB SPHSS13

ABB stands behind the quality and performance of the ABB SPHSS13 with a comprehensive warranty and support package, ensuring peace of mind for users.

-

Warranty Coverage: The ABB SPHSS13 comes with a 2-year standard warranty, covering defects in materials and workmanship. Extended warranties (up to 5 years) are available for purchase, providing additional protection for long-term projects.

-

Global Support Network: ABB’s network of technical experts and service centers spans over 100 countries, offering 24/7 assistance for installation, troubleshooting, and repairs. Users can access remote diagnostics via ABB’s digital platforms, minimizing on-site service delays.

-

Genuine Replacement Parts: All replacement components for the ABB SPHSS13 are genuine ABB parts, ensuring compatibility and maintaining the module’s performance specifications. Counterfeit parts are strictly prohibited, and ABB provides tools to verify authenticity.

-

Compliance and Traceability: Each ABB SPHSS13 is serialized and comes with a certificate of conformity, ensuring full traceability from manufacturing to delivery. This documentation simplifies audits and regulatory compliance for users in highly regulated industries.

For inquiries about the ABB SPHSS13, including pricing, availability, or technical support, please contact us:

- Email: sales@ygplc.com

- Phone: +86 592 555 8888

- WhatsApp +86 18859254943

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: