Description

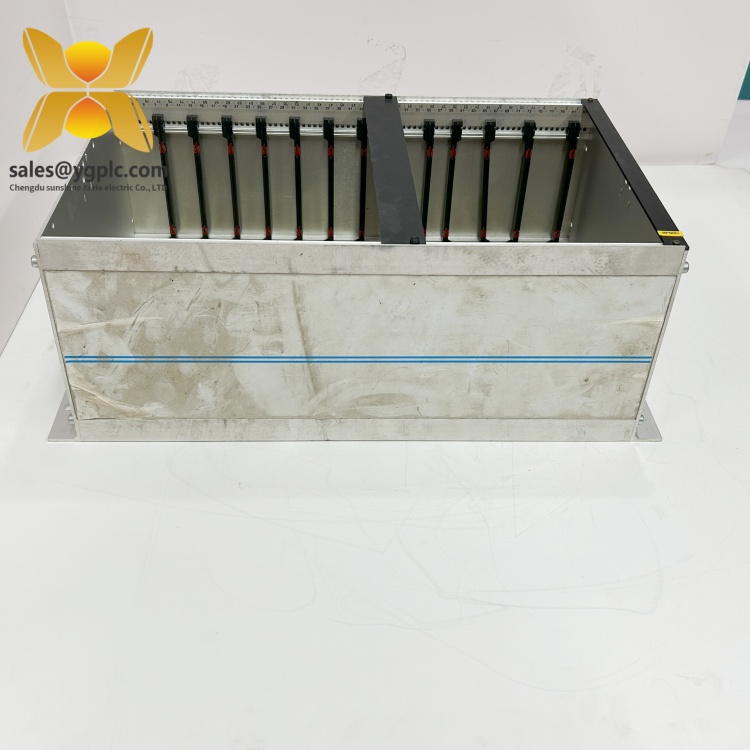

Product Overview

The DEIF DELOMATIC – 3 DGU2 is a high – performance and highly flexible multi – function control system, designed specifically for the control and protection of generator plants. As an integral part of DEIF’s renowned DELOMATIC series, the DELOMATIC – 3 DGU2 stands out for its ability to offer tailor – made solutions that precisely meet the diverse demands of various industrial applications.

This system is engineered to integrate all the essential protection and control functions required in a wide range of power – related applications. It serves as a central hub, enabling seamless communication not only with other industrial systems but also with an optional graphic user interface, ensuring easy interaction for operators. In the context of automation systems, the DELOMATIC – 3 DGU2 plays a crucial role in optimizing the performance of generator plants. It maximizes the advantages of distributed power control, which is essential for maintaining stable power supply and efficient operation.

The DELOMATIC – 3 DGU2 can be used in multiple types of power plants. For instance, in marine applications, it provides reliable control for ship – board generators, ensuring continuous power supply for all on – board operations. In power stations, it helps in regulating the power generation process, enhancing the overall efficiency of the plant. In local co – generation and combined heat and power plants, it coordinates the generation and distribution of power and heat, making the most of available resources.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DELOMATIC – 3 DGU2 |

| Manufacturer | DEIF |

| Product Type | Multi – Function Control System for Generator Plants |

| Input Voltage | [Typically supports a range, e.g., 24V DC – 48V DC, check product manual for exact value] |

| Communication Protocol | Arc – network (a LAN network of token ring type), can interface with traditional serial communication standards like RS 232, RS422, and RS485 (Modbus RTU) through CM – 2 module |

| Connector Type | Removable connectors for all Delomatic modules |

| Physical Dimensions | Vary depending on rack size. For 84 TE rack: a = 426.7 mm, b = 465.1 mm, c = 483.0 mm; for 60 TE rack: a = 304.8 mm, b = 343.2 mm, c = 361.1 mm |

| Weight | For 84 TE rack: 3.5 kg (7.7 lb); for 60 TE rack: [weight value to be determined if different] |

| Operating Temperature | – 20°C to + 60°C |

| Humidity | 5 – 95% non – condensing |

| Protection Rating | [Specify if there is a particular IP rating, e.g., IP20 for dust protection in some standard configurations] |

| Input Channels | Multiple input channels depending on the configuration of input modules (e.g., with IPM – 1 module, can have up to 16 input channels per module, configurable as current, voltage, or binary input) |

| Output Channels | Multiple output channels depending on the configuration of output modules (e.g., with OPM – 1 module, can have 16 channel relay output; with AOM – 1 module, 8 – channel analog output) |

DELOMATIC – 3 DGU2

Key Features and Advantages

High Flexibility

The DELOMATIC – 3 DGU2 is extremely flexible, allowing for customization according to specific application requirements. It can be configured with a variety of special Delomatic modules. For example, the PSM – 1 power supply module provides power to all other modules in the DGU, ensuring stable operation. Different combinations of modules such as the IPM – 1 input module, OPM – 1 output module, and CRM – 1 current relay module can be selected to meet the unique input/output and protection needs of a particular generator plant.

Comprehensive Protection and Control

This system integrates all necessary protection and control functions. The CRM – 1 module can function as a short – circuit protection module, an earth – fault current protection module, or a differential current protection module, safeguarding the generator from various electrical faults. The SCM – 1 and SCM – 2 multi – function modules are responsible for functions like generator protection, breaker control, and measurement of three – phase values, ensuring the safe and efficient operation of the generator.

Easy Communication

It communicates effortlessly with other systems. Through the CM – 2 module, it can adapt to traditional serial communication standards such as RS 232, RS422, and RS485 (Modbus RTU), enabling seamless integration with existing industrial control networks. Additionally, it can communicate with an optional graphic user interface, providing operators with an intuitive way to monitor and control the system.

Redundant Design (in some configurations)

In certain setups, the DELOMATIC – 3 DGU2 may incorporate redundant components, such as power supplies. This redundancy ensures continuous operation even in the event of a component failure, enhancing the overall reliability of the generator control system. This is especially crucial in applications where uninterrupted power supply is essential, like in marine vessels or critical power – generation facilities.

DELOMATIC – 3 DGU2

Application Areas

Marine Applications

In the marine industry, the DELOMATIC – 3 DGU2 is widely used for controlling ship – board generators. It manages the start – stop sequence of generators, load sharing among multiple generators, and ensures the safe connection of shore power. For example, on large cruise ships, multiple generators need to be precisely controlled to meet the high – power demands of various onboard facilities such as lighting, air – conditioning, and entertainment systems. The DELOMATIC – 3 DGU2 can handle these complex operations, providing reliable power management and protection.

Power Stations

In power stations, whether they are fossil – fuel – based, hydro – electric, or wind – powered, the DELOMATIC – 3 DGU2 plays a vital role in optimizing power generation. It monitors and controls the performance of generators, ensuring they operate at peak efficiency. For instance, in a thermal power station, it can adjust the generator’s output based on the load demand, and at the same time, protect the generator from over – current, over – voltage, and other potential faults.

Local Co – generation and Combined Heat and Power Plants

These types of plants require efficient coordination between power and heat generation. The DELOMATIC – 3 DGU2 can manage the operation of generators in such a way that it maximizes the utilization of energy resources. It controls the power output to meet the electrical load while also ensuring that the heat generated as a by – product is effectively utilized, for example, for heating purposes in nearby buildings.

Industrial Manufacturing Facilities

Industrial manufacturing plants often have high – power demands and require reliable power supply. The DELOMATIC – 3 DGU2 can be used to control the generators that power these facilities. It can detect and respond to sudden changes in power demand, ensuring that the manufacturing processes are not disrupted due to power fluctuations. This is particularly important in industries such as automotive manufacturing, where continuous operation of production lines is crucial.

Related Products

- DEIF DELOMATIC – 3 DGU1: Similar to the DELOMATIC – 3 DGU2, but may have a different configuration of modules. For example, it might have a smaller number of input or output channels, making it suitable for less complex applications or those with lower I/O requirements.

- DEIF DELOMATIC – 4 DGU3: An upgraded version of the DELOMATIC series. It may offer enhanced functionality, such as more advanced communication capabilities or additional protection features. It could be used in applications where the requirements have evolved, and a more powerful control system is needed.

- DEIF CP – 1 Control Panel: This control panel is designed to work in conjunction with the DELOMATIC – 3 DGU2. It provides an operator interface, allowing for easy display and change of parameter settings, as well as the display of alarm messages and measured data.

- PSM – 1 Power Supply Module: A crucial component for the DELOMATIC – 3 DGU2 system. It supplies power to all the Delomatic modules in the DGU. Different versions of the PSM – 1 may exist, with variations in power output capacity to suit different system requirements.

- SCM – 1 Multi – Function Module: As part of the module family for the DELOMATIC – 3 DGU2, the SCM – 1 is responsible for key functions like generator protection and breaker control. There may be improved or specialized versions of the SCM – 1 available for specific applications or higher – end requirements.

DELOMATIC – 3 DGU2

Installation and Maintenance

Installation Preparation

Before installing the DELOMATIC – 3 DGU2, ensure that the power supply meets the specified voltage requirements. Check the physical location for installation, ensuring it is in an area with appropriate environmental conditions, such as within the recommended temperature and humidity ranges. Mount the DGU on a suitable rack, following the guidelines for the specific rack size (either 84 TE or 60 TE). Connect all the modules securely within the DGU, making sure that the removable connectors are properly fastened. When connecting to other systems, use the appropriate communication cables according to the selected communication protocol (e.g., for Arc – network, use the specified cabling; for RS 232/422/485, use the correct serial cables).

Maintenance Recommendations

Regularly inspect the DELOMATIC – 3 DGU2 for any signs of physical damage, such as loose connectors or damaged modules. Check the status indicators on the control panel and modules to ensure normal operation. Periodically update the firmware of the system, if available, to benefit from the latest features and bug fixes. Calibrate any sensors or measurement devices connected to the system at regular intervals to maintain accurate readings. In case of any alarms or malfunctions, refer to the detailed documentation provided by DEIF to diagnose and resolve the issues promptly.

Product Warranty

Our company provides a one – year quality warranty for the DEIF DELOMATIC – 3 DGU2. This warranty covers hardware failures caused by non – human factors. During the warranty period, if the product experiences any performance anomalies or functional failures, we will provide replacement services. Additionally, given our extensive experience in the industrial control parts distribution since 2007, we have a vast network of suppliers. This enables us to quickly respond to customers’ needs for scarce spare parts, even for discontinued models. We are committed to ensuring that our customers can rely on our services to keep their industrial systems running smoothly and continuously.

ABB PFEA113-20 3BSE028144R0020 DI module

ABB PP825A 3BSE042240R3 Module connector

GE IS420UCSBH3A DO module

GE SR469 469-P5-HI-A20-E Expansion rack

GE IS220PDIAH1A Network communication module

TRICONEX DO2401 7400209-030 servo

TRICONEX DO3401 Eddy current sensor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: