Description

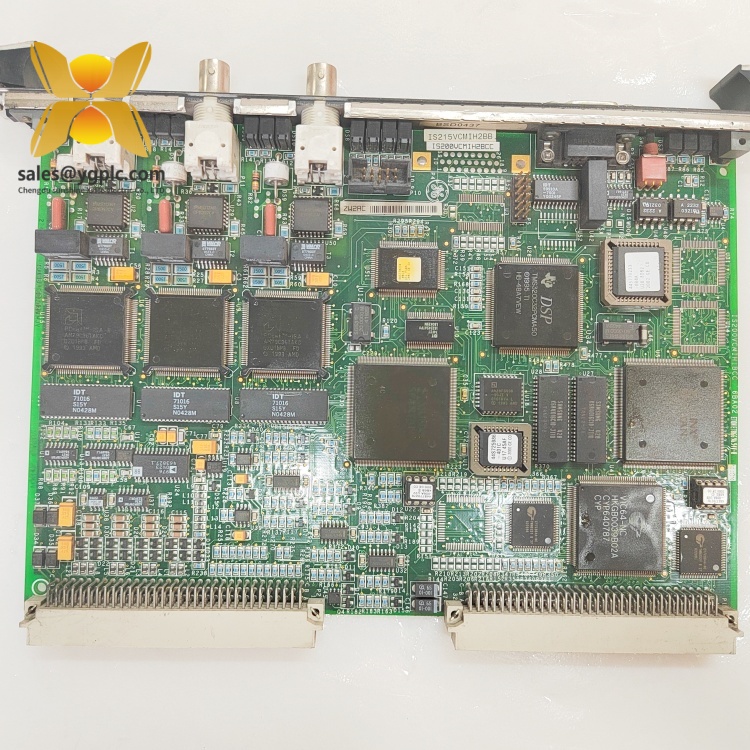

GE IS215VCMIH2BB VMEbus Communication Interface Card

Product Overview

The GE IS215VCMIH2BB is a mission-critical VMEbus Communication Interface Card designed for GE’s Mark VI Speedtronic series, specifically engineered to manage high-speed data exchange in gas turbine control systems and industrial automation ecosystems. As a VMEbus Master Controller, this module serves as the backbone for communication between the system’s central processing unit (CPU) and I/O boards, while also interfacing with GE’s proprietary IONET control network. The IS215VCMIH2BB is part of the IS215 Series, which prioritizes reliability, ruggedness, and seamless integration in demanding industrial environments such as power generation, oil & gas, and aerospace.

Featuring a 6U VMEbus form factor (167.6 mm × 233.4 mm × 44.5 mm) and weighing 0.8 kg, the GE IS215VCMIH2BB combines a Texas Instruments TMS320C32 32-bit digital signal processor with 256K × 32 SRAM and dual-port memory architecture to enable real-time data transfer and synchronization. Its front panel includes three IONET Ethernet ports (10Base2, 10 Mbps) and one RS-232 serial port, supporting communication with local and remote I/O racks, PLCs, and external control systems. The module’s VMEbus interface (32-bit, 33 MHz) ensures high-speed data exchange, while built-in diagnostics monitor internal power supplies (+5V, +12V, +15V, +28V) and trigger alarms for voltage deviations (customizable thresholds, typically ±3.5% for most rails) 47.

In industrial automation systems, the IS215VCMIH2BB acts as the communication hub, enabling redundant control configurations (e.g., simplex or triple modular redundancy, TMR) and managing board identification (IDs) for all components within its VMEbus rack. Its rugged design, with conformal coating and compliance with MIL-STD-810G for vibration, shock, and temperature extremes (-40°C to +70°C), ensures reliable operation in harsh environments such as offshore platforms, military vehicles, and heavy manufacturing facilities. By facilitating seamless integration between legacy I/O modules and modern control networks, this card bridges the gap between traditional and cutting-edge automation technologies.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS215VCMIH2BB |

| Manufacturer | GE |

| Product Type | VMEbus Communication Interface Card / VMEbus Master Controller |

| Series | Mark VI Speedtronic |

| Form Factor | 6U VMEbus (167.6 mm × 233.4 mm × 44.5 mm) |

| Weight | 0.8 kg |

| Processor | Texas Instruments TMS320C32 32-bit DSP |

| Memory | 256K × 32 SRAM, dual-port memory for real-time data exchange |

| Communication Interfaces | Three IONET Ethernet ports (10Base2, 10 Mbps), one RS-232 serial port |

| Bus Interface | VMEbus (32-bit, 33 MHz) |

| Power Requirements | +5V, +12V, +15V, +28V DC (monitored with customizable alarm thresholds) |

| Operating Temperature | -40°C to +70°C |

| Certifications | MIL-STD-810G (vibration, shock, temperature), CE, UL |

| Installation | Rack-mounted in VMEbus systems |

Key Features and Advantages

High-Speed Communication Architecture:

The IS215VCMIH2BB’s three IONET Ethernet ports support simultaneous communication with multiple I/O racks or external systems, enabling real-time data exchange for mission-critical applications like gas turbine load control and SCADA integration. The RS-232 port provides backward compatibility with legacy devices, ensuring seamless integration into mixed-technology environments 47.

The IS215VCMIH2BB’s three IONET Ethernet ports support simultaneous communication with multiple I/O racks or external systems, enabling real-time data exchange for mission-critical applications like gas turbine load control and SCADA integration. The RS-232 port provides backward compatibility with legacy devices, ensuring seamless integration into mixed-technology environments 47.

Robust Industrial Design:

Constructed with a rugged metal enclosure and conformal-coated circuitry, the module withstands extreme temperatures, humidity, and mechanical stress. Its compliance with MIL-STD-810G ensures reliable operation in harsh industrial settings, reducing downtime and maintenance costs in environments where failure is not an option.

Constructed with a rugged metal enclosure and conformal-coated circuitry, the module withstands extreme temperatures, humidity, and mechanical stress. Its compliance with MIL-STD-810G ensures reliable operation in harsh industrial settings, reducing downtime and maintenance costs in environments where failure is not an option.

Dual-Port Memory for Real-Time Synchronization:

The dual-port RAM architecture allows the IS215VCMIH2BB to act as a bridge between the system’s CPU and I/O boards, enabling parallel data read/write operations without contention. This feature is critical for maintaining synchronization in high-speed control loops, such as those found in turbine governor systems or robotic automation 4.

The dual-port RAM architecture allows the IS215VCMIH2BB to act as a bridge between the system’s CPU and I/O boards, enabling parallel data read/write operations without contention. This feature is critical for maintaining synchronization in high-speed control loops, such as those found in turbine governor systems or robotic automation 4.

Advanced Diagnostics and Fault Management:

Integrated diagnostics continuously monitor internal power supplies, trigger alarms for voltage anomalies, and provide status feedback via front-panel LEDs (Run/Fail/Status, channel-specific TX/RX/CD indicators). These features simplify troubleshooting and ensure proactive maintenance, minimizing unplanned outages in mission-critical systems 47.

Integrated diagnostics continuously monitor internal power supplies, trigger alarms for voltage anomalies, and provide status feedback via front-panel LEDs (Run/Fail/Status, channel-specific TX/RX/CD indicators). These features simplify troubleshooting and ensure proactive maintenance, minimizing unplanned outages in mission-critical systems 47.

Redundant Configuration Support:

Designed for both simplex and TMR systems, the IS215VCMIH2BB supports multiple communication channels (R, S, T) in TMR setups, ensuring fault tolerance and continuous operation even in the event of a single module failure. This makes it ideal for safety-critical applications in aerospace, defense, and nuclear power sectors 4.

Designed for both simplex and TMR systems, the IS215VCMIH2BB supports multiple communication channels (R, S, T) in TMR setups, ensuring fault tolerance and continuous operation even in the event of a single module failure. This makes it ideal for safety-critical applications in aerospace, defense, and nuclear power sectors 4.

Application Areas

The GE IS215VCMIH2BB is optimized for industries requiring high-reliability communication infrastructure:

- Power Generation:

Integrates gas turbine control systems (e.g., GE Frame 7/9E turbines) with SCADA networks, enabling real-time monitoring of combustion parameters, generator load, and grid synchronization. It also interfaces with distributed I/O racks in combined cycle power plants to manage steam and water workflows. - Oil & Gas:

Manages communication between subsea control modules (SCMs) and topside processing units, ensuring reliable data exchange for wellhead monitoring, pipeline control, and safety shutdown systems. Its rugged design is critical for offshore platforms exposed to saltwater corrosion and extreme weather. - Aerospace & Defense:

Supports avionics systems in military aircraft and unmanned aerial vehicles (UAVs), enabling communication between flight control computers, sensor arrays, and mission payloads. Its TMR compatibility ensures data integrity in high-stakes environments like missile guidance systems. - Heavy Manufacturing:

Connects industrial robots, CNC machines, and quality control systems in automotive and metal fabrication plants, facilitating real-time process adjustments and predictive maintenance. The RS-232 port enables integration with legacy PLCs, extending the lifespan of older automation infrastructure.

Related Products

- GE IS215UCVEH2AE (VMEbus Processor Module):

Paired with the IS215VCMIH2BB, this module provides the computational power for control algorithms, leveraging a 64-bit PowerPC processor and VME64x interface for high-speed data processing in complex systems. - GE VMIVME-7666-111000 (VMEbus Serial Communication Module):

Expands serial connectivity with 8 configurable RS-232/422/485 ports, ideal for integrating legacy sensors or actuators into VMEbus-based control architectures. - GE IS215UCVGM06A (VMEbus Graphics Controller):

Enhances operator visualization by rendering high-resolution HMIs and 3D process models, often used alongside the IS215VCMIH2BB in control rooms for turbine or plant management. - GE IS215UCVEM09A (VMEbus Memory Module):

Provides additional RAM and SSD storage for applications requiring large data logging or program execution, such as turbine performance analysis or historical trend storage. - GE IS215VCMIH2BC (VMEbus Communication Interface Card):

A variant with extended IONET capabilities, supporting higher data throughput for systems with increased I/O rack density or faster control loops.

Installation and Maintenance

Pre-installation Preparations:

- Rack Compatibility: Ensure the VMEbus rack supports 6U modules and provides adequate power (+5V, +12V, +15V, +28V DC) with proper grounding. Verify rack cooling capacity to maintain ambient temperatures within -40°C to +70°C.

- Cable Management: Route IONET and RS-232 cables separately from high-voltage power lines to minimize electromagnetic interference. Use shielded Ethernet cables for IONET connections to ensure signal integrity over long distances.

- Configuration: Use GE’s Mark VI System Configuration Tool to set VMEbus addressing, IONET channel parameters (e.g., baud rate, parity), and enable/disable redundant communication paths. Verify compatibility with existing system firmware versions 47.

Maintenance Suggestions:

- Routine Inspections:

Monthly checks of front-panel LEDs to monitor power status, communication activity, and fault conditions. Use diagnostic software to verify voltage levels and I/O channel performance. - Environmental Management:

Quarterly cleaning of vents and filters to prevent dust accumulation, especially in dusty or oily environments. Ensure proper ventilation to maintain optimal operating temperatures. - Firmware Updates:

Periodically update module firmware to the latest GE-recommended version to address security patches, compatibility improvements, and performance optimizations. - Spare Parts Handling:

Store spare IS215VCMIH2BB modules in anti-static packaging at 10–30°C with <50% humidity. Test spares annually using GE’s Mark VI Test Bench to ensure functionality, particularly for critical applications with limited downtime tolerance.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS215VCMIH2BB, covering hardware defects under normal use. For discontinued models like the IS215VCMIH2BB, our global supply chain network ensures rapid sourcing of replacement parts, minimizing downtime in mission-critical systems. In the event of performance issues, our technical support team offers 24/7 assistance for troubleshooting and configuration guidance, while our repair services (including component-level refurbishment) restore modules to OEM specifications.

For inquiries or urgent spare part requests, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IC660TSA100 Output module

GE IC660TBD024 Gas turbine card

GE IC670CHS101 FIM card

GE IC698PSA100E Network communication

GE IC754CSL12CTD Safety system

GE IC800SSI216RD2-CE Distributed control

GE IC800SSI228RD2-CE Terminal panel

GE IS220PDIAH1A Network communication

GE CK11CE300 Safety system

GE IS200EPSMG1AED Card piece

GE IS200ERDDH1ABA convertor

GE IS200ERIOH1AAA sensor

GE IS200ERIOH1ABB Master control panel

GE IS200EROCH1ABB Switch input module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: