Description

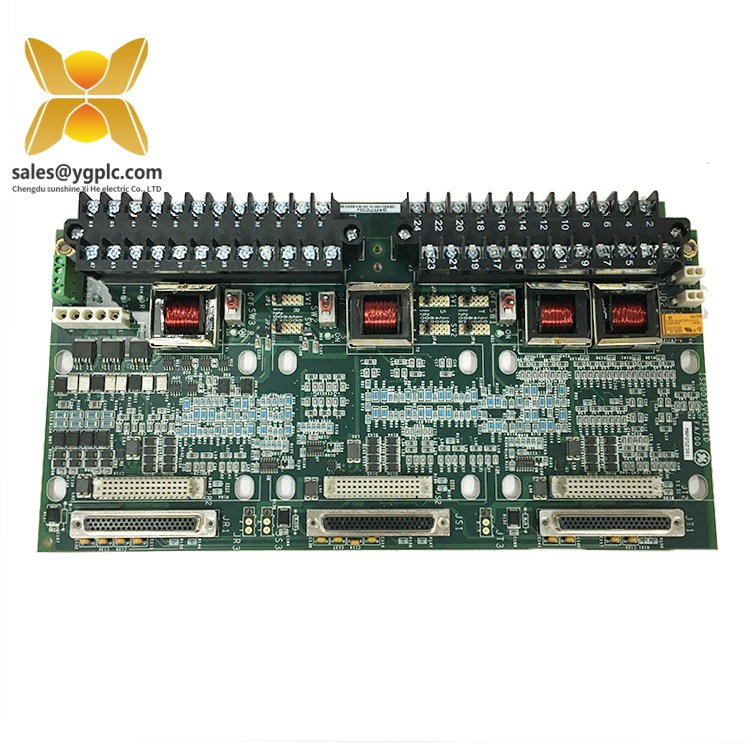

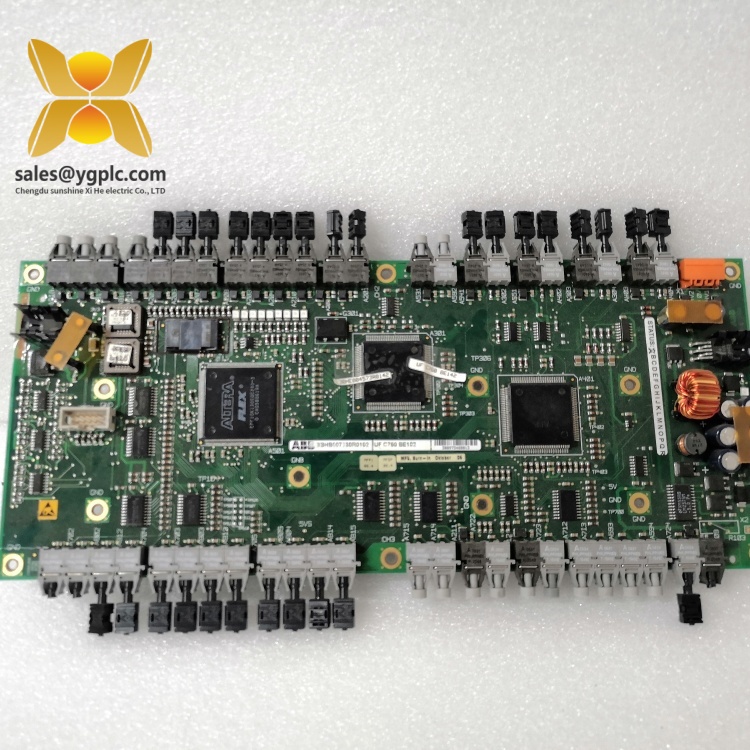

Product Overview: ABB UFC760BE142 3BHE004573R0142

The ABB UFC760BE142 3BHE004573R0142 is a cutting-edge thyristor power controller engineered to deliver precise, reliable power regulation for industrial heating and thermal processing systems. As a flagship model in ABB’s UFC760 series, it merges rugged thyristor technology with intelligent control logic to optimize energy usage while maintaining strict temperature and power output stability. Designed for medium to high-load applications, the ABB UFC760BE142 3BHE004573R0142 excels in environments where consistent thermal performance directly impacts product quality, such as manufacturing lines, industrial furnaces, and process heating systems. Its robust build and flexible integration capabilities make it a go-to solution for industries prioritizing efficiency, durability, and precise control.

Technical Specifications — ABB UFC760BE142 3BHE004573R0142

| Parameter | Specification |

|---|---|

| Input Voltage | 3-phase AC 380–480 V ±10%, 50/60 Hz |

| Output Current Rating | 142 A (continuous), 284 A (peak, 10-second duration) |

| Control Signal Inputs | 0–10 V DC, 4–20 mA DC, digital pulse (5–24 V DC) |

| Control Modes | Phase-angle control, burst-firing control |

| Communication Interfaces | RS485 (Modbus RTU), optional Profibus DP |

| Digital I/O | 2 digital inputs (control enable, mode select), 1 digital output (status alarm) |

| Protection Features | Overcurrent, overtemperature, short circuit, undervoltage, phase loss |

| Operating Temperature | -10°C to +50°C (ambient, with adequate ventilation) |

| Storage Temperature | -25°C to +70°C |

| Dimensions (W×H×D) | 120 mm × 220 mm × 180 mm (DIN-rail mountable) |

| Cooling Method | Natural convection (standard), forced air (optional) |

| Certifications | CE, UL 508C, IEC 60947-4-3, RoHS compliant |

UFC760BE142 3BHE004573R0142

Related products: ABB UFC760BE142 3BHE004573R0142

- ABB UFC760BE070 3BHE004573R0070: A 70 A variant of the UFC760 series, ideal for lighter heating loads in small to medium-sized equipment.

- ABB AC500-eCo PLCs: Compact programmable logic controllers that seamlessly interface with ABB UFC760BE142 3BHE004573R0142 for centralized automation control.

- ABB TTH310 Temperature Transmitters: High-accuracy RTD/thermocouple transmitters providing real-time temperature feedback to ABB UFC760BE142 3BHE004573R0142 systems.

- ABB CP635 HMI Panels: 7-inch touchscreen interfaces for intuitive monitoring and parameter adjustment of ABB UFC760BE142 3BHE004573R0142 operations.

- ABB AF Contactor Series: Heavy-duty contactors designed to handle main power switching in setups using ABB UFC760BE142 3BHE004573R0142.

- ABB PSE Power Supplies: Reliable 24 V DC power supplies ensuring stable auxiliary power for ABB UFC760BE142 3BHE004573R0142 control circuits.

Main features and advantages: ABB UFC760BE142 3BHE004573R0142

- Precision Power Regulation: The ABB UFC760BE142 3BHE004573R0142 leverages advanced phase-angle and burst-firing algorithms to maintain output accuracy within ±1% of the setpoint. This level of precision is critical for processes like metal annealing, where temperature uniformity directly affects material strength and ductility.

- High Current Handling: With a continuous output of 142 A and peak capacity of 284 A, it reliably powers large heating elements—such as those in industrial ovens or extrusion machines—without voltage drops or performance degradation.

- Flexible Control Compatibility: Accepts standard analog signals (0–10 V, 4–20 mA) and digital inputs, making it easy to integrate with existing PLCs, temperature controllers, or HMI systems, reducing retrofitting costs.

- Comprehensive Safety Protection: Built-in safeguards against overcurrent, overtemperature, phase loss, and short circuits automatically shut down the module in fault conditions, protecting both the controller and connected equipment from damage.

- Energy Efficiency: Optimized firing sequences minimize harmonic distortion (THD < 10% at full load) and reduce energy waste, lowering operational costs while complying with international energy standards (e.g., IEC 61000).

- Seamless Network Integration: Supports Modbus RTU as standard and Profibus DP as an option, enabling remote monitoring, parameter adjustment, and data logging for predictive maintenance and process optimization.

- Space-Saving Design: DIN-rail mountable with a compact footprint (120 mm width), it fits easily into crowded control cabinets, ideal for facilities with limited space.

- User-Friendly Operation: Front-panel potentiometers, LED status indicators (power, run, alarm), and a clear labeling scheme simplify on-site setup and troubleshooting, even for technicians with basic training.

UFC760BE142 3BHE004573R0142

Installation and maintenance: ABB UFC760BE142 3BHE004573R0142

Installing the ABB UFC760BE142 3BHE004573R0142 is designed for efficiency, starting with secure DIN-rail mounting in a control cabinet. Prior to installation, verify that the input voltage matches the 380–480 V AC specification and that the mounting location offers adequate ventilation—natural convection works for most environments, but forced air cooling is recommended if ambient temperatures exceed 40°C.

Wiring must follow ABB guidelines: power connections (3-phase input) use copper cables rated for ≥142 A, control signals (analog/digital) are shielded to prevent electromagnetic interference, and communication lines (RS485) include 120Ω termination resistors at both ends. Initial configuration is flexible: basic settings (e.g., control signal range, firing mode) can be adjusted via front-panel knobs, while advanced parameters (ramp rates, alarm thresholds) are set using ABB’s free configuration software via the RS485 port.

Routine maintenance is minimal but critical for longevity:

- Monthly: Inspect power and signal connections for tightness; clean ventilation grilles to prevent dust buildup.

- Quarterly: Check LED indicators for fault codes; verify control signal accuracy with a multimeter.

- Annually: Update firmware via the communication interface to access performance improvements; inspect thyristor heat sinks for corrosion.

In case of alarms, the module’s built-in diagnostics (displayed via LEDs) quickly identify issues like overcurrent or sensor failure, reducing troubleshooting time.

Application fields: ABB UFC760BE142 3BHE004573R0142

The ABB UFC760BE142 3BHE004573R0142 is trusted across industries requiring precise, high-power heating control:

- Metal Processing: Regulates temperature in annealing furnaces, heat treatment ovens, and hot rolling mills, ensuring consistent material hardness and reducing defects.

- Plastic Manufacturing: Controls heating in injection molding machines, extruders, and blow molding systems, maintaining optimal melt flow rates for uniform part quality.

- Glass Production: Manages temperature in glass melting furnaces and annealing lehrs, critical for preventing thermal stress and ensuring glass clarity.

- Food and Beverage: Powers heating elements in pasteurizers, sterilizers, and cooking kettles, ensuring compliance with food safety standards (e.g., FDA, EU 10/2011).

- Chemical Processing: Controls reactor heating in batch processes, enabling precise temperature ramps for chemical synthesis and avoiding unwanted side reactions.

- Ceramics Industry: Regulates kiln temperatures during firing cycles, ensuring ceramic products achieve the desired density, strength, and glaze finish.

- Automotive Manufacturing: Used in paint curing ovens and component heat treatment lines, ensuring consistent coating adhesion and part durability.

UFC760BE142 3BHE004573R0142

Product guarantee: ABB UFC760BE142 3BHE004573R0142

The ABB UFC760BE142 3BHE004573R0142 is backed by a 2-year manufacturer’s warranty covering defects in materials and workmanship under normal operating conditions. During this period, ABB provides free repair or replacement of faulty modules, with fast turnaround times to minimize production downtime.

For extended support, ABB offers customizable service plans that include:

- Preventive maintenance checks by certified engineers.

- Priority technical support via phone or email.

- Access to genuine spare parts and firmware updates.

- On-site troubleshooting and system optimization.

To inquire about product availability, technical details, or service plans, contact us via WhatsApp +86 18859254943 or visit www.ygplc.com for datasheets, installation guides, and application case studies.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: