Description

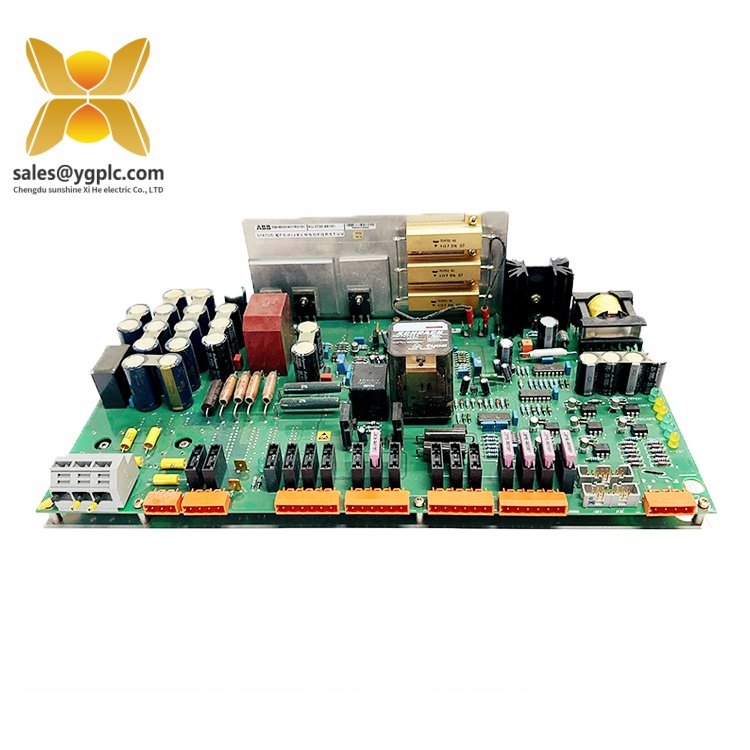

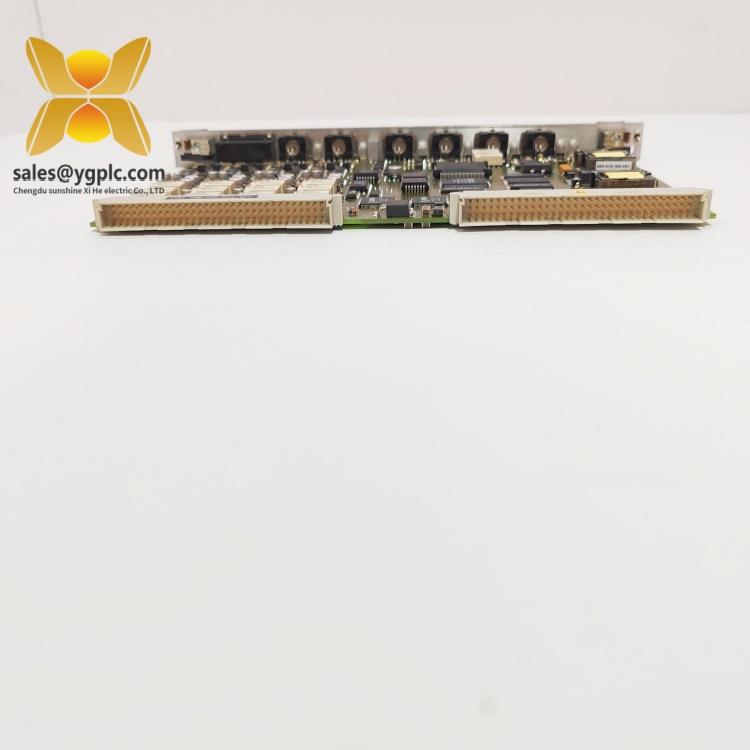

VIBRO-METER VM600 MPC4 200-510-064-034/200-610-100-034 Machinery Protection Card

Product Overview:VIBRO-METER VM600 MPC4

The VIBRO-METER VM600 MPC4 is a high-performance machinery protection card designed for critical rotating equipment health monitoring in industrial automation systems. As part of the VM600 Series, this module plays a pivotal role in ensuring the reliability and safety of turbines, compressors, and generators across industries such as oil & gas, power generation, and heavy manufacturing. By integrating with accelerometers, proximity probes, and speed sensors, the VM600 MPC4 delivers real-time measurements of vibration, speed, and position parameters, enabling predictive maintenance and preventing catastrophic failures.

Key functionalities of the VIBRO-METER VM600 MPC4 include signal conditioning, fault diagnostics, and alarm triggering. Each module supports 4 dynamic channels and 2 tachometer (speed) channels, all independently configurable to monitor parameters like radial vibration, axial displacement, and rotational speed with user-programmable alarm setpoints 78. The module’s compatibility with the VM600 ABE04X rack system allows seamless integration into existing monitoring frameworks, reducing downtime and maintenance costs. With its robust design (IP20-rated enclosure) and wide operating temperature range (-40°C to +85°C), the VM600 MPC4 ensures long-term performance in harsh industrial environments 8.

In automation ecosystems, the VM600 MPC4 serves as a critical interface between sensors and control systems, converting raw sensor data into actionable insights. Its dual-channel architecture supports redundant monitoring, enhancing system resilience in mission-critical applications. Whether deployed in standalone configurations or multi-module setups, this card ensures continuous operation and minimizes unplanned outages, making it indispensable for industries reliant on high-value rotating assets 27.

Technical Specifications:VIBRO-METER VM600 MPC4

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VM600 MPC4 200-510-064-034/200-610-100-034 |

| Manufacturer | VIBRO-METER |

| Product Type | Machinery Protection Card (Vibration and Speed Monitoring) |

| Input Channels | 4 dynamic channels, 2 tachometer channels |

| Measurement Range | Acceleration: 0.001–10 gfs; Speed: 0–10,000 rpm |

| Accuracy | ±2% (acceleration), ±1% (speed) |

| Power Supply | 24 V DC ±10% |

| Physical Dimensions | 100 mm (H) × 160 mm (W) × 80 mm (D) (estimated, please verify with datasheet) |

| Weight | 2.9 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in VM600 ABE04X frame, requires pairing with IOC4T card 7 |

| Communication | Proprietary interface, compatible with VM600 MPSX software |

| Certifications | CE, RoHS |

VM600 MPC4 200-510-064-034 200-610-100-034

Key Features and Advantages:VIBRO-METER VM600 MPC4

Multi-Channel Monitoring: The VM600 MPC4 supports 4 dynamic channels for vibration analysis and 2 tachometer channels for speed measurement, providing comprehensive insights into machinery health. Each channel can be individually configured to monitor specific parameters, ensuring tailored solutions for diverse applications 78.

High-Precision Diagnostics: With ±2% accuracy in acceleration measurements and ±1% in speed tracking, this module detects subtle anomalies in rotating equipment, such as bearing wear or shaft misalignment. Its advanced signal conditioning algorithms filter out noise, ensuring reliable data even in high-vibration environments 8.

Modular Design: The VM600 MPC4 integrates seamlessly with the VM600 Series rack system and pairs with the IOC4T card to form a complete monitoring solution, including sensor power supplies, buffered outputs, and relay interfaces 7. This modularity simplifies system expansion and upgrades.

Rugged Industrial Performance: Built with a corrosion-resistant enclosure and conformal coating, the VM600 MPC4 withstands extreme temperatures, humidity, and electromagnetic interference. Its shock and vibration resistance (IEC 60068-2-6) ensures reliable operation in offshore platforms, refineries, and other harsh settings 8.

Firmware Flexibility: The module supports firmware updates to address evolving application requirements, ensuring long-term compatibility with emerging technologies. Maintenance modes allow safe firmware upgrades without disrupting critical operations 9.

Alarm and Protection: User-configurable alarm thresholds trigger relay outputs for immediate corrective actions, preventing damage to equipment. The module’s diagnostic capabilities also identify sensor faults or communication errors, enabling proactive maintenance 78.

VM600 MPC4 200-510-064-034 200-610-100-034

Application Areas:VIBRO-METER VM600 MPC4

The VIBRO-METER VM600 MPC4 is widely deployed in industries where machinery reliability is paramount:

- Oil & Gas: Monitoring turbines, compressors, and pumps in offshore platforms and refineries to detect cavitation, misalignment, or bearing degradation.

- Power Generation: Ensuring the safe operation of steam turbines, gas turbines, and generators in thermal and nuclear power plants by tracking vibration and speed parameters.

- Metals & Mining: Safeguarding large-scale crushers, mills, and conveyor systems in mineral processing plants, reducing downtime during ore extraction and refining.

- Industrial Manufacturing: Protecting high-speed machinery like extruders, motors, and gearboxes in automotive, chemical, and pulp & paper facilities.

Specific applications include:

- Vibration Analysis: Detecting imbalance or resonance in rotating shafts to optimize maintenance schedules.

- Speed Monitoring: Ensuring synchronization of turbines and generators with grid frequency, enhancing energy efficiency.

- Condition-Based Maintenance: Providing real-time data for predictive analytics, minimizing unplanned outages and extending equipment lifespan 28.

By delivering actionable insights into machinery health, the VM600 MPC4 empowers maintenance teams to schedule proactive repairs, reduce operational costs, and extend equipment lifespan.

VM600 MPC4 200-510-064-034 200-610-100-034

Related Products:VIBRO-METER VM600 MPC4

- IOC4T Interface Card: Required for pairing with the VM600 MPC4, providing sensor power supplies, buffered outputs, and relay interfaces 7.

- XMV16 State Monitoring Card: Expands the VM600 system with 16 dynamic channels for advanced vibration analysis, complementing the MPC4 in large-scale applications 2.

- VM600/92 Communication Gateway: Enables integration with third-party systems via MODBUS or Ethernet, facilitating remote diagnostics and control 2.

- VM600 MPSX Software: Configures and manages the VM600 MPC4, offering real-time data visualization and alarm logging 7.

- 3300 XL Proximity Probes: Pair with the VM600 MPC4 for precise vibration and displacement measurements in critical machinery 2.

- VM600 ABE04X Rack Enclosure: Houses the MPC4 and other modules, providing a centralized monitoring platform

Installation and Maintenance

Installation Preparation:

Before installing the VIBRO-METER VM600 MPC4, ensure the VM600 ABE04X rack is properly grounded and ventilated. Verify compatibility with existing sensors and cabling, using shielded wires to minimize electromagnetic interference. Mount the module vertically within the rack, securing it with M4 screws. Pair the MPC4 with the IOC4T card and connect 24V DC power, following the wiring diagram provided in the technical manual 7. Use VM600 MPSX software to configure channel settings, calibration parameters, and alarm thresholds.

Before installing the VIBRO-METER VM600 MPC4, ensure the VM600 ABE04X rack is properly grounded and ventilated. Verify compatibility with existing sensors and cabling, using shielded wires to minimize electromagnetic interference. Mount the module vertically within the rack, securing it with M4 screws. Pair the MPC4 with the IOC4T card and connect 24V DC power, following the wiring diagram provided in the technical manual 7. Use VM600 MPSX software to configure channel settings, calibration parameters, and alarm thresholds.

Maintenance Recommendations:

- Routine Checks: Inspect the module quarterly for loose connections, corrosion, or physical damage. Clean the enclosure with a dry cloth to prevent dust accumulation.

- Calibration: Perform annual calibration using VIBRO-METER’s dedicated tools to ensure accurate sensor measurements. Document calibration results for compliance audits.

- Firmware Updates: Periodically update the module’s firmware to access new features and security patches, following the manufacturer’s guidelines. Ensure the module is in maintenance mode during updates to avoid operational disruptions 9.

- Spare Parts Management: Maintain a spare VM600 MPC4 module in a controlled environment (temperature: 10–30°C, humidity: 20–80% RH) to minimize downtime in case of failure. Store sensors and cabling separately to prevent damage.

VM600 MPC4 200-510-064-034 200-610-100-034

Product Warranty:VIBRO-METER VM600 MPC4

Our company provides a 12-month quality warranty for the VIBRO-METER VM600 MPC4, covering hardware defects under normal use. In the event of performance issues or functional failures, we offer prompt replacement services. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of rare or obsolete parts, supporting continuous industrial operations. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, ensuring seamless integration and long-term reliability.

For inquiries, contact our dedicated team via Whatsapp:+86 18859254943 or E-mail :sales@ygplc.com..

Foxboro H92 H92A049E0700 Data acquisition module

Yokogawa V1702 probe

ABB 3BHE023784R2530 PPD113B01-25-111000 Tachometer sensor

ABB 3BHE032025R0101 PCD235A101 modbus card

ABB G2000A5.7ST Power source

A-B 1336-QOUT-SP23A base

ABB 3BHE017628R0002 PPD115A02 SG579989013 exchange

Siemens 6DD2920-0AL0 DI module

Siemens 6DD2920-0AM0 AI card

Siemens 6DD2920-0BB0 Pulse encoder

HONEYWELL 51401497-100 FW25-92 Module connector

Bently 3500/44M 140734-03 03S Servo module

HONEYWELL EG1033AA EG1033AA01 261A1812P002 Control cabinet node unit

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: