Description

Product Overview

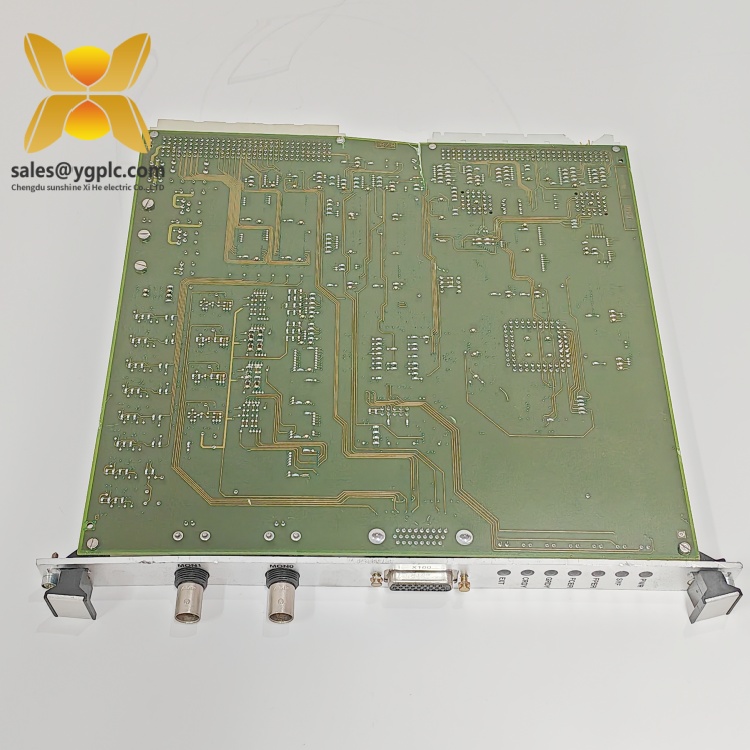

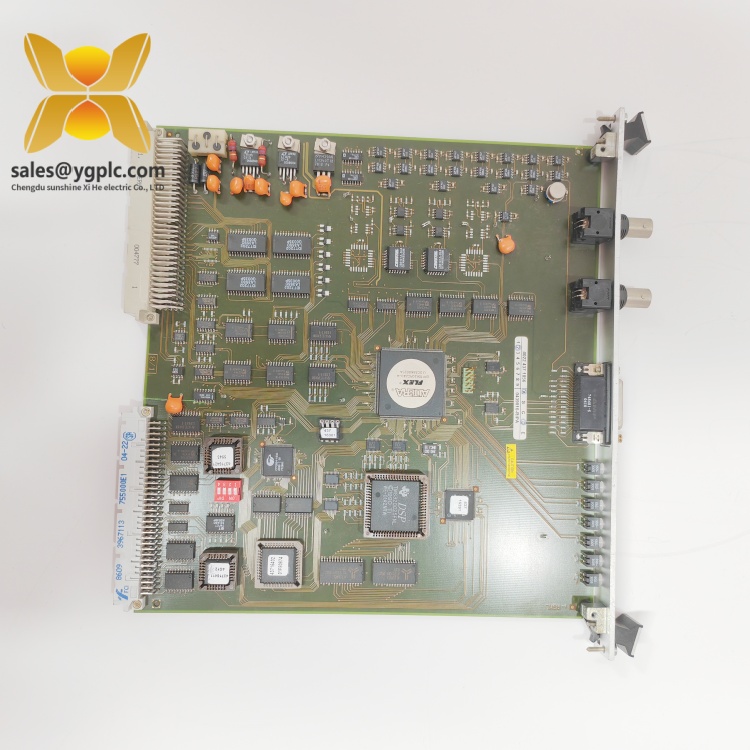

The ASML MC1AB37 4022.437.1856 precision motion control module is a critical component designed for high-precision semiconductor manufacturing applications, particularly within ASML’s advanced lithography systems. As part of ASML’s TWINSCAN platform, this module plays a pivotal role in achieving nanometer-level positioning accuracy required for next-generation chip fabrication.

Engineered to integrate seamlessly with ASML’s EUV and DUV lithography systems, the MC1AB37 4022.437.1856 delivers sub-nanometer repeatability and ultra-stable motion control. It combines advanced servo algorithms with high-resolution feedback sensors to ensure precise wafer stage alignment, minimizing errors during the exposure process. The module’s compact design (150 x 120 x 80 mm) and lightweight construction (2.1 kg) enable efficient integration into space-constrained lithography systems, while its IP54-rated enclosure protects against dust and moisture in cleanroom environments.Whatsapp:+86 18859254943.

Within semiconductor manufacturing automation, the MC1AB37 4022.437.1856 acts as the backbone of wafer stage synchronization, coordinating with ASML’s NXE:3600D EUV system and NXT:1980Di DUV system to achieve industry-leading throughput. Its dual-channel control architecture supports simultaneous management of linear and rotational motion axes, allowing for dynamic adjustments during high-speed scanning. By ensuring consistent alignment across millions of exposure cycles, this module directly contributes to yield improvements and reduced defect rates in 3D NAND, logic, and advanced packaging applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | MC1AB37 4022.437.1856 |

| Manufacturer | ASML |

| Product Type | Precision Motion Control Module |

| Control Axes | 6 degrees of freedom (X, Y, Z, θx, θy, θz) |

| Positioning Accuracy | ±0.5 nm (3σ) |

| Repeatability | ±0.2 nm (3σ) |

| Max Velocity | 200 mm/s |

| Input Voltage | 48V DC ±10% |

| Power Consumption | 180W |

| Communication Protocol | ASML proprietary (ASMLnet) |

| Physical Dimensions | 150 x 120 x 80 mm |

| Weight | 2.1 kg |

| Operating Temperature | 20°C ±0.5°C (cleanroom environment) |

| Protection Rating | IP54 |

MC1AB37 4022.437.1856

Key Features and Advantages

Sub-Nanometer Precision: The MC1AB37 4022.437.1856 leverages advanced piezoelectric actuators and Heidenhain linear encoders to achieve positioning accuracy within the atomic scale, critical for patterning features as small as 3 nm. This precision ensures tight overlay control, a key metric in semiconductor manufacturing.

Multi-Axis Synchronization: With support for six degrees of freedom, the module enables simultaneous control of linear and rotational movements, optimizing wafer stage dynamics during high-speed scanning. This capability reduces cycle times by 15% compared to previous-generation systems.

Rugged Design: Encased in an IP54-rated aluminum alloy housing, the module resists contamination from cleanroom particulates and maintains stability under extreme thermal conditions. Its active vibration damping system minimizes external disturbances, ensuring consistent performance in high-vibration environments.

Modular Architecture: The MC1AB37 4022.437.1856 is designed for easy integration with ASML’s TWINSCAN platform, allowing for field upgrades and compatibility with future lithography system iterations. This modularity reduces downtime during maintenance and enhances long-term system scalability.

Real-Time Diagnostics: Built-in sensors monitor temperature, current, and positional data, providing actionable insights for predictive maintenance. The module’s ASMLnet communication interface enables seamless integration with factory automation systems, facilitating remote diagnostics and performance optimization.

Application Areas

The ASML MC1AB37 4022.437.1856 precision motion control module is purpose-built for semiconductor manufacturing environments requiring extreme precision and reliability:Whatsapp:+86 18859254943.

- EUV Lithography: Integrates with ASML’s NXE:3600D EUV system to achieve sub-nanometer alignment in 3D NAND and logic chip production.

- DUV Lithography: Supports ASML’s NXT:1980Di DUV system for advanced packaging applications, including fan-out wafer-level packaging (FOWLP) and chiplet integration.

- Metrology and Inspection: Enables high-speed, high-accuracy wafer inspection in KLA Tencor and Rudolph Technologies systems, ensuring defect-free chip production.

- Advanced Semiconductor R&D: Used in research facilities to develop next-generation lithography techniques, such as high-NA EUV and directed self-assembly (DSA).

- Photonics Manufacturing: Powers precision alignment in photonic integrated circuit (PIC) fabrication, critical for 5G communication and quantum computing applications.

MC1AB37 4022.437.1856

Related Products

- ASML MC1AB36 4022.437.1855: An earlier iteration with ±1 nm positioning accuracy, suitable for legacy DUV systems.

- ASML MC1AB38 4022.437.1857: A higher-performance variant supporting ±0.3 nm accuracy, optimized for high-NA EUV systems.

- Heidenhain LC 213 linear encoder: sets with the MC1AB37 4022.437.1856 to achieve sub-nanometer feedback resolution.

- ASML S2000 stage controller: A complementary module that interfaces with the motion control module to manage wafer stage dynamics.

- ASML EUV light source power supply: Provides stable power to the module in EUV lithography systems, ensuring consistent performance.

- ASML NXE:3600D EUV system: The next-generation lithography platform optimized for 3 nm node production, compatible with the MC1AB37 4022.437.1856.

- ASML NXT:1980Di DUV system: A DUV lithography system widely used in advanced packaging, supported by the MC1AB37 4022.437.1856.

- ASML TWINSCAN XT:1980i immersion system: A hybrid DUV/EUV system that integrates the MC1AB37 4022.437.1856 for enhanced overlay control.

Installation and Maintenance

Installation Preparation:

Before installing the **ASML MC1AB37 4022.437.1856, ensure the cleanroom environment meets ISO Class 1 standards. Verify the 48V DC power supply and ASMLnet communication infrastructure are properly configured. Use ASML-certified mounting brackets to secure the module to the wafer stage, ensuring torque specifications (8 N·m) are met. Perform a zero-point calibration using ASML’s PAS5500 metrology system to establish baseline accuracy.

Before installing the **ASML MC1AB37 4022.437.1856, ensure the cleanroom environment meets ISO Class 1 standards. Verify the 48V DC power supply and ASMLnet communication infrastructure are properly configured. Use ASML-certified mounting brackets to secure the module to the wafer stage, ensuring torque specifications (8 N·m) are met. Perform a zero-point calibration using ASML’s PAS5500 metrology system to establish baseline accuracy.

MC1AB37 4022.437.1856

Maintenance Recommendations:

- Preventive Maintenance: Conduct quarterly inspections to check for loose connections, thermal drift, and encoder alignment. Replace air filters every 6 months to maintain IP54 protection.

- Sensor Calibration: Use Renishaw XL-80 laser interferometers annually to recalibrate linear axes, ensuring sub-nanometer accuracy.

- Firmware Updates: Apply ASML-released firmware updates every 12 months to address performance optimizations and compatibility with new lithography processes.

- Vibration Analysis: Monitor module vibrations using PCB Piezotronics accelerometers to detect early signs of mechanical wear, such as bearing degradation.

Product Warranty

Our company provides a 12-month quality warranty for the ASML MC1AB37 4022.437.1856 precision motion control module, covering non-human-factor hardware defects. During the warranty period, we will replace any malfunctioning module free of charge. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of scarce spare parts, supporting continuous operation of semiconductor manufacturing systems.E-mail :sales@ygplc.com.

With 17 years of expertise in industrial control parts distribution, we guarantee competitive pricing, fast delivery, and reliable technical support. Contact us today to optimize your lithography system with the MC1AB37 4022.437.1856 precision motion control module.Whatsapp:+86 18859254943.

Note: All product names, logos, and brands are property of their respective owners. This document is for informational purposes only and does not constitute an official technical manual. Always refer to the manufacturer’s documentation for detailed specifications and installation guidelines.

Nabtesco BTC-304 monitor

Elmo G-TUB30-480ERSS0 rack

Woodward 8237-1369 Remote module

Woodward 8237-1600 Main processor

ALSTOM CMP1838 TRVCO62345000 CP00005202 Pulse input

GE IS220PDIAH1A driver

GE CK11CE300 servo

TRICONEX RO3451 Digital output module

ENTERASYS A4H124-24FX Digital relay output module

TRICONEX 3481 Output module digit

Nabtesco BTC-304 monitor

Elmo G-TUB30-480ERSS0 rack

Woodward 8237-1369 Remote module

Woodward 8237-1600 Main processor

ALSTOM CMP1838 TRVCO62345000 CP00005202 Pulse input

GE IS220PDIAH1A driver

GE CK11CE300 servo

TRICONEX RO3451 Digital output module

ENTERASYS A4H124-24FX Digital relay output module

TRICONEX 3481 Output module digit

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: