Description

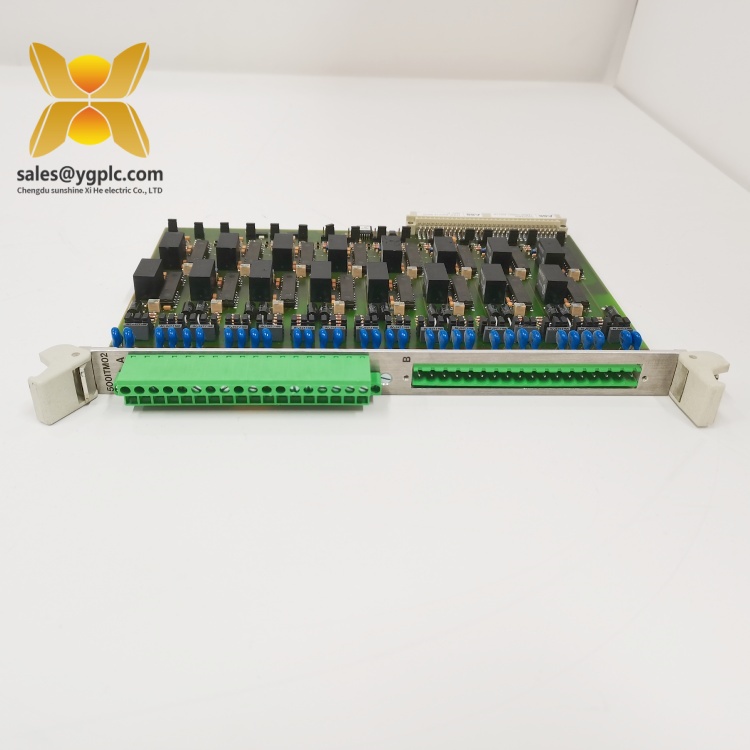

Product Overview — ABB 500ITM02

As a leading brand in industrial automation, ABB delivers innovative solutions that enhance efficiency, reliability, and safety for global manufacturing and process industries. The ABB 500ITM02 is a high-performance industrial I/O (Input/Output) module designed to bridge the gap between field devices and control systems, enabling seamless data transmission and precise process control. Engineered for harsh industrial environments, the ABB 500ITM02 integrates advanced hardware and software features to meet the demands of modern automation workflows, making it an ideal choice for applications requiring stable, real-time data acquisition and device coordination.

Whether used in standalone systems or integrated into larger distributed control architectures, the ABB 500ITM02 ensures consistent performance, reducing downtime and optimizing operational efficiency. Its compact design and flexible configuration options allow easy integration into existing cabinets, while its compatibility with industry-standard protocols ensures interoperability with a wide range of ABB and third-party control devices.

Technical Specifications — ABB 500ITM02

| Parameter | Details |

|---|---|

| Input Voltage | 24V DC (±10% tolerance) |

| Power Consumption | Typical: ≤ 5W; Max: 7W (at full I/O load) |

| I/O Channels | 8 Digital Inputs (DI); 4 Digital Outputs (DO); 2 Analog Inputs (AI) |

| Communication Protocols | Modbus RTU, PROFIBUS DP, Ethernet/IP |

| Operating Temperature | -20°C to +70°C (-4°F to +158°F) |

| Protection Rating | IP20 (panel-mounted); IP40 (with optional protective cover) |

| Dimensions (W×H×D) | 120mm × 105mm × 75mm (4.72in × 4.13in × 2.95in) |

| Weight | Approx. 0.32kg (0.71lbs) (without terminals) |

| Certifications | CE, UL, CSA, ATEX (for hazardous areas) |

ABB 500ITM02

Related Products — ABB 500ITM02

To complement the ABB 500ITM02 and create a complete automation solution, ABB offers a range of compatible products tailored to industrial needs. These include:

- ABB 500BIO01: A compact coupling module for multi-system communication, ideal for extending the ABB 500ITM02’s connectivity to remote devices.

- ABB 500COM01: An Ethernet communication module that enhances the ABB 500ITM02’s protocol support with OPC UA, enabling cloud-based data integration.

- ABB 500AI03: A high-precision analog input module, designed to work with the ABB 500ITM02 for applications requiring accurate measurement of pressure, temperature, and flow.

- ABB ACS480: A variable frequency drive (VFD) that integrates seamlessly with the ABB 500ITM02 to control motor speed and energy usage in manufacturing lines.

Main Features and Advantages — ABB 500ITM02

The ABB 500ITM02 stands out in industrial automation due to its robust design and user-centric features, delivering tangible benefits to operators and system integrators:

1. Multi-Protocol Compatibility

Support for Modbus RTU, PROFIBUS DP, and Ethernet/IP ensures the ABB 500ITM02 works seamlessly with existing control systems—whether ABB DCS, third-party PLCs, or legacy devices. This eliminates the need for costly protocol converters, simplifying system integration.

2. Rugged Industrial Design

With an operating temperature range of -20°C to +70°C and ATEX certification for hazardous areas, the ABB 500ITM02 performs reliably in harsh conditions, such as chemical plants, oil refineries, and outdoor energy facilities. Its IP20 rating (with optional IP40 cover) protects against dust and accidental contact.

3. Flexible I/O Configuration

The ABB 500ITM02’s 8 DI, 4 DO, and 2 AI channels can be customized to match specific application needs. Digital inputs accept dry contact or voltage signals, while analog inputs support 4-20mA or 0-10V signals—making it suitable for monitoring sensors, actuators, and process variables.

4. Real-Time Data Transmission

Equipped with high-speed communication ports, the ABB 500ITM02 transmits data with minimal latency, ensuring control systems receive accurate, up-to-date information for fast decision-making. This is critical for time-sensitive processes, such as assembly line synchronization or emergency shutdown systems.

5. Easy Installation and Configuration

The ABB 500ITM02 uses detachable spring terminals for quick wiring, reducing installation time. Its intuitive configuration software (compatible with ABB’s Control Builder Plus) allows users to set up I/O parameters, protocol settings, and alarm thresholds without specialized programming skills.

ABB 500ITM02

Installation and Maintenance — ABB 500ITM02

Proper installation and regular maintenance ensure the ABB 500ITM02 delivers long-term reliability. Follow these guidelines for optimal performance:

Installation Requirements

- Mount the ABB 500ITM02 vertically in a control cabinet with adequate ventilation (minimum 50mm clearance on all sides) to prevent overheating.

- Use 24V DC power supplies with stable output to avoid voltage fluctuations that may affect performance.

- For communication cables, use shielded twisted-pair wires (STP) to reduce electromagnetic interference (EMI). Maximum cable length: 1000m for Ethernet, 1200m for PROFIBUS DP.

- Ensure all wiring complies with local electrical codes (e.g., NEC, IEC) and ABB’s installation manual for the ABB 500ITM02.

Maintenance Tips

- Inspect the ABB 500ITM02 monthly for dust buildup; clean with a dry, lint-free cloth (do not use liquids).

- Check terminal connections quarterly to ensure they are tight and free from corrosion.

- Update the module’s firmware annually using ABB’s official software to access new features and security patches.

- In case of errors, refer to the ABB 500ITM02’s diagnostic LED indicators (power, communication, I/O status) to quickly identify issues (e.g., red LED for power failure, flashing yellow for communication errors).

Application Fields — ABB 500ITM02

The ABB 500ITM02 is versatile enough to serve multiple industrial sectors, addressing unique challenges in each:

1. Manufacturing

In automotive, electronics, and consumer goods manufacturing, the ABB 500ITM02 monitors conveyor belts, robotic arms, and quality control sensors. Its real-time data transmission ensures production lines run smoothly, while its flexible I/O supports quick reconfiguration for product changes.

2. Energy and Utilities

For power plants (solar, wind, thermal) and water treatment facilities, the ABB 500ITM02 tracks voltage, current, and flow rates. Its ATEX certification makes it safe for use in oil and gas pipelines, where it controls valves and monitors pressure to prevent leaks.

3. Chemical and Pharmaceutical

In chemical processing and pharmaceutical manufacturing, the ABB 500ITM02 maintains precise control over temperature, pH levels, and chemical dosing. Its rugged design withstands corrosive environments, while its reliable data acquisition ensures compliance with regulatory standards (e.g., FDA, EMA).

4. Food and Beverage

For food processing plants, the ABB 500ITM02 monitors refrigeration systems, packaging machines, and hygiene sensors. Its IP40 optional cover protects against moisture and cleaning agents, ensuring compliance with food safety regulations (e.g., HACCP).

ABB 500ITM02

Product Guarantee — ABB 500ITM02

ABB stands behind the quality of the ABB 500ITM02 with a comprehensive warranty and support program:

- Warranty Period: 12 months from the date of delivery, covering defects in materials and workmanship. Extended warranties (2–5 years) are available for additional protection.

- Genuine Parts: All repairs and replacements for the ABB 500ITM02 use ABB genuine parts to ensure compatibility and performance.

- Technical Support: ABB’s global technical team provides 24/7 assistance for troubleshooting, configuration, and integration. Users can access support via phone, email, or the ABB Customer Portal.

- Calibration Services: Optional annual calibration for the ABB 500ITM02’s analog inputs ensures measurement accuracy, critical for regulated industries.

To validate the warranty, keep a copy of the purchase invoice and register the ABB 500ITM02 on the ABB website within 30 days of installation.

Contact Us

For inquiries about the ABB 500ITM02, including pricing, availability, and technical support, please reach out via the following channels:

- WhatsApp: [WhatsApp +86 18859254943]

- Email: sales@ygplc.com

- Website: https://www.ygplc.com/

Our team will respond to your query within 24 hours, providing personalized solutions to meet your industrial automation needs.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: