Description

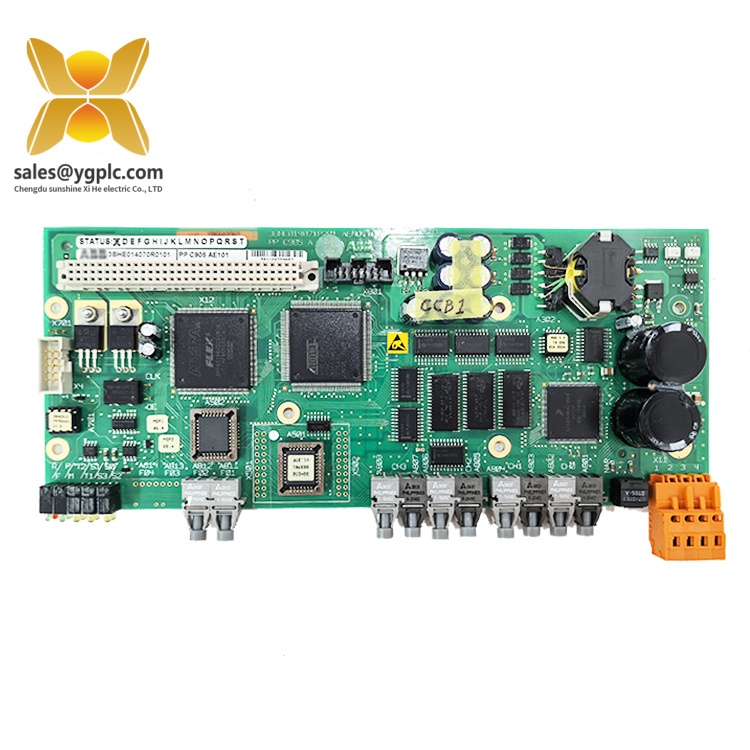

Product Overview :VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017

Technical Specifications :VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VM600 IOC4T 200-560-000-111 200-560-101-017 |

| Manufacturer | VIBRO-METER |

| Product Type | Quad Input/Output Controller |

| Input Channels | 4 (supports vibration, temperature, and process signals) |

| Output Signals | 4 x 4–20 mA analog, 4 x relay contacts |

| Power Supply | 24 V DC ±15% |

| Physical Dimensions | 133 mm (H) × 100 mm (W) × 200 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted (VM600 standard rack) |

| Communication | Serial interface (Modbus RTU via optional adapter) |

| Certifications | CE, ISO 10816-3, API 670 |

VM600 IOC4T 200-560-000-111 200-560-101-017

Key Features and Advantages :VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017

User-Configurable Alarms: Each channel features programmable warning and danger thresholds, with relay outputs for triggering alarms, shutdowns, or external control actions. This flexibility enables precise customization to match the specific protection requirements of different machinery types.

VM600 IOC4T 200-560-000-111 200-560-101-017

Application Areas :VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017

- Oil & Gas: Monitoring vibration and temperature in subsea pumps, pipeline compressors, and offshore turbines to detect bearing wear, misalignment, or cavitation, preventing costly disruptions in production.

- Power Generation: Ensuring the safe operation of steam turbines, gas generators, and hydroelectric equipment by continuously tracking critical parameters, the VM600 IOC4T supports grid stability and compliance with environmental regulations.

- Manufacturing: Protecting high-speed motors, conveyor systems, and robotic arms in automotive and food processing facilities by providing early warnings of mechanical degradation, reducing unplanned stoppages and maintenance costs.

- Marine & Offshore: Installed in ship engines and marine propulsion systems, the module withstands harsh marine environments (salt fog, humidity) while delivering accurate data for condition-based maintenance.

- Condition Monitoring Systems (CMS): Integrating with proximity probes and accelerometers to create comprehensive machinery health profiles.

- Safety Instrumented Systems (SIS): Providing fail-safe inputs for emergency shutdown sequences, ensuring compliance with IEC 61508 standards.

- Remote Monitoring Solutions: Transmitting real-time data to cloud-based platforms via Modbus-compatible gateways, enabling remote diagnostics and predictive analytics.

VM600 IOC4T 200-560-000-111 200-560-101-017

Related Products :VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017

- VM600 IOC8T: An 8-channel variant of the VM600 IOC4T, offering double the input/output capacity for large-scale monitoring applications.

- VM600 DP Display Processor: A companion module that provides local display and configuration for the VM600 IOC4T, featuring a graphical interface for real-time data visualization.

- VM600 COM Communication Module: Enables Ethernet/IP or Profibus connectivity for the VM600 IOC4T, facilitating integration with modern industrial networks.

- VM600 ACC Accelerometer Module: A dedicated input module for accelerometer signals, complementing the VM600 IOC4T in high-frequency vibration analysis.

- VM600 TMP Temperature Module: Specialized in RTD/thermocouple inputs, this module enhances the VM600 IOC4T’s capability to monitor thermal parameters.

- VM600 RACK Enclosure: A standardized rack system designed to house the VM600 IOC4T and other VM600 modules, ensuring centralized power management and signal routing.

- VM600 SPA Spare Module Adapter: Simplifies hot-swapping of the VM600 IOC4T during maintenance, minimizing downtime in critical systems.

Installation and Maintenance :VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017

Before installing the VM600 IOC4T, ensure the VM600 rack is properly grounded and powered. Verify that the environment meets temperature/humidity requirements (-40°C to +85°C, ≤95% RH non-condensing). Use shielded cables for sensor connections to minimize EMI, and secure the module in the rack using the provided mounting brackets. Configure channel parameters (e.g., sensor type, alarm thresholds) via the VM600 DP Display Processor or remote software tool.

- Routine Inspections: Monthly checks should include visual inspection of connections, LED status indicators, and temperature readings. Clean the module’s vents with compressed air to prevent dust accumulation that could affect heat dissipation.

- Calibration: Perform annual calibration using VIBRO-METER’s official tools to ensure measurement accuracy. Compare sensor inputs against known reference values and adjust offsets/gains as needed.

- Firmware Updates: Periodically update the module’s firmware to access new features or bug fixes, following the manufacturer’s guidelines. Back up configuration data before initiating updates to avoid data loss.

- Spare Parts Management: Store spare VM600 IOC4T modules in anti-static packaging at room temperature (10–30°C) with low humidity (20–60%). Regularly test spares in a simulated environment to ensure functionality.

VM600 IOC4T 200-560-000-111 200-560-101-017

Product Warranty :VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

VIBRO-METER VM600 204-040-100-012 Communication output interface component

VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013 Interface component

VIBRO-METER VM600 CPUM 200-595-067-114 DCS card module

Woodward 8237-1369 Remote module

Woodward 8237-1600 Main processor

ALSTOM CMP1838 TRVCO62345000 CP00005202 Pulse input

ABB PFEA113-20 3BSE028144R0020 DI module

ABB PFVO 102 Input pulse module

FOXBORO P0926GV FBM231 Digital output module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: