Description

ABB S-093H 3BHB009885R0004 Process Automation Controller

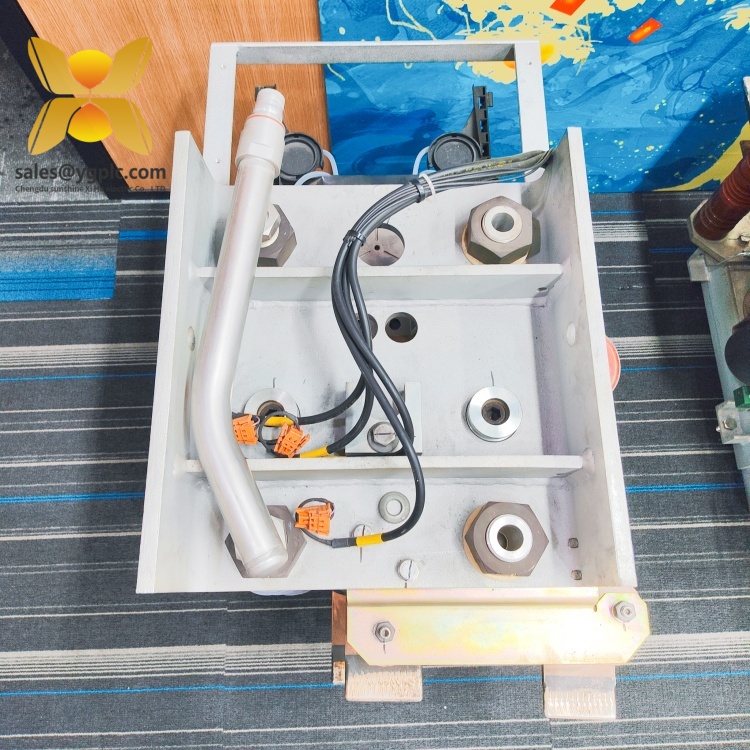

Product Overview :ABB S-093H 3BHB009885R0004

The ABB S-093H 3BHB009885R0004 process automation controller is a high-performance industrial control system designed to manage complex automation tasks in critical infrastructure and manufacturing environments. As part of ABB’s AC 800M series, this controller combines advanced processing capabilities with robust connectivity, making it a cornerstone for real-time control, data acquisition, and supervisory functions in distributed control systems (DCS).

Engineered for scalability and reliability, the S-093H 3BHB009885R0004 features a 32-bit RISC processor and 1 GB RAM, enabling it to handle up to 10,000 I/O points with sub-millisecond response times. Its dual redundant Ethernet interfaces (10/100/1000 Mbps) support seamless integration with ABB’s Control Builder M software and third-party systems via protocols like Modbus TCP, Profibus DP, and OPC UA. The controller’s IP20-rated metal enclosure ensures durability in harsh industrial settings, while its -20°C to +60°C operating temperature range guarantees consistent performance across diverse applications.

In automation systems, the S-093H 3BHB009885R0004 serves as the central processing unit for managing workflows in industries such as oil & gas, power generation, and water treatment. It supports hot-swappable redundancy, allowing for maintenance without system downtime, and features built-in cybersecurity measures to protect against unauthorized access. By delivering precise control and real-time data analytics, this controller enhances operational efficiency, reduces energy consumption, and minimizes the risk of production disruptions.

Technical Specifications :ABB S-093H 3BHB009885R0004

| Parameter Name | Parameter Value |

|---|---|

| Product Model | S-093H 3BHB009885R0004 |

| Manufacturer | ABB |

| Product Type | Process Automation Controller |

| Processor | 32-bit RISC, 800 MHz |

| Memory | 1 GB RAM, 2 GB Flash |

| I/O Capacity | Up to 10,000 points |

| Communication Interfaces | 2 x Ethernet (10/100/1000 Mbps), 2 x RS485 |

| Communication Protocols | Modbus TCP, Profibus DP, OPC UA, CANopen |

| Physical Dimensions | 220 mm x 150 mm x 100 mm |

| Weight | 2.3 kg |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail (TS35/7.5) |

| Country of Origin | Sweden |

ABB S-093H 3BHB009885R0004

Key Features and Advantages :ABB S-093H 3BHB009885R0004

High-Speed Processing: The S-093H 3BHB009885R0004’s 800 MHz RISC processor and optimized firmware enable rapid execution of control algorithms, making it suitable for applications requiring real-time decision-making, such as high-speed packaging lines or power grid stabilization.

Redundancy and Reliability: With support for dual controller redundancy, the module ensures continuous operation even during component failure. Its error-correcting code (ECC) memory and built-in watchdog timer further enhance system stability in mission-critical environments.

Scalable Architecture: The controller’s modular design allows for easy expansion via ABB’s S800 I/O modules, accommodating up to 64 racks in a single network. This scalability makes it ideal for both small-scale automation projects and large industrial complexes.

Advanced Cybersecurity: Equipped with role-based access control and encrypted communication channels, the S-093H 3BHB009885R0004 complies with international cybersecurity standards (IEC 62443), protecting against cyber threats in connected industrial systems.

Energy Efficiency: The controller’s low-power design (25W typical consumption) reduces operational costs and aligns with sustainability goals, making it suitable for energy-intensive industries like chemical processing and metal refining.

Application Areas :ABB S-093H 3BHB009885R0004

The ABB S-093H 3BHB009885R0004 process automation controller is widely deployed in industries demanding high precision and reliability:

- Oil & Gas: Manages upstream wellhead control, midstream pipeline monitoring, and downstream refinery processes. For example, in a liquefied natural gas (LNG) plant, the controller optimizes compressor performance while ensuring compliance with safety protocols.

- Power Generation: Controls steam turbines, gas engines, and renewable energy systems. In a combined cycle power plant, the S-093H 3BHB009885R0004 coordinates fuel supply and exhaust management to maximize energy output.

- Water and Wastewater: Oversees pump stations, treatment reactors, and distribution networks. In a municipal water plant, it monitors flow rates, chemical dosing, and quality parameters to ensure regulatory compliance.

- Manufacturing: Optimizes production lines in automotive, food & beverage, and pharmaceutical sectors. For instance, in a pharmaceutical facility, the controller manages sterile filling processes while maintaining traceability and batch records.

- Mining: Controls conveyor systems, ventilation networks, and mineral processing equipment. In an underground mine, it integrates with safety systems to monitor gas levels and automate emergency shutdowns.

ABB S-093H 3BHB009885R0004

Related Products :ABB S-093H 3BHB009885R0004

- ABB S-094H 3BHB009886R0001: An upgraded version with 2 GB RAM and support for real-time data analytics, ideal for AI-driven predictive maintenance applications.

- ABB S800 I/O Modules (e.g., 3BHB005519R0101): Complementary I/O modules that expand the controller’s analog/digital input/output capabilities for the AC 800M series.

- ABB PM866AK01 3BSE018285R1: A legacy controller in the AC 800M family, suitable for retrofitting older systems while maintaining compatibility with the S-093H.

- ABB CI854A 3BHB002818R0101: A Profibus DP communication interface module that enhances the controller’s connectivity with field devices in distributed setups.

- ABB TB821 3BHB002056R0101: A terminal block module that simplifies wiring and maintenance for the S-093H 3BHB009885R0004 in harsh industrial environments.

- ABB PS501 3BHB002030R0101: A redundant power supply module that ensures stable operation of the controller in unstable power conditions.

- ABB CP604 3BHB002118R0101: A compact panel controller that works alongside the S-093H for local HMI integration in small-scale automation systems.

Installation and Maintenance :ABB S-093H 3BHB009885R0004

Pre-installation Preparation:

Before installing the S-093H 3BHB009885R0004, verify the 24V DC power supply and ensure the DIN rail is securely mounted in a grounded control cabinet. Clean the rail and check for compatibility with ABB’s AC 800M software tools (e.g., Control Builder M). Align the controller with the rail, secure it with mounting brackets, and connect power cables using the terminal block. Configure network settings via the controller’s web interface or Control Builder M, ensuring IP addresses match the automation network’s schema.

Before installing the S-093H 3BHB009885R0004, verify the 24V DC power supply and ensure the DIN rail is securely mounted in a grounded control cabinet. Clean the rail and check for compatibility with ABB’s AC 800M software tools (e.g., Control Builder M). Align the controller with the rail, secure it with mounting brackets, and connect power cables using the terminal block. Configure network settings via the controller’s web interface or Control Builder M, ensuring IP addresses match the automation network’s schema.

Maintenance Recommendations:

- Routine Checks: Monthly inspect the controller’s status LEDs for error codes and ensure proper ventilation to prevent overheating. Clean dust from the enclosure using a static-free cloth.

- Firmware Updates: Quarterly review ABB’s official support portal for firmware updates, which may include security patches or performance enhancements. Use Control Builder M to deploy updates during scheduled downtime.

- Redundancy Testing: Semi-annually test the controller’s hot-swappable redundancy by simulating a failure in the primary unit to ensure seamless failover to the backup.

- Component Replacement: If replacing faulty components, use only ABB-certified spare parts and follow anti-static procedures. Document all configuration changes to facilitate post-maintenance validation.

ABB S-093H 3BHB009885R0004

Product Guarantee :ABB S-093H 3BHB009885R0004

Our company offers a 12-month quality warranty for the ABB S-093H 3BHB009885R0004 process automation controller, covering non-human-induced hardware defects. In the event of performance anomalies or functional failures during the warranty period, we provide prompt replacement services. For discontinued models or urgent requirements, our global supply chain network—backed by 17 years of industry expertise—enables rapid fulfillment of scarce components. We also offer dedicated technical support to assist with installation, configuration, and troubleshooting, ensuring your industrial systems operate at peak efficiency.

Contact Information:

WhatsApp: +86 18859254943

Email: sales@ygplc.com

WhatsApp: +86 18859254943

Email: sales@ygplc.com

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not substitute for official technical documentation. Always refer to ABB’s product manuals for detailed specifications and safety guidelines.

ABB PPD113B01-10-150000 3BHE023784R0123 transformer

ABB RXIDK 2H 1MRK000838-HA Digital output module

ABB REF543KB127AAAA Control system power supply

ABB PFEA111-20 3BSE028140R0020 Pressure transmitter

ABB PFEA111-20 3BSE050090R20 Main frame

ABB PM511V16 3BSE011181R1 Expansion rack

ABB 3BHE023784R2530 PPD113B01-25-111000 Control panel

ABB 3BHE032025R0101 PCD235A101 Double output

ABB PM866 Acquisition card

ABB PM864AK01 3BSE018161R1 Gas turbine card

ABB GJR5252300R3101 07AC91F FIM card

ABB TVOC-2-240 1SFA664001R1001 Communication input interface component

ABB 07KT92 CS31 rack

ABB AC900F PM904F 3BDH001002R0001 AI/AO/DI/DO module

ABB G2000A5.7ST RXM rack

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: