Description

Product Overview

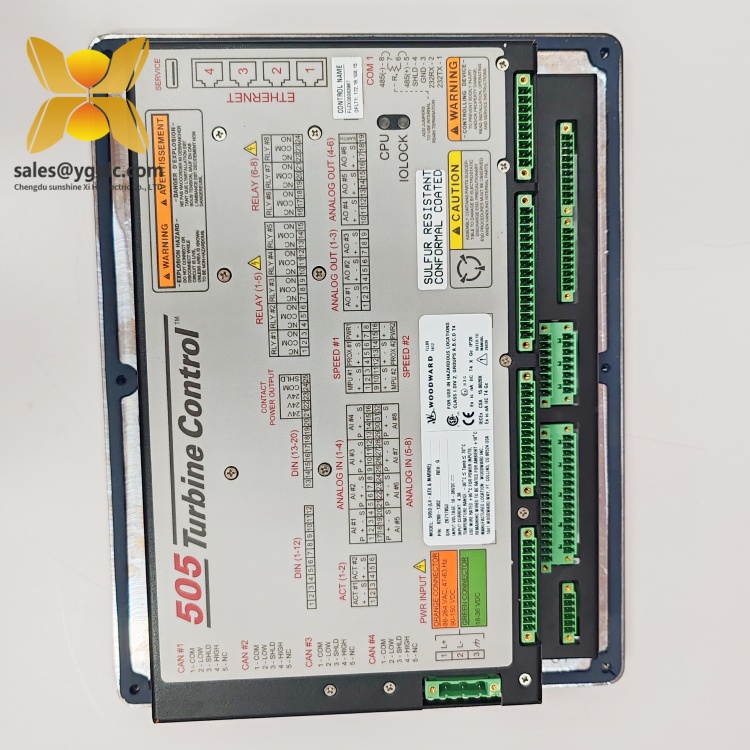

The WOODWARD 8200-1302 is a digital governor turbine control, an integral part of the Woodward 505 digital governor series. This device plays a pivotal role in regulating the speed of steam turbines, ensuring stable and efficient operation. It serves as a critical component within industrial automation systems, particularly in power generation and industrial processes that rely on steam turbines.

WOODWARD 8200-1302 features an operator control panel which functions as a graphical interface and keyboard. This allows operators to make precise adjustments to the turbine and facilitates seamless communication with the turbine system. Configuration of the device can be easily carried out via the Modbus communication port located on it. With a wide range of available functions, it offers great flexibility. For instance, it has automatic start sequences for both hot start and cold start, with temperature input options enhancing its adaptability. It can handle critical speed circumvention across three speed bands, and comes equipped with ten external alarm inputs and ten external DI (Digital Input) trip inputs. The unit also provides a trip indication with associated RTC (Real-Time Clock) time stamps for enhanced monitoring and troubleshooting.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 8200-1302 |

| Manufacturer | WOODWARD |

| Product Type | Digital Governor Turbine Control |

| Voltage Input | N/A (not specified in available data, typically operates within standard industrial voltage ranges) |

| Communication Protocol | Modbus (for configuration), Ethernet (for connection to factory DCS, service tools, and RemoteView operator control panel), CANOpen (for connection to Woodward variable stroke actuators and DSLC-II power management network) |

| Number of Redundant Speed Inputs | 2 (accepts magnetic pickup device, eddy current probe, or proximity probe) |

| Number of Analog Inputs | 8 (configurable for any of twenty-seven functions) |

| Number of Contact Inputs | 20 (first four default for stop raising speed setpoints, resetting, and lowering speed setpoints) |

| Control Output | 2 x 4 – 20 mA |

| Relay Contact Output | 8 x Form-C |

| Front Panel Features | Emergency trip key, backspace/delete keys, shift keys, view, mode, ESC, and home keys; navigation cross keys, soft key commands, four LEDs for control and hardware state indication |

| Display Type | 8.4-inch liquid crystal display |

| Operating Temperature Range | -22°F to 158°F (-30°C to 70°C) |

| Storage Temperature Range | -22°F to 158°F (-30°C to 70°C) |

| EMC Compliance | Complies with EMC immunity EN 61000 – 6 – 2 standard |

| Housing Type | IACS UR E10 type (commercial marine), with ATEX, IP – 54, and pollution degree 3 protection |

8200-1302

Main Features and Advantages

The WOODWARD 8200-1302 offers a host of features that set it apart. Its advanced integrated multi – language HMI screen simplifies configuration and operation for users worldwide. This multi – language support, including languages like Chinese, enhances usability and accessibility.

Built upon the reliable 505 platform, which has a global reputation for dependability, the 8200 – 1302 inherits a long – standing legacy of stable performance. The device’s ability to handle a variety of input types, such as analog inputs (4 – 20 mA channels with loop power) and multiple contact inputs, allows for seamless integration with different sensors and control systems in a plant.

It comes with intelligent and adaptive control algorithms. For example, the OptiTune adaptive PID technology ensures optimal turbine performance settings. The acceleration PID function limits overshoot, enabling stable and efficient factory start – ups. Additionally, it has features like three critical speed avoidance bands, reverse rotation induction and alarm, and high – speed data logging for monitoring turbine operation and stress. This includes recording information such as running time and first – trip data, which is invaluable for predictive maintenance and overall system health assessment.

Application Fields

The WOODWARD 8200-1302 finds extensive applications in power generation plants where steam turbines are used to generate electricity. It precisely controls the speed of the turbines, ensuring a stable power output. In industrial settings, such as in manufacturing plants that use steam – powered machinery, this digital governor turbine control helps maintain the proper operation of the steam turbines driving the production processes.

8200-1302

It is also well – suited for the energy sector, including oil and gas facilities where steam turbines are utilized for various purposes like compression and pumping. In the marine industry, ships equipped with steam – turbine – based propulsion systems can benefit from the 8200 – 1302’s accurate speed control capabilities. This helps in maintaining the desired speed and performance of the ship’s engines under different operating conditions. Overall, any application that requires precise and reliable speed control of steam turbines can leverage the capabilities of the WOODWARD 8200 – 1302.

Related Products

- WOODWARD 8200-1502: Part of the same 8200 series, likely has similar functionality but may differ in certain features such as the number of inputs/outputs or specific control algorithms, suitable for applications with slightly different requirements.

- WOODWARD 8200-1300: Another model in the series, may have variations in its communication capabilities or the level of integration with other systems, providing options for different industrial setups.

- WOODWARD 8200-507: Could offer different performance characteristics, perhaps optimized for specific types of turbines or operating conditions, allowing users to choose the most suitable model for their needs.

- WOODWARD 9907-164: It can be a direct upgrade option for existing 505 traditional turbine governor control devices, sharing some similarities with the 8200 – 1302 but with enhanced features for modernizing older systems.

- WOODWARD 5404-1801: This is a wiring kit, specifically designed to be used in the upgrade process from the old 505 to the new 505D, facilitating the installation and connection of devices like the 8200 – 1302.

Installation and Maintenance

Installation Preparations: Before installing the WOODWARD 8200-1302, ensure that the area is free from excessive dust, moisture, and strong electromagnetic interference. Check all the connection points and wiring diagrams provided in the product manual. Verify that the power supply to the installation site meets the device’s voltage and current requirements. Prepare the necessary tools such as screwdrivers, wire strippers, and multimeters for a smooth installation process.

8200-1302

Maintenance Suggestions: Regularly inspect the WOODWARD 8200-1302 for any signs of physical damage, such as cracks in the housing or loose connections. Check the display for any abnormal readings or error messages. Periodically clean the device to prevent dust accumulation, which could affect its performance. It is also advisable to perform software updates when available to ensure the device has the latest features and bug fixes. In case of any issues, refer to the detailed troubleshooting guide in the product manual.

Product Guarantee

Our company provides a one – year quality warranty service for the WOODWARD 8200-1302, covering hardware failures caused by non – human factors. During the warranty period, if the product experiences abnormal performance or functional failures, we will provide replacement services. Additionally, for discontinued models or urgent needs, we rely on our global supply chain network to quickly respond to customers’ procurement needs for scarce spare parts, enabling the continuous and stable operation of industrial systems.

CONVERTEAM P110-6052 Safety system

FOXBORO P0926GV FBM231 Distributed control

AMAT 0010-23716 Terminal panel

PACIFIC 33VM52-000-29 PDP panel

Nabtesco BTC-304 programmable

DEIF PSM-1 Logic control module

DEIF SCM-1 Switch input terminal board

GE IC752SPL013-BA I/O fault diagnosis

ABB 500SCM01 1MRB150004R0001 1MRB200059-C Logic controller

ABB 500TRM02 1MRB150011R0001 Control panel

Elmo G-TUB30-480ERSS0 Double output

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: