Description

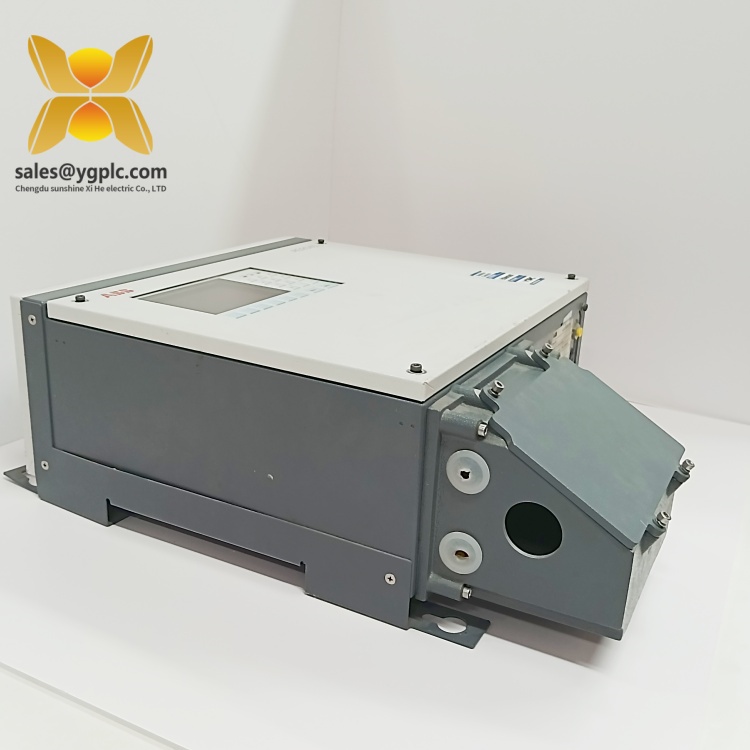

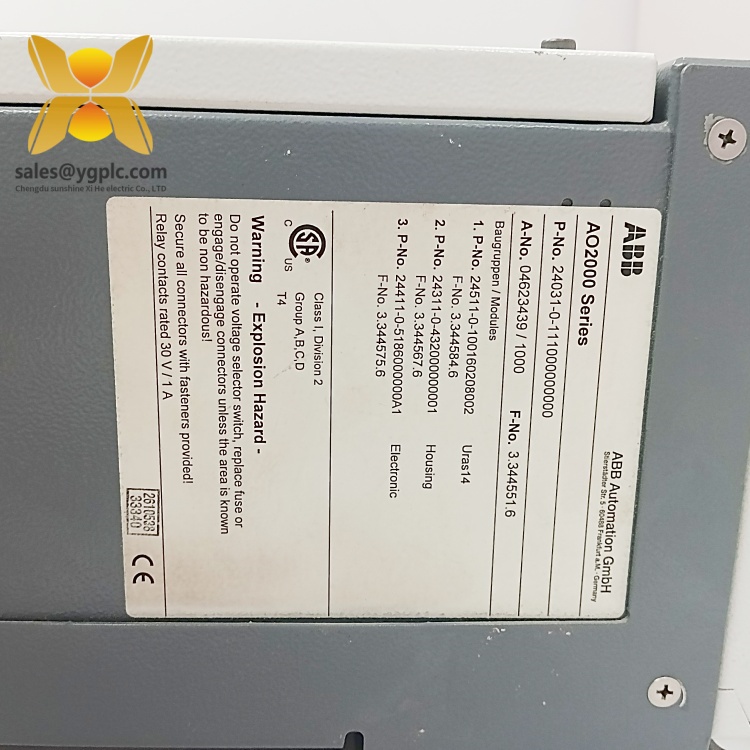

ABB AO2040 Analog Output Module

Product Overview

The ABB AO2040 is a high-precision Analog Output Module designed for industrial automation systems, serving as a critical interface between control systems and field devices that require continuous signal regulation. As part of ABB’s AC 800M controller platform within the Industrial IT System 800xA architecture, this module enables the conversion of digital control signals into analog outputs (4–20 mA or 0–10 V) to manage actuators, valves, variable frequency drives (VFDs), and other analog-dependent equipment. The AO2040 is engineered to deliver reliable performance in harsh industrial environments, making it indispensable for process control applications in industries such as oil & gas, chemical processing, and power generation.

Featuring 4 independent output channels, the ABB AO2040 supports simultaneous control of multiple processes with configurable signal ranges and diagnostic capabilities. Each channel includes short-circuit and overload protection, ensuring robust operation even in the event of transient faults. The module’s hot-swappable design allows for maintenance without powering down the system, minimizing downtime in critical operations. Compatibility with ABB’s S800 I/O system ensures seamless integration with other modules (e.g., analog inputs, digital I/O) and the AC 800M controller, creating a cohesive automation ecosystem.

In industrial control networks, the AO2040 acts as a bridge between the distributed control system (DCS) and field-level devices, ensuring precise adjustment of process parameters like flow rate, pressure, and temperature. Its advanced self-diagnostics continuously monitor output integrity, triggering alarms for signal deviations or module failures. With a compact form factor and DIN rail mounting, the module optimizes space in control panels while adhering to industry standards such as IEC 61131-2, making it a versatile choice for both new installations and retrofitting existing systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | AO2040 |

| Manufacturer | ABB |

| Product Type | Analog Output Module |

| Platform | AC 800M, Industrial IT System 800xA |

| Output Channels | 4 isolated channels |

| Output Signal Range | 4–20 mA (current), 0–10 V (voltage) |

| Resolution | 14 bits |

| Update Time | ≤5 ms |

| Isolation | Galvanic isolation (500 V DC between channels and system) |

| Power Supply | 24 V DC ±20% (via S800 I/O bus) |

| Physical Dimensions | 100 mm (H) × 160 mm (W) × 60 mm (D) |

| Weight | 0.4 kg |

| Operating Temperature | -25°C to +70°C |

| Mounting | DIN rail (35 mm) |

| Certifications | CE, UL, IEC 61000-6-2/6-3 |

ABB AO2040

Key Features and Advantages

High Precision and Reliability: The AO2040 offers 14-bit resolution for both current and voltage outputs, ensuring accurate control of process variables with minimal error (±0.1% of full scale). Galvanic isolation between channels and the system protects against ground loops and electrical noise, enhancing signal integrity in high-interference environments.

Redundant and Hot-Swappable Design: The module supports redundant power supplies and can be replaced while the system is operational, reducing downtime during maintenance. This feature is critical for continuous processes where interruptions could lead to safety hazards or production losses.

Flexible Configuration: Users can configure each channel for current or voltage output via ABB’s Control Builder M software, allowing adaptation to diverse field devices without hardware reconfiguration. Adjustable ramp rates and fail-safe outputs (e.g., last value, safe value) provide additional control over process stability.

Comprehensive Diagnostics: Built-in diagnostics monitor channel status, power supply health, and communication with the controller. LED indicators provide real-time feedback on output status, while fault messages are transmitted to the DCS for centralized monitoring, enabling rapid troubleshooting.

Space-Efficient Design: With dimensions of 100 mm × 160 mm × 60 mm, the AO2040 occupies minimal space in control cabinets, making it suitable for compact automation setups. Its lightweight design (0.4 kg) and standardized DIN rail mounting simplify installation and reduce cabling complexity.

Scalable Integration: As part of the S800 I/O family, the module can be combined with other ABB I/O modules (e.g., AI, DI/DO) and controllers to build scalable systems, from small-scale PLC applications to large-scale DCS installations.

ABB AO2040

Application Areas

The ABB AO2040 is widely deployed in industries requiring precise analog control:

- Oil & Gas: Controls valve positions in pipelines, regulates pump speeds in refineries, and manages pressure control systems in offshore platforms to ensure safe and efficient operations.

- Chemical Processing: Adjusts flow rates of reactants in batch processes, controls temperature in reactors, and manages distillation column parameters to optimize yield and product quality.

- Power Generation: Manages steam turbine governors, adjusts excitation systems in generators, and controls boiler feedwater valves to maintain stable power output and grid compliance.

- Water/Wastewater Treatment: Regulates chemical dosing pumps, adjusts blower speeds in aeration tanks, and controls flow meters to ensure efficient water treatment and distribution.

Specific applications include:

- Closed-Loop Control: Integrates with PID controllers to maintain process variables (e.g., temperature, pressure) at setpoints, ensuring consistent output in manufacturing lines.

- Machine Automation: Controls robotic arm movements, adjusts conveyor belt speeds, and manages spindle drives in CNC machines for precise positioning and speed regulation.

- Energy Management: Optimizes HVAC systems in industrial facilities by controlling damper positions and chiller outputs, reducing energy consumption and operational costs.

By delivering reliable analog control and diagnostic capabilities, the AO2040 enhances process efficiency, reduces waste, and minimizes the risk of operational disruptions.

Related Products

- AO2020: A 2-channel variant of the AO2040, suitable for smaller-scale applications requiring fewer output channels.

- AI523: Analog Input Module with 8 channels, pairing with the AO2040 to create complete analog control loops in automation systems.

- DI810: Digital Input Module for integrating discrete signals (e.g., switch statuses) with the AO2040’s analog control functions.

- DO810: Digital Output Module for triggering alarms or actuators in response to analog control signals from the AO2040.

- AC 800M Controller: The primary controller for the AO2040, providing advanced logic processing and communication capabilities within the 800xA system.

- TB840A: Termination Unit for the S800 I/O system, simplifying field wiring connections for the AO2040 and reducing installation time.

- PM866AK01: Processor Module with integrated Ethernet and Profibus interfaces, enhancing the AO2040’s connectivity in complex networks.

- CI854K01: Communication Interface Module for connecting the AO2040 to Profibus DP or Ethernet/IP networks, enabling integration with third-party systems.

ABB AO2040

Installation and Maintenance

Installation Preparation:

Before installing the ABB AO2040, ensure the DIN rail is securely mounted and the S800 I/O rack is powered off. Connect the module to the rack using the S800 I/O bus connector, then secure it with DIN rail clips. For field wiring, use shielded cables to connect the analog outputs to field devices, ensuring proper grounding to minimize interference. Power up the system and configure the module using ABB’s Control Builder M, assigning channel parameters and fail-safe values as required.

Before installing the ABB AO2040, ensure the DIN rail is securely mounted and the S800 I/O rack is powered off. Connect the module to the rack using the S800 I/O bus connector, then secure it with DIN rail clips. For field wiring, use shielded cables to connect the analog outputs to field devices, ensuring proper grounding to minimize interference. Power up the system and configure the module using ABB’s Control Builder M, assigning channel parameters and fail-safe values as required.

Maintenance Recommendations:

- Routine Checks: Inspect the module monthly for loose connections, corrosion, or overheating. Use the module’s diagnostic tools to verify output accuracy against a calibrated multimeter.

- Calibration: Perform annual calibration of each channel to ensure compliance with accuracy standards. Document calibration results and replace faulty channels promptly.

- Firmware Updates: Regularly update the module’s firmware via the AC 800M controller to access new features and security patches, following ABB’s recommended procedures.

- Spare Parts Management: Store spare AO2040 modules in anti-static packaging at ambient temperature (15–35°C) with low humidity to preserve component performance. Test spares periodically to ensure functionality.

Product Warranty

Our company provides a 12-month quality warranty for the ABB AO2040, covering hardware defects under normal use. In the event of performance issues, we offer prompt replacement services to minimize operational downtime. For discontinued or hard-to-find models, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick fulfillment of urgent orders. Our technical support team is available 24/7 to assist with installation, configuration, and troubleshooting, delivering reliable solutions to keep your automation systems operating at peak efficiency.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

ABB RXIDK 2H 1MRK000838-HA Safety system

ABB REF543KB127AAAA Distributed control

ABB PFEA111-20 3BSE028140R0020 Terminal panel

ABB PFEA111-20 3BSE050090R20 PDP panel

ABB PM511V16 3BSE011181R1 programmable

ABB S-093H 3BHB009885R0004 Logic controller

ABB PPC905AE101 3BHE014070R0101 Communication input interface component

ABB SA811F Communication output interface component

ABB REM610 Module connector

ABB CS513 3BSE000435R1 Double output

ABB REF543KB127AAAA Distributed control

ABB PFEA111-20 3BSE028140R0020 Terminal panel

ABB PFEA111-20 3BSE050090R20 PDP panel

ABB PM511V16 3BSE011181R1 programmable

ABB S-093H 3BHB009885R0004 Logic controller

ABB PPC905AE101 3BHE014070R0101 Communication input interface component

ABB SA811F Communication output interface component

ABB REM610 Module connector

ABB CS513 3BSE000435R1 Double output

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: