Description

Product Overview

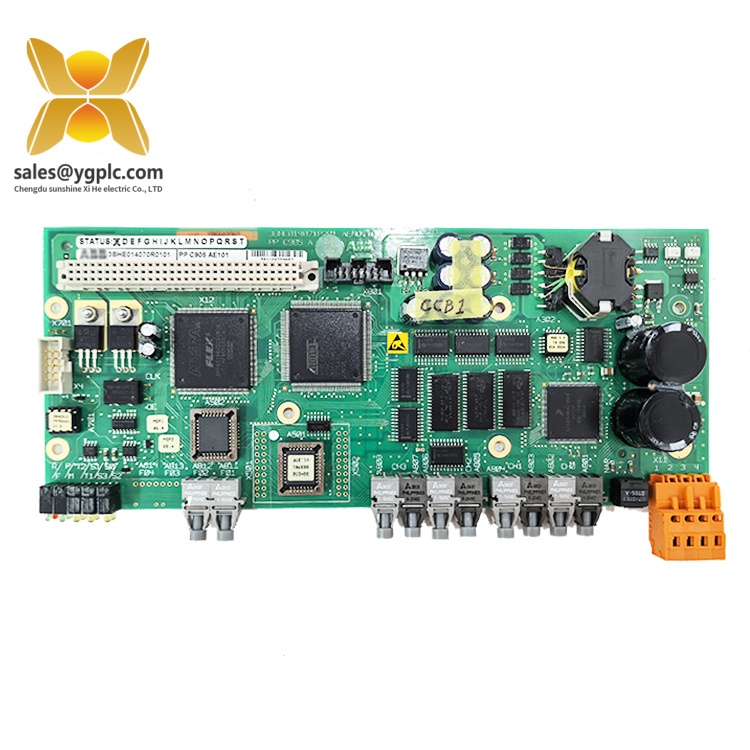

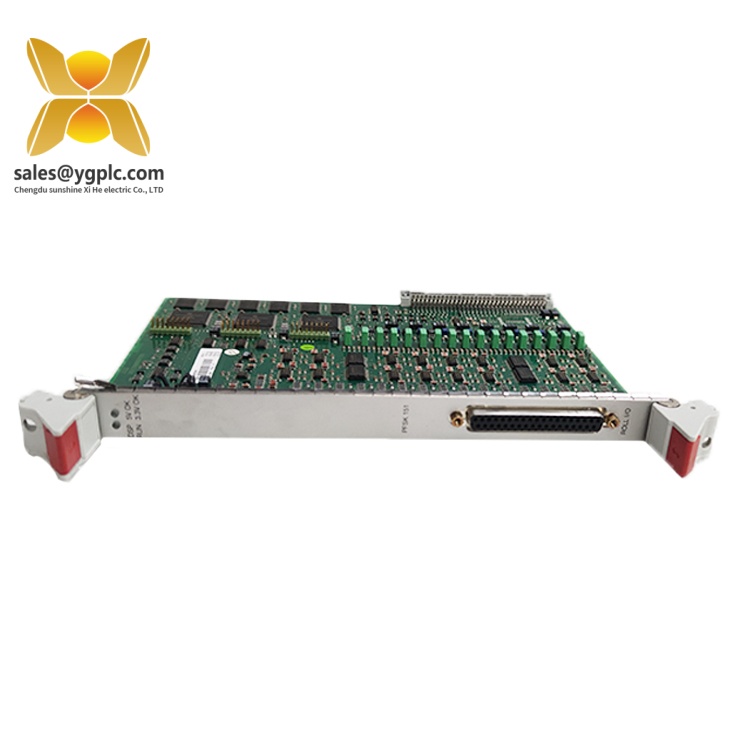

The VIBRO-METER MPC4 200-510-078-115 is a high-performance machinery protection card engineered by VIBRO-METER, a global leader in vibration monitoring and industrial condition monitoring solutions. As a core component of the VM600 Series modular machinery protection system, this card is designed to provide real-time monitoring and protection for critical rotating equipment, ensuring operational safety and minimizing downtime in industrial environments.

The VIBRO-METER MPC4 200-510-078-115 is a versatile module capable of simultaneously monitoring up to four dynamic channels (e.g., vibration, displacement) and two phase reference inputs. Its primary function is to convert raw sensor data into actionable insights, enabling early detection of mechanical anomalies such as unbalance, misalignment, or bearing wear. The module supports a wide range of input signals, including acceleration, velocity, and proximity measurements, making it compatible with various industrial sensors. By integrating the MPC4 200-510-078-115 into machinery protection systems, users can achieve predictive maintenance, optimize equipment performance, and comply with international safety standards.Whatsapp:+86 18859254943.

Within industrial automation frameworks, the VIBRO-METER MPC4 200-510-078-115 acts as a critical interface between field sensors and control systems. It processes analog signals in real time, applies advanced digital filtering algorithms, and generates alarm outputs for predefined threshold violations. Its modular design allows seamless integration into the VM600 Rack, supporting redundant configurations for high-availability applications. With robust diagnostic capabilities and a compact form factor, this module is ideal for industries where equipment reliability is paramount, such as power generation, oil and gas, and heavy manufacturing.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | MPC4 200-510-078-115 |

| Manufacturer | VIBRO-METER |

| Product Type | Machinery Protection Card (4 Dynamic Channels + 2 Phase Reference) |

| Input Signal Types | Acceleration (IEPE), velocity, displacement (proximity probes), TTL speed signals |

| Output Signals | 4-20 mA analog outputs, digital relay outputs (4 configurable alarms) |

| Power Supply | 12 V DC (±10%) |

| Power Consumption | ≤3 W |

| Operating Temperature | -20°C to +60°C (ambient) |

| Storage Temperature | -40°C to +85°C |

| Humidity Resistance | 10%–95% non-condensing |

| Physical Dimensions | 120 mm (width) × 110 mm (height) × 80 mm (depth) |

| Mounting Method | DIN-rail mountable (35 mm standard rail) |

| Communication Protocol | Modbus RTU (via optional communication modules) |

| Certifications | CE, UL, ISO 9001, IECEx (hazardous area compliance) |

| Signal Processing | Digital filtering, integration/differentiation, order tracking, peak detection |

| Diagnostic Features | Built-in self-test (BIST), sensor fault detection, LED status indicators |

MPC4 200-510-078-115

Main Features and Advantages

The VIBRO-METER MPC4 200-510-078-115 stands out for its advanced monitoring capabilities, rugged design, and adaptability to diverse industrial requirements.

Multi-Channel Monitoring and Precision Analysis

With support for four dynamic channels and two phase reference inputs, the MPC4 200-510-078-115 offers comprehensive coverage of critical machinery parameters. It processes signals with high accuracy, applying digital filtering and order tracking to isolate specific frequency components, such as blade passing frequencies in turbines or gear mesh vibrations in compressors. This precision enables operators to distinguish between normal and abnormal conditions, facilitating proactive maintenance strategies.

Modular System Integration

As part of the VM600 Series, the MPC4 200-510-078-115 leverages a scalable rack-based architecture, allowing users to

mix and match modules for vibration monitoring, speed measurement, and process control. Its plug-and-play design simplifies installation and expansion, while redundant power supplies ensure continuous operation in mission-critical environments.

Advanced Diagnostic Capabilities

The module incorporates built-in self-test (BIST) functionality and real-time sensor fault detection, alerting operators to issues such as open circuits or signal drift. LED indicators on the front panel provide instant status feedback, while diagnostic data can be accessed remotely via Modbus RTU for centralized monitoring. This reduces troubleshooting time and enhances system reliability.Whatsapp:+86 18859254943.

Wide Environmental Tolerance

Engineered for harsh conditions, the MPC4 200-510-078-115 operates reliably across extreme temperatures and resists vibration, shock, and electromagnetic interference. Its rugged enclosure and conformal coating protect against dust, moisture, and corrosive atmospheres, making it suitable for offshore platforms, chemical plants, and other challenging industrial settings.

Compliance with International Standards

Certified to CE, UL, and IECEx standards, the MPC4 200-510-078-115 ensures compliance with global safety and quality requirements. Its hazardous area certification (IECEx) allows deployment in Zone 1/21 environments, providing a secure solution for industries handling flammable gases or dust.

MPC4 200-510-078-115

Application Areas

The VIBRO-METER MPC4 200-510-078-115 is widely used in industries where machinery health monitoring is critical to operational continuity:

Power Generation

In steam and gas turbine plants, the MPC4 200-510-078-115 monitors vibration levels, shaft displacement, and bearing temperatures to prevent catastrophic failures. It supports predictive maintenance programs by detecting early signs of imbalance or misalignment, reducing downtime and extending equipment lifespan.

Oil and Gas

Within offshore rigs and refineries, the module safeguards pumps, compressors, and motors by analyzing vibration patterns and speed signals. It ensures compliance with safety protocols in explosive environments, providing real-time data for process optimization and emergency shutdown systems.

Heavy Manufacturing

In steel mills and cement plants, the MPC4 200-510-078-115 monitors conveyor belts, crushers, and mixers to detect mechanical wear or loose components. Its ability to track rotational speed and phase enables precise alignment adjustments, improving production efficiency and reducing material waste.Whatsapp:+86 18859254943.

Chemical and Pharmaceutical

In chemical processing units, the module monitors agitators, reactors, and centrifuges to ensure stable operation. It detects Abnormal vibration caused by process imbalances or faulty seals, preventing product contamination and ensuring regulatory compliance in cleanroom environments.

Mining and Minerals

In underground mining operations, the MPC4 200-510-078-115 monitors ventilation systems, crushers, and haul trucks. Its robust design withstands dust and vibration, providing reliable data for equipment health management in remote or harsh locations.

MPC4 200-510-078-115

Related Products

The VIBRO-METER MPC4 200-510-078-115 is part of a comprehensive ecosystem of machinery protection solutions:

- VIBRO-METER IOC4T: An input/output card 配套使用 with the MPC4, providing buffered sensor outputs and analog signal conditioning for enhanced measurement accuracy.

- VIBRO-METER IRC4: A relay interface card that expands the MPC4’s alarm output capabilities, supporting up to 16 relay contacts for shutdown or notification purposes.

- VIBRO-METER RLC16: A relay logic card that enables complex interlocking and control sequences, integrating with the MPC4 for advanced machinery protection.

- VIBRO-METER MPC4 MK2: An upgraded version of the MPC4, offering higher processing power and additional communication interfaces for Industry 4.0 applications.

- VIBRO-METER VM600 Rack: A 19-inch rack system that houses the MPC4 and other VM600 modules, providing a centralized platform for machinery monitoring and control.

- VIBRO-METER VIBRO-SIGHT Software: A diagnostic software suite that interfaces with the MPC4, enabling real-time data visualization, trend analysis, and report generation.

Installation and Maintenance

Installation Preparations:

Before installing the VIBRO-METER MPC4 200-510-078-115, ensure the power supply is disconnected and the control panel is properly grounded. Verify that the module’s voltage and signal specifications match your system requirements. Mount the module on a 35 mm DIN rail within the VM600 Rack, ensuring adequate ventilation. Connect sensor inputs to the rear terminals and configure alarm thresholds using the VIBRO-SIGHT Software or Modbus RTU interface. Finally, apply power and check the LED indicators to confirm normal operation.

Before installing the VIBRO-METER MPC4 200-510-078-115, ensure the power supply is disconnected and the control panel is properly grounded. Verify that the module’s voltage and signal specifications match your system requirements. Mount the module on a 35 mm DIN rail within the VM600 Rack, ensuring adequate ventilation. Connect sensor inputs to the rear terminals and configure alarm thresholds using the VIBRO-SIGHT Software or Modbus RTU interface. Finally, apply power and check the LED indicators to confirm normal operation.

Maintenance Recommendations:

Regularly inspect the MPC4 200-510-078-115 for loose connections, physical damage, or dust accumulation. Clean the module with a dry, anti-static cloth to maintain optimal heat dissipation. Monitor the LED indicators for fault signals (e.g., red light for sensor failure) and use the diagnostic software to review system logs. Periodically recalibrate sensors and update firmware to ensure compatibility with the latest system enhancements. For complex issues, consult VIBRO-METER technical documentation or contact our support team for assistance.

Regularly inspect the MPC4 200-510-078-115 for loose connections, physical damage, or dust accumulation. Clean the module with a dry, anti-static cloth to maintain optimal heat dissipation. Monitor the LED indicators for fault signals (e.g., red light for sensor failure) and use the diagnostic software to review system logs. Periodically recalibrate sensors and update firmware to ensure compatibility with the latest system enhancements. For complex issues, consult VIBRO-METER technical documentation or contact our support team for assistance.

MPC4 200-510-078-115

Product Assurance

Our company provides a one-year quality warranty for the VIBRO-METER MPC4 200-510-078-115, covering hardware failures due to non-human factors. During the warranty period, we will promptly replace any module experiencing performance anomalies or functional issues. For discontinued models or urgent requirements, our global supply chain network ensures fast access to scarce spare parts, minimizing downtime for your critical systems. With 17 years of expertise in industrial control distribution, we are committed to delivering reliable products and support, ensuring your operations benefit from the MPC4 200-510-078-115’s advanced monitoring capabilities and our dedicated service. Trust us to be your partner in maintaining safe, efficient, and compliant industrial automation systems.E-mail :sales@ygplc.com.

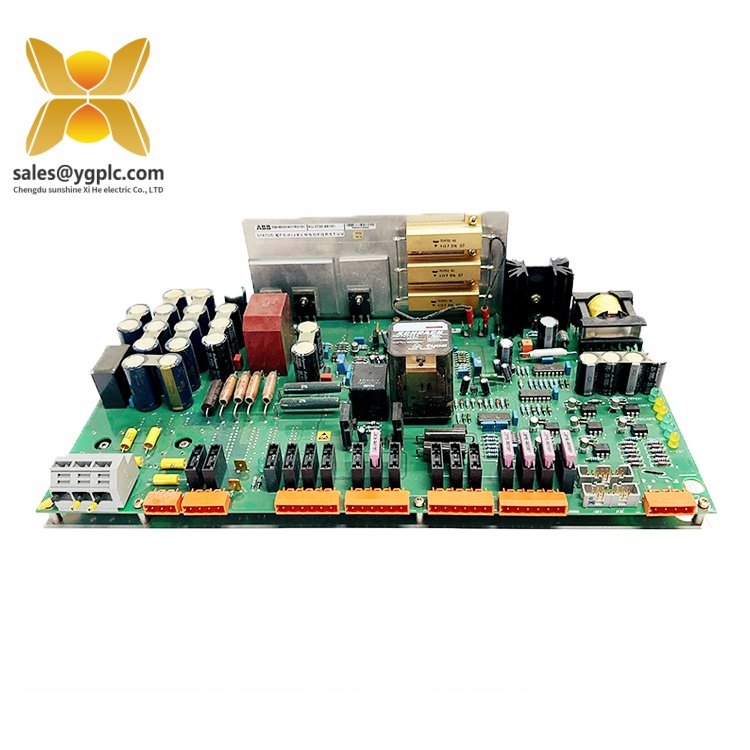

ABB PPC905AE101 3BHE014070R0101 controller

ABB DSPU131 3BSE000355R1 Inverter operating panel

ABB GDD471A001 AI/AO/DI/DO module

ABB UAD149A0011 Servo valve

ABB NAIO-03 Optical fiber interface board

GE SR469 469-P5-HI-A20-E Interface component

GE IS220PDIAH1A DCS card module

TRICONEX DO2401 7400209-030 servo

TRICONEX DO3401 Eddy current sensor

TRICONEX D28799-005 monitor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: