Description

TRICONEX 3806E/9863-710 High-Current Analog Output Module

Product Overview

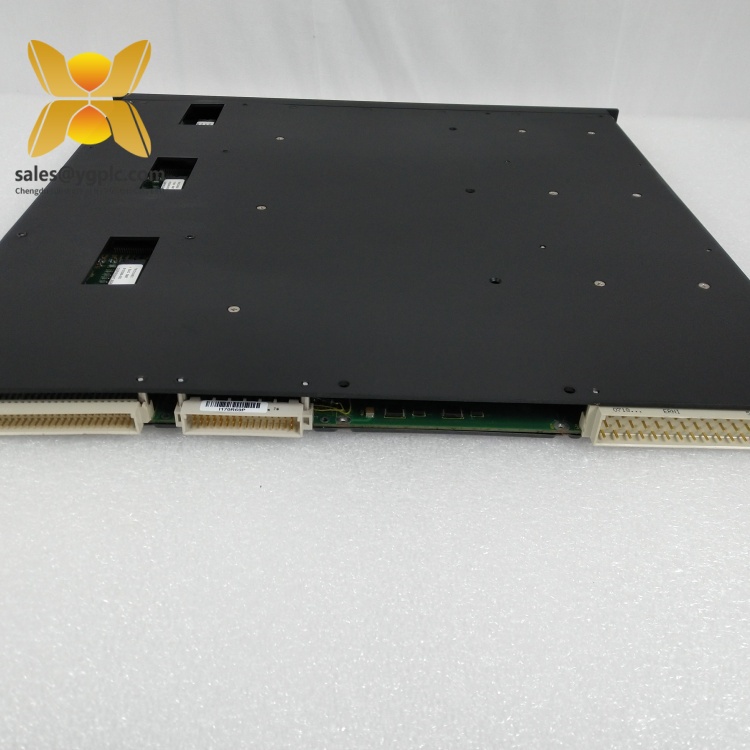

The TRICONEX 3806E/9863-710 is a high-reliability analog output module engineered for safety-critical industrial automation systems, specifically designed to integrate with Triple Modular Redundancy (TMR) architectures. As a core component of the TRICONEX Tricon safety system, this module serves as the interface between the central control logic and high-power field actuators—such as servo valves, motor drives, and proportional solenoids—delivering precise analog signals to ensure process control in high-risk environments. Certified to SIL 3 under IEC 61508 and IEC 61511 standards, the TRICONEX 3806E/9863-710 meets the strictest safety requirements, making it indispensable for applications like turbine compressor control, emergency shutdown systems (ESD), and high-integrity pressure protection systems (HIPPS) in oil and gas, chemical processing, and power generation industries.

Equipped to handle 4–20 mA and 20–320 mA output signals, the TRICONEX 3806E/9863-710 features 8 isolated output channels, each capable of driving high-current loads with high precision and stability. Its compact design (163 mm × 38 mm × 58 mm) and robust build (3 kg) allow seamless integration into existing Tricon racks, supporting both new installations and system upgrades. The module’s advanced diagnostic capabilities, combined with a -40°C to +70°C operating temperature range, ensure consistent performance in harsh industrial conditions, minimizing the risk of signal degradation or system failure. By providing real-time, redundant analog control, the TRICONEX 3806E/9863-710 forms the backbone of safe and efficient process automation, enabling precise regulation of critical plant operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Manufacturer | TRICONEX |

| Product Type | High-Current Analog Output Module |

| Output Signal | 4–20 mA (±6% over-range) and 20–320 mA (±6% over-range) |

| Number of Channels | 8 isolated channels |

| Physical Dimensions | 163 mm (height) × 38 mm (width) × 58 mm (depth) |

| Weight | 3 kg |

| Isolation Rating | 1500VAC galvanic isolation between channels and backplane |

| Operating Temperature | -40°C to +70°C |

| Safety Integrity Level | SIL 3 (IEC 61508/IEC 61511) |

| Output Accuracy | <0.25% of full-scale range (FSR) within 0–60°C |

| Over-Voltage Protection | 42.5VDC continuous |

| Response Time | <10 ms for signal updates |

| Resolution | 12 bits |

3806E/9863-710

Related Products

- TRICONEX 3805E: A 4–20 mA analog output module with enhanced diagnostics for general-purpose industrial applications.

- TRICONEX 3807: A bipolar analog output module designed for servo-control applications requiring ±60 mA signals.

- TRICONEX 3625: A digital output module for discrete actuator control in safety interlock applications.

- TRICONEX 4351B: A communication module enabling data transfer between Tricon systems and SCADA platforms.

- TRICONEX 8310: A power supply module designed to provide stable 24VDC power to Tricon I/O modules.

- TRICONEX 3721/N/C: A digital input module for sensor monitoring in hybrid analog-digital control systems.

- TRICONEX 3805H: A variant of the 3805E optimized for inductive loads, ensuring compatibility with high-inertia actuators.

Main Features and Advantages

The TRICONEX 3806E/9863-710 is defined by its TMR architecture, which duplicates critical components across three independent channels. This redundancy ensures that any single-channel fault is automatically detected and compensated for, eliminating single points of failure and maintaining system availability. Its SIL 3 certification validates its ability to reduce risk in high-hazard processes, providing compliance with global safety regulations.

A key advantage of the TRICONEX 3806E/9863-710 is its high-current capability, specifically designed to drive servo valves and other high-power actuators in turbomachinery applications. Its 20–320 mA output range allows precise control of hydraulic systems, ensuring smooth and responsive adjustments in turbine compressor speed, inlet guide vane positioning, and emergency shutdown sequences. The module’s self-calibration feature maintains accuracy over time, reducing the need for manual adjustments and minimizing downtime.

Environmental resilience is another standout feature. The TRICONEX 3806E/9863-710 operates reliably in extreme temperatures, high humidity (up to 95% non-condensing), and high-vibration environments, making it suitable for offshore platforms, refineries, and chemical plants. Its rugged design and long-term stability reduce maintenance requirements, lowering lifecycle costs for end-users.

3806E/9863-710

Installation and Maintenance

Pre-installation Preparations:

Before installing the TRICONEX 3806E/9863-710, verify that the Tricon rack is powered off and properly grounded to prevent electrical damage. Inspect the module for physical defects, such as bent pins or damaged connectors. Confirm compatibility with the Tricon system’s firmware version and ensure the backplane connectors are clean and free of corrosion. Use the module’s guide rails to align it with the rack slots, applying gentle pressure to seat the connectors fully—avoid excessive force to prevent backplane damage. Connect redundant 24VDC power supplies to the module’s dedicated terminals and wire the analog outputs to field devices using shielded cables to minimize electromagnetic interference.

Before installing the TRICONEX 3806E/9863-710, verify that the Tricon rack is powered off and properly grounded to prevent electrical damage. Inspect the module for physical defects, such as bent pins or damaged connectors. Confirm compatibility with the Tricon system’s firmware version and ensure the backplane connectors are clean and free of corrosion. Use the module’s guide rails to align it with the rack slots, applying gentle pressure to seat the connectors fully—avoid excessive force to prevent backplane damage. Connect redundant 24VDC power supplies to the module’s dedicated terminals and wire the analog outputs to field devices using shielded cables to minimize electromagnetic interference.

Maintenance Suggestions:

Regularly review system diagnostics via the Tricon configuration software to monitor TRICONEX 3806E/9863-710 channel status and detect anomalies early. Perform firmware updates as released by TRICONEX to address security enhancements and performance improvements. Clean the module’s exterior quarterly with a dry, lint-free cloth to remove dust, which can impede heat dissipation. For long-term storage, keep the module in an anti-static bag in a dry environment with temperatures between 0°C and 50°C. If a fault is detected, replace the module with a certified spare to maintain TMR integrity.

Regularly review system diagnostics via the Tricon configuration software to monitor TRICONEX 3806E/9863-710 channel status and detect anomalies early. Perform firmware updates as released by TRICONEX to address security enhancements and performance improvements. Clean the module’s exterior quarterly with a dry, lint-free cloth to remove dust, which can impede heat dissipation. For long-term storage, keep the module in an anti-static bag in a dry environment with temperatures between 0°C and 50°C. If a fault is detected, replace the module with a certified spare to maintain TMR integrity.

Application Fields

The TRICONEX 3806E/9863-710 is widely deployed in safety instrumented systems (SIS) and critical control applications across high-risk industries. In oil and gas refineries, it regulates turbine compressor inlet guide vanes, pressure control valves, and flare gas systems, ensuring precise adjustment of process parameters to prevent overpressure or equipment failure. For example, in a large ammonia plant in Egypt, the module was used to control compressor speed and emergency shutdown sequences, ensuring safe operation of the plant’s high-pressure synthesis loops .

Chemical plants rely on the TRICONEX 3806E/9863-710 to drive reactor feed pumps, pH control valves, and distillation column actuators, enabling tight control of reaction rates and product quality. Power generation facilities use it to manage turbine governor systems, boiler drum level control, and generator excitation systems, supporting stable power output and safe load shedding during grid disturbances. It also finds use in pharmaceutical manufacturing, where it adjusts sterilization chamber pressure and temperature via proportional valves, maintaining compliance with cGMP standards. By providing accurate, redundant analog control, the TRICONEX 3806E/9863-710 ensures industrial systems operate efficiently while adhering to the highest safety and regulatory benchmarks.

3806E/9863-710

Product Guarantee

Our company offers a one-year quality warranty for the TRICONEX 3806E/9863-710, covering hardware malfunctions not caused by improper installation, misuse, or environmental damage. During the warranty period, any malfunctioning module will be replaced promptly to minimize operational disruption. As a 17-year-old industrial control distribution leader, we maintain extensive stock of TRICONEX 3806E/9863-710 units and related spares, ensuring rapid fulfillment of urgent orders. Our global supply chain network enables us to source even discontinued or hard-to-find models, supporting the longevity of legacy systems. We also offer technical support to assist with installation, configuration, and troubleshooting, ensuring customers maximize the module’s performance. For inquiries or quotations, contact us via WhatsApp: +86 18859254943 or email: sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: