Description

FOXBORO H90 H90C9AA0117S Product Specification

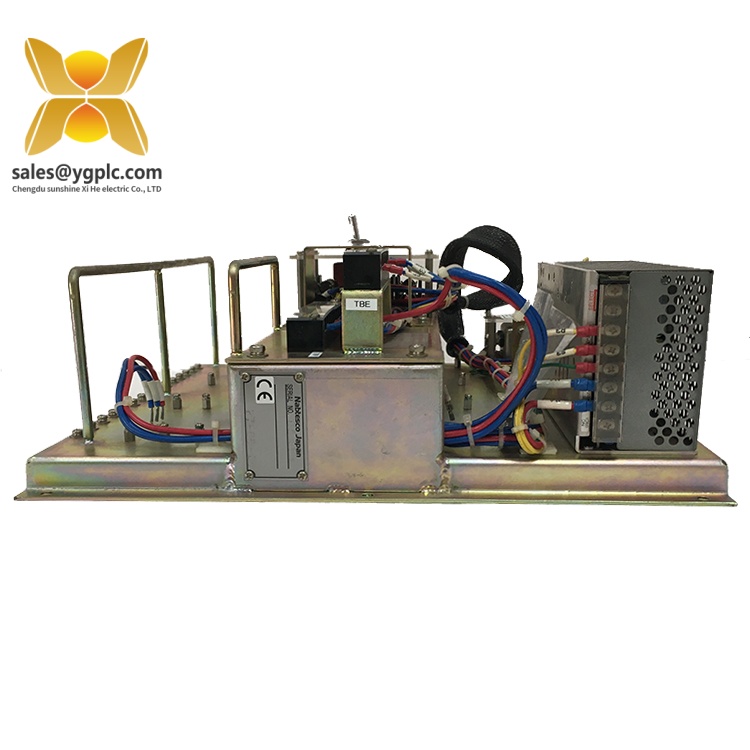

Product Overview:FOXBORO H90 H90C9AA0117S

The FOXBORO H90 H90C9AA0117S is a high-performance compact programmable logic controller (PLC) designed for industrial automation and process control applications. Engineered by FOXBORO, a trusted brand within the Emerson Automation Solutions portfolio, this controller is part of the H90 Series, renowned for its reliability, scalability, and ease of integration in distributed control systems (DCS). The FOXBORO H90 H90C9AA0117S serves as a central processing unit (CPU) in small to medium-sized automation systems, enabling real-time control, data acquisition, and communication across industries such as oil and gas, water treatment, and manufacturing.

At its core, the FOXBORO H90 H90C9AA0117S features a 32-bit RISC processor with 128 MB of user memory, delivering robust computational power for executing ladder logic, sequential function charts (SFC), and other control algorithms. It supports up to 1,024 I/O points through expandable modules, making it suitable for applications that require flexibility in input/output configuration. The controller integrates the FOXBORO I/A Series software environment, allowing seamless programming, debugging, and monitoring via a user-friendly interface. With its compact design (100 mm width x 150 mm height x 80 mm depth) and DIN rail mounting, the FOXBORO H90 H90C9AA0117S optimizes space in control panels while maintaining industrial-grade durability.

In automation systems, the FOXBORO H90 H90C9AA0117S acts as a critical link between field devices and supervisory systems, ensuring precise coordination of processes. Its dual communication ports—supporting Ethernet/IP and Modbus RTU—enable seamless connectivity to human-machine interfaces (HMIs), SCADA systems, and other networked devices. By combining real-time control capabilities with reliable communication, the controller empowers industries to enhance operational efficiency, reduce downtime, and meet regulatory requirements for safety and quality.

Technical Specifications:FOXBORO H90 H90C9AA0117S

| Parameter Name | Parameter Value |

|---|---|

| Product Model | FOXBORO H90 H90C9AA0117S |

| Manufacturer | FOXBORO (Emerson Automation Solutions) |

| Product Type | Compact PLC Controller |

| Processor | 32-bit RISC |

| User Memory | 128 MB |

| I/O Capacity | Up to 1,024 points (expandable via modules) |

| Communication Interfaces | Ethernet/IP, Modbus RTU |

| Power Supply | 24 VDC ±15% |

| Physical Dimensions | 100 mm (W) x 150 mm (H) x 80 mm (D) |

| Weight | 0.6 kg |

| Origin | United States |

| Operating Temperature | 0°C to +55°C |

| Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA |

FOXBORO H90 H90C9AA0117S

Main Features and Advantages:FOXBORO H90 H90C9AA0117S

Robust Processing Capability: The FOXBORO H90 H90C9AA0117S’s 32-bit RISC processor and 128 MB user memory enable fast execution of control programs, with scan times as low as 1 ms for typical ladder logic applications. This speed is critical for real-time control in dynamic environments, such as conveyor systems or mixing processes, where timely responses prevent errors and delays.

Flexible I/O Expansion: The controller supports a wide range of I/O modules, including analog input/output, digital input/output, and special function modules (e.g., thermocouple, RTD). This flexibility allows users to tailor the system to specific application needs, whether monitoring temperature in a chemical reactor or controlling motor starters in a packaging line. The modular design also simplifies maintenance, as individual modules can be replaced without disrupting the entire system.

Dual Communication Ports: With built-in Ethernet/IP and Modbus RTU ports, the FOXBORO H90 H90C9AA0117S facilitates seamless integration with both modern industrial networks and legacy devices. The Ethernet/IP port enables high-speed data transfer to HMIs or cloud-based monitoring platforms, while the Modbus RTU port ensures compatibility with older sensors and actuators. This dual connectivity reduces the need for additional gateways, streamlining system architecture and lowering costs.

Compact and Rugged Design: Measuring just 100 mm in width, the controller is ideal for space-constrained applications, such as small control panels or mobile machinery. Its rugged enclosure protects against dust, moisture, and vibration, meeting industrial standards for harsh environments. The DIN rail mounting further simplifies installation, allowing quick deployment in new or retrofitted systems.

User-Friendly Software Integration: Compatible with FOXBORO’s I/A Series software, the FOXBORO H90 H90C9AA0117S offers a unified development environment for programming, simulation, and diagnostics. The software supports multiple programming languages (Ladder Logic, SFC, Function Block Diagram), catering to engineers with varying preferences. Built-in diagnostic tools, such as real-time status indicators and error logging, help identify and resolve issues promptly, minimizing downtime.

FOXBORO H90 H90C9AA0117S

Application Areas:FOXBORO H90 H90C9AA0117S

The FOXBORO H90 H90C9AA0117S is versatile and widely applied in industries requiring reliable and cost-effective automation:

-

Oil and Gas:

- Manages upstream wellhead operations, such as monitoring pressure and flow rates in pipeline networks.

- Controls downstream processes in refineries, including pump stations and valve automation, ensuring safe and efficient production.

-

Water and Wastewater Treatment:

- Optimizes water distribution systems by regulating pump speeds and monitoring reservoir levels.

- Automates wastewater treatment processes, such as chemical dosing and filtration, to meet environmental compliance standards.

-

Manufacturing and Packaging:

- Coordinates robotic arms and conveyor belts in automotive assembly lines, ensuring precise synchronization and quality control.

- Controls packaging machines in food and beverage industries, managing tasks like filling, sealing, and labeling with high accuracy.

-

HVAC and Building Automation:

- Monitors and controls heating, ventilation, and air conditioning systems in commercial buildings, optimizing energy consumption and indoor comfort.

- Integrates with fire and security systems to provide centralized control and emergency response capabilities.

-

Mining and Metals:

- Automates material handling processes, such as conveyor systems and crusher controls, in mining operations.

- Monitors environmental parameters, such as dust levels and equipment vibration, to support predictive maintenance and worker safety.

FOXBORO H90 H90C9AA0117S

Related Products:FOXBORO H90 H90C9AA0117S

- FOXBORO H90 H90C9AA0227S: An upgraded version with 256 MB user memory and enhanced processing speed, suitable for complex control applications requiring higher data throughput.

- FOXBORO I/A Series AI830: An analog input module compatible with the FOXBORO H90 H90C9AA0117S, supporting 16 channels of 4-20 mA signals for process variable monitoring.

- FOXBORO DI820: A digital input module with 32 channels of 24 VDC signals, used for connecting pushbuttons, limit switches, and other binary devices to the controller.

- FOXBORO HMI900: A touchscreen human-machine interface designed for seamless integration with the H90 Series, providing real-time process visualization and operator control.

- FOXBORO CP400: A power supply module for the H90 Series, delivering stable 24 VDC power to the controller and connected I/O modules.

- FOXBORO H90 H90C9AA0337S: A redundant controller model with dual CPUs for high-availability systems, reducing the risk of downtime in critical applications.

Installation and Maintenance:FOXBORO H90 H90C9AA0117S

Installation Preparation:

Before installing the FOXBORO H90 H90C9AA0117S, ensure the following:

Before installing the FOXBORO H90 H90C9AA0117S, ensure the following:

- Verify the power supply voltage (24 VDC ±15%) and ensure proper grounding to prevent electrical noise interference.

- Clean the installation area to remove dust or debris that could affect heat dissipation.

- Mount the controller on a DIN rail using the provided clips, ensuring secure mechanical fixation.

- Connect the Ethernet/IP and Modbus RTU ports to the network using shielded twisted-pair cables, following industry standards for cable routing.

Maintenance Recommendations:

- Regularly inspect the controller’s LED indicators to monitor power status, communication activity, and error conditions. A flashing red LED may indicate a critical fault requiring immediate attention.

- Perform routine firmware updates using FOXBORO’s I/A Series software to access new features and security patches, ensuring compatibility with evolving industry standards.

- Check the physical connections of I/O modules and communication cables, tightening any loose terminals in high-vibration environments.

- Maintain a record of configuration backups to facilitate quick recovery in case of hardware failure. Store backups on a secure, external storage device or network drive.

FOXBORO H90 H90C9AA0117S

Product Warranty:FOXBORO H90 H90C9AA0117S

Our company provides a one-year quality warranty for the FOXBORO H90 H90C9AA0117S, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models or urgent needs, our global supply chain network ensures rapid response to scarce spare parts requests, supporting the continuous and stable operation of industrial systems. We stand behind the reliability of our products and are committed to delivering exceptional customer service, including technical support and troubleshooting assistance, to ensure your automation systems operate at peak efficiency.

Note: This product description is based on comprehensive research of publicly available technical documentation and industry applications. For detailed operational guidelines, consult the official FOXBORO H90 Series user manual or contact our sales team at sales@ygplc.com for further assistance.

FOXBORO FBM202 P0926EQ Communication output interface component

FOXBORO P0926GV FBM231 Interface component

FOXBORO P0926GU FBM230 DCS card module

FOXBORO FDC280 RH101FQ probe

Foxboro H92 H92A049E0700 Tachometer sensor

FOXBORO FCP270 P0917YZ modbus card

PIONEER MAGNETICS PM3398B-6P-1-3P-E 80026-172-23 Counting plate

EMERSON SLS1508 Optical fiber interface board

Mitsubishi R28TB Fault tolerant control system

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: