Description

Product Overview

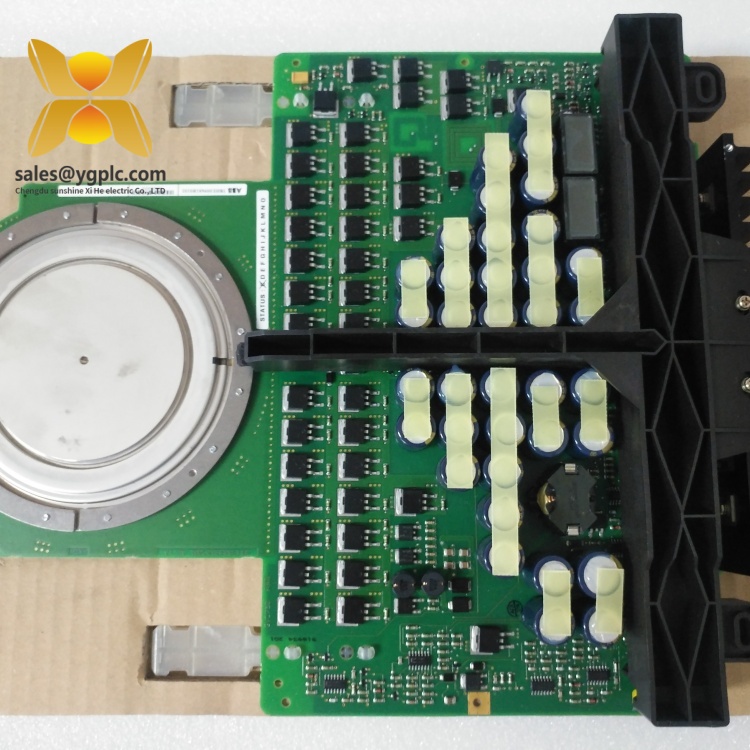

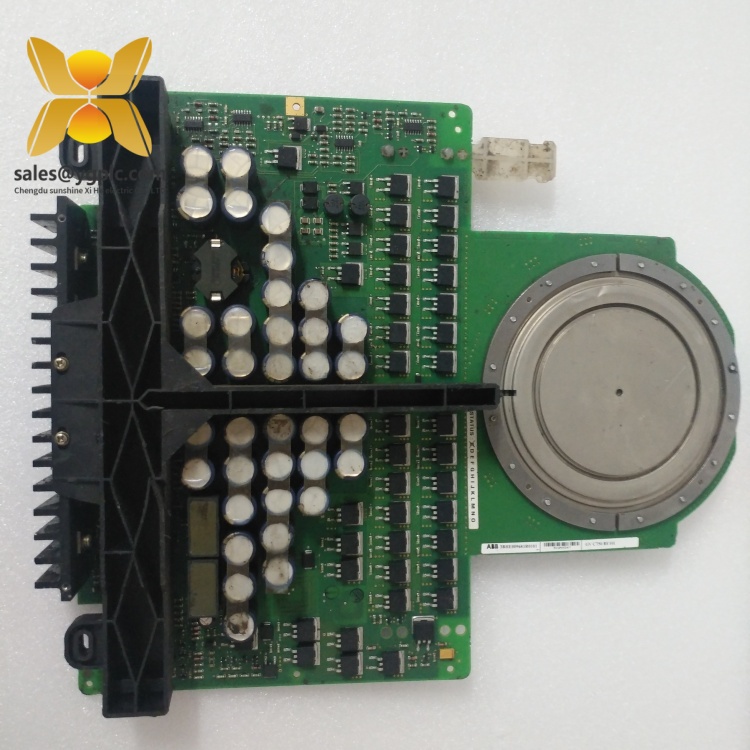

The ABB 5SHY4045L0001 / 3BHB018162R0001 IGCT Module is a high-performance Integrated Gate-Commutated Thyristor (IGCT) designed for demanding medium and high-voltage power conversion applications. Built with robust engineering and precision manufacturing, this module combines the high current-carrying capacity of traditional Gate Turn-Off (GTO) thyristors with the fast switching performance of modern Insulated Gate Bipolar Transistors (IGBTs). The result is a power device capable of delivering exceptional efficiency, reliability, and thermal stability in industrial-grade environments.

IGCT technology eliminates the need for complex snubber circuits, simplifying overall system architecture and reducing both design complexity and cost. Its optimized conduction and switching characteristics enable high power density solutions suitable for high-frequency switching without sacrificing operational stability.

This specific model, 5SHY4045L0001, paired with the 3BHB018162R0001 driver board, is widely deployed in medium-voltage drives, static VAR compensators, HVDC transmission systems, and large industrial motor control systems. With a compact form factor and rugged construction, it is engineered for long service life even under high load conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | ABB (Original Design) |

| Model Number | 5SHY4045L0001 / 3BHB018162R0001 |

| Device Type | IGCT (Integrated Gate-Commutated Thyristor) |

| Rated Voltage | 4.5 kV |

| Rated Current | 4000 A (typical) |

| Switching Frequency | Up to several kHz depending on application |

| Gate Unit Compatibility | Compatible with ABB standard IGCT gate drives |

| Thermal Resistance (Junction-Case) | < 0.015 K/W |

| Storage Temperature Range | –40 °C to +125 °C |

| Mounting Type | Panel/Chassis Mount |

| Dimensions (Approx.) | 160 mm × 160 mm × 120 mm |

| Weight (Approx.) | 0.8 kg |

| Country of Origin | United States |

| Warranty | Provided by Xiamen Xiongba E-commerce Co., Ltd., not by ABB |

5SHY4045L0001 3BHB018162R0001

Key Features and Benefits

-

High Power Handling Capability

Designed to handle extremely high currents and voltages, enabling reliable performance in heavy industrial applications. -

Fast Switching Performance

IGCT architecture supports rapid turn-on and turn-off, minimizing switching losses and improving system efficiency. -

Reduced Circuit Complexity

No need for large and costly snubber circuits, saving space and reducing BOM (Bill of Materials) costs. -

Thermal Efficiency

Low thermal resistance ensures efficient heat dissipation, supporting high load operation without overheating. -

Mechanical Robustness

Built with industrial-grade materials to withstand vibration, shock, and harsh operating conditions. -

Long Service Life

Suitable for extended operational cycles, reducing downtime and maintenance costs. -

Compact Form Factor

Space-efficient design allows for easy integration into existing systems.

Applications

-

Medium Voltage Drives (MVDs) – Efficiently control large motors in industries such as mining, oil & gas, cement, and steel manufacturing.

-

HVDC Transmission Systems – High-voltage power transfer over long distances with minimal losses.

-

Static VAR Compensators (SVCs) – Improve power quality and grid stability in large electrical networks.

-

Marine Propulsion Systems – Provide reliable and efficient power control for electric ship propulsion.

-

Industrial Power Converters – High-frequency switching for industrial-scale energy conversion systems.

-

Wind and Hydro Power Plants – Support renewable energy applications requiring high reliability.

5SHY4045L0001 3BHB018162R0001

Installation Guidelines

-

Pre-Installation Checks

-

Ensure the module matches the system’s voltage and current requirements.

-

Verify compatibility with the gate driver unit.

-

-

Mounting

-

Use appropriate torque values when fastening to the heatsink.

-

Maintain even pressure distribution to prevent mechanical stress.

-

-

Cooling Requirements

-

Employ forced air or liquid cooling as per system design.

-

Maintain unobstructed airflow for optimal heat dissipation.

-

-

Electrical Connections

-

Ensure all high-voltage terminals are securely tightened.

-

Use insulated tools to prevent accidental short circuits.

-

-

Testing and Commissioning

-

Perform insulation resistance testing before energizing.

-

Gradually ramp up load during initial startup.

-

Maintenance Guidelines

-

Regular Visual Inspection – Check for signs of overheating, discoloration, or mechanical damage.

-

Thermal Monitoring – Ensure operational temperatures remain within specified limits.

-

Connection Integrity – Periodically re-tighten connections to maintain electrical contact quality.

-

Cleaning – Keep the module free from dust and contaminants using dry, non-conductive cleaning methods.

5SHY4045L0001 3BHB018162R0001

Warranty Statement

This product is covered by a warranty provided exclusively by Xiamen Xiongba E-commerce Co., Ltd., ensuring replacement or repair in the event of manufacturing defects or failures during the warranty period. This warranty is not provided by ABB and does not imply ABB’s brand guarantee. Customers can rely on our technical expertise, comprehensive after-sales support, and inventory availability for uninterrupted operation of their industrial systems.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: