Description

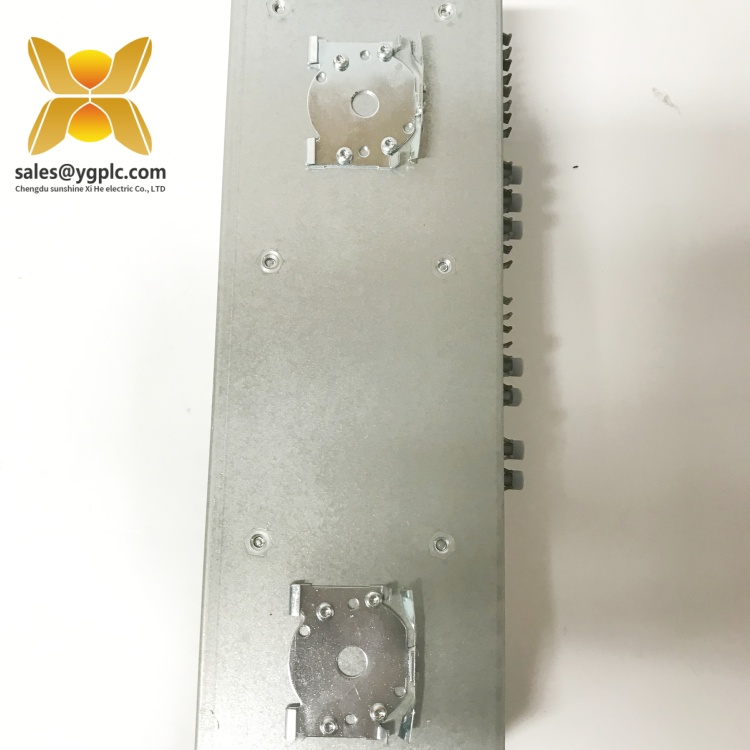

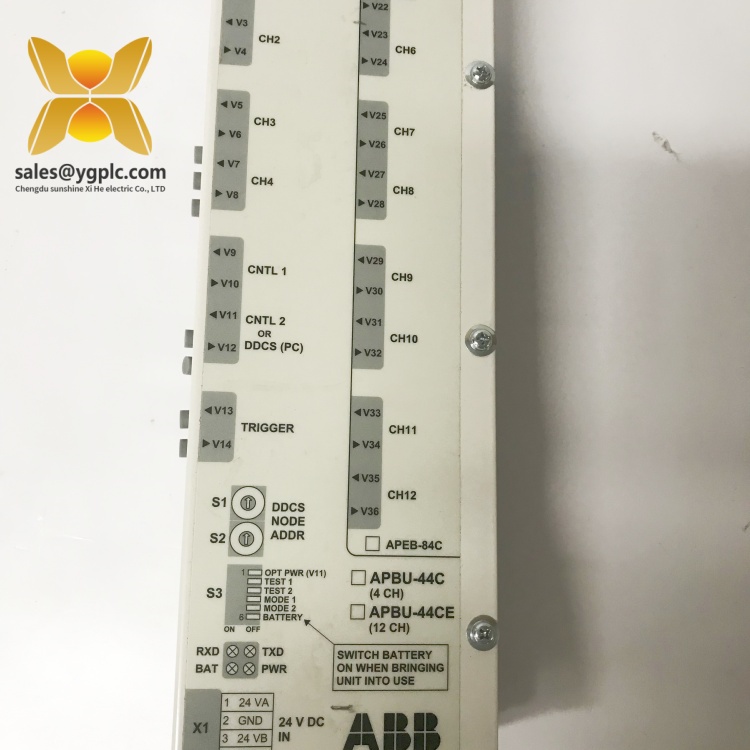

Product Overview:ABB APBU-44C 64669982

Technical Specifications:ABB APBU-44C 64669982

| Parameter Name | Parameter Value |

|---|---|

| Product Model | APBU-44C 64669982 |

| Manufacturer | ABB |

| Product Type | Power Supply Module |

| Input Voltage | 100–240V AC (via external adapter) |

| Output Voltage | 24V DC ±5% |

| Output Current | 4A continuous |

| Physical Dimensions | 100mm x 100mm x 50mm |

| Weight | 0.6 kg |

| Mounting Type | DIN rail (TS 35/7.5 or TS 35/15) |

| Operating Temperature | -25°C to +70°C |

| Humidity | 5–95% non-condensing |

| Redundancy Support | Dual module redundancy |

| Diagnostic Features | LED indicators for power, fault, and battery |

APBU-44C 64669982

Key Features and Advantages:ABB APBU-44C 64669982

Redundancy for Critical Systems: The support for dual-module redundancy ensures that power supply failures do not disrupt system operation. In redundant configurations, the APBU-44C 64669982 automatically takes over if the primary module fails, maintaining continuous power to the PLC and connected devices.

APBU-44C 64669982

Application Areas:ABB APBU-44C 64669982

- Manufacturing Automation: Powers PLCs, HMIs, and robotic systems in automotive assembly lines, food processing plants, and electronics manufacturing facilities. Its redundancy support ensures continuous operation during scheduled maintenance or unexpected power disruptions.

- Energy and Utilities: Used in power plants, substations, and renewable energy systems to maintain control over generators, switchgear, and monitoring systems. The module’s wide temperature range makes it suitable for both indoor and outdoor applications in these sectors.

- Process Control: Supports continuous operation in chemical, petrochemical, and pharmaceutical plants, where stable power is essential for maintaining precise process parameters and ensuring compliance with safety regulations.

- Transportation Infrastructure: Installed in railway signaling systems, airport baggage handling systems, and traffic control centers to prevent downtime caused by power fluctuations or outages.

- Mining and Heavy Industry: Provides reliable power to control systems in mining operations, including conveyor belts, ventilation systems, and crushing equipment, even in harsh underground or outdoor environments.

Related Products

- ABB APBU-44 64669981: A base model in the APBU series with similar dimensions and mounting but a lower output current (2A), suitable for smaller-scale systems.

- ABB APBU-44R 64669983: A redundant version of the module designed for high-availability systems, featuring enhanced fault detection and automatic failover capabilities.

- ABB AC500-ECO PM590-ETH: A PLC processor module that pairs with the APBU-44C 64669982 to form a complete control system, supporting Ethernet communication and advanced programming.

- ABB TB521 Terminal Block: A DIN rail-mounted terminal block for connecting power cables to the APBU-44C 64669982, ensuring secure and reliable wiring.

- ABB BU501 Backup Battery Unit: A compatible battery module that provides backup power for the APBU-44C 64669982, extending runtime during mains failures.

- ABB APBU-44D 64669984: A variant with digital input/output interfaces for integrating with supervisory control systems, enabling remote monitoring of power status.

- ABB S800 I/O Modules: A range of input/output modules that rely on the APBU-44C 64669982 for power, including analog, digital, and temperature measurement modules.

APBU-44C 64669982

Installation and Maintenance:ABB APBU-44C 64669982

Before installing the APBU-44C 64669982, ensure the DIN rail is securely mounted and grounded. Verify that the input voltage (100–240V AC) matches the external power adapter specifications. Connect the primary power cable to the module’s AC input terminals and the DC output cables to the PLC or I/O modules, following ABB’s wiring diagrams. For redundant setups, install a second APBU-44C 64669982 in parallel and configure the redundancy settings using ABB’s Control Builder M software.

- Routine Inspections: Monthly check the module’s LED indicators to ensure proper power status and battery health. Clean the module’s surface with a dry cloth to remove dust, which can affect heat dissipation.

- Battery Replacement: Replace the backup battery (if installed) every 3–5 years or as indicated by the fault LED, using only ABB-approved replacement units to maintain compatibility and performance.

- Firmware Updates: Periodically update the module’s firmware via ABB’s software tools to access the latest features and security patches, ensuring optimal performance and compatibility with other system components.

- Redundancy Testing: Quarterly test the dual-module redundancy by simulating a primary module failure to ensure the backup module activates correctly. Document test results and address any issues promptly.

Product Warranty:ABB APBU-44C 64669982

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not constitute an official technical manual. Always refer to the manufacturer’s documentation for detailed specifications and installation guidelines.

ABB 500AIM02 1MRB150022 R0002Y 1HDF 930412 X010 Control processor

ABB DSAI130A 3BSE018292R1 regulator

ABB 3BHE023784R2530 PPD113B01-25-111000 redundancy

ABB 3BHE032025R0101 PCD235A101 Network communication

ABB KUC720AE01 3BHB003431R0001 3BHB000652R0001 I/O board

ABB SC520 3BSE003816R1 Control panel

ABB SCYC51020 58052582/G Digital input terminal board

ABB CI570 3BSE001440R1 Connecting module

ABB PFSA140 3BSE006503R1 Network communication

ABB 5SHX1960L0004 Safety system

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: