Description

GE IS220PDIOH1B 336A5026ADP6 Product Specification

Product Overview

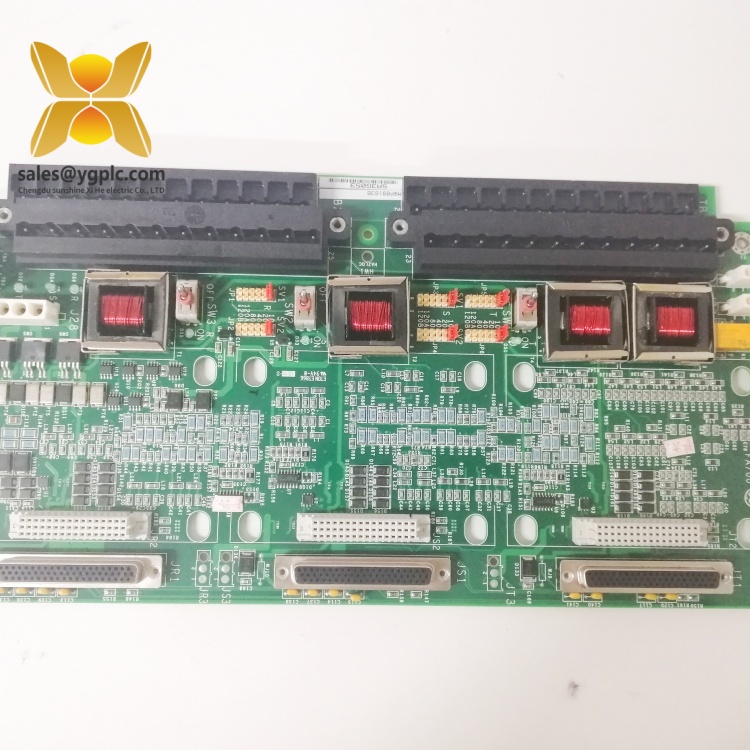

The GE IS220PDIOH1B 336A5026ADP6 is a high-reliability discrete input/output (I/O) pack module designed for GE’s Mark VIe Speedtronic Turbine Control System, delivering precision signal processing in industrial automation. As a key component of GE’s distributed I/O architecture, this module integrates 24 discrete inputs and 12 Type C mechanical relay outputs into a compact 3U VME form factor, making it ideal for mission-critical applications in hazardous and non-hazardous environments .

Featuring dual 100 Mbps Ethernet ports and a local processor, the IS220PDIOH1B ensures sub-millisecond data synchronization with Mark VIe controllers while executing real-time algorithms (e.g., signal filtering, fault detection) independently. Its 1500 Vrms optical isolation between channels and ground safeguards against electrical interference, while hot-swappable operation and front-panel diagnostics (Power, Run, Fault, Ethernet links) enable rapid maintenance . Constructed with a triple-layer conformal coating and IP20-rated enclosure, the module withstands extreme temperatures (-30°C to +65°C), humidity (5–95% non-condensing), and vibration (75 G peak), ensuring longevity in harsh industrial settings .

The IS220PDIOH1B supports simplex, dual, and triple-redundant system configurations, offering flexibility for diverse control requirements. Its 32 VDC contact voltage outputs and compatibility with ATEX Zone 2 and Class I, Division 2 terminal boards (e.g., ISx0YTDBSH2A, ISx0YTDBTH2A) make it suitable for oil refineries, chemical plants, and offshore platforms .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS220PDIOH1B 336A5026ADP6 |

| Manufacturer | General Electric (GE) |

| Product Type | Discrete Input/Output Pack for Industrial Control |

| Series | Mark VIe Speedtronic Turbine Control System |

| Input Channels | 24 dry contact voltage inputs (24 VDC/125 VDC selectable) |

| Output Channels | 12 relay outputs (250 VAC/10A max) |

| Input Isolation | 1500 Vrms optical isolation |

| Output Isolation | 2500 Vrms between channels and ground |

| Power Supply | 24 VDC ±10% (dual redundant inputs optional) |

| Communication Interfaces | 2 × Ethernet (100 Mbps full-duplex) |

| Physical Dimensions | 11.43 cm (W) × 8.89 cm (H) × 5.72 cm (D) |

| Weight | < 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Mounting | VME 64x rack (3U form factor) |

| Certifications | ATEX Zone 2 (Group IIC), Class I, Division 2 (Groups A–D), UL E207865 |

IS220PDIOH1B 336A5026ADP6

Key Features and Advantages

High-Speed Redundant Communication:

The IS220PDIOH1B leverages dual Ethernet ports to enable seamless data exchange with Mark VIe controllers via the IONET protocol, ensuring sub-millisecond synchronization in redundant control architectures. This redundancy minimizes downtime and enhances system resilience in critical operations .

The IS220PDIOH1B leverages dual Ethernet ports to enable seamless data exchange with Mark VIe controllers via the IONET protocol, ensuring sub-millisecond synchronization in redundant control architectures. This redundancy minimizes downtime and enhances system resilience in critical operations .

Flexible I/O Configuration:

With 24 discrete inputs (compatible with switch status, proximity sensors) and 12 relay outputs (for solenoid valves, contactors), the module supports selectable voltage ranges (24 VDC/125 VDC) to interface with diverse field devices. Its DC-37 pin connector directly integrates with terminal boards (e.g., ISx0YTDBSH2A, ISx0YTDBTH2A), simplifying wiring and reducing installation complexity .

With 24 discrete inputs (compatible with switch status, proximity sensors) and 12 relay outputs (for solenoid valves, contactors), the module supports selectable voltage ranges (24 VDC/125 VDC) to interface with diverse field devices. Its DC-37 pin connector directly integrates with terminal boards (e.g., ISx0YTDBSH2A, ISx0YTDBTH2A), simplifying wiring and reducing installation complexity .

Rugged Industrial Design:

The triple-layer conformal coating protects against salt spray, dust, and UV radiation, while the IP20-rated enclosure prevents solid particle ingress. Hot-swappable functionality allows field maintenance without system shutdowns, reducing downtime in mission-critical environments .

The triple-layer conformal coating protects against salt spray, dust, and UV radiation, while the IP20-rated enclosure prevents solid particle ingress. Hot-swappable functionality allows field maintenance without system shutdowns, reducing downtime in mission-critical environments .

Enhanced Safety for Hazardous Locations:

Certified for ATEX Zone 2 and Class I, Division 2 hazardous locations, the IS220PDIOH1B ensures compliance with ANSI/ISA-12.12.01-2015 standards. When paired with compatible terminal boards, it mitigates ignition risks in oil refineries, chemical plants, and offshore platforms .

Certified for ATEX Zone 2 and Class I, Division 2 hazardous locations, the IS220PDIOH1B ensures compliance with ANSI/ISA-12.12.01-2015 standards. When paired with compatible terminal boards, it mitigates ignition risks in oil refineries, chemical plants, and offshore platforms .

Application Areas

-

Power Generation:

- Gas Turbine Control: Monitors overspeed switches and triggers emergency shutdowns via relay outputs to ensure safe operation.

- Steam Turbine Protection: Processes vibration sensor signals and controls cooling systems to prevent mechanical failure .

-

Oil and Gas:

- Wellhead Automation: Interfaces with pressure switches in offshore platforms to initiate safety interlocks and optimize production.

- Pipeline Safety: Monitors flowmeter status and adjusts valve actuators to maintain safe fluid flow rates .

-

Chemical Processing:

- Reactor Control: Monitors temperature/high-level switches and controls solenoid valves for precise batch processes.

- Distillation Column Automation: Adjusts reflux valves based on pressure/temperature inputs to ensure product quality .

-

Industrial Manufacturing:

- Robotic Systems: Processes proximity sensor signals for robotic arm positioning in automotive assembly lines.

- Conveyor Control: Monitors belt alignment switches to prevent material spillage and optimize throughput .

IS220PDIOH1B 336A5026ADP6

Related Products

- GE ISx0YTDBSH2A/ISx0YTDBTH2A: Terminal boards for simplex and triple-modular redundant (TMR) applications, directly compatible with IS220PDIOH1B via DC-37 connectors .

- GE IS220PSCAH1B: Redundant power supply module ensuring stable 24 VDC to the I/O pack.

- GE IS220VCMIH1A: Communication module enabling data exchange with supervisory SCADA systems.

- GE IS220PAICH1A: Analog I/O pack often paired with IS220PDIOH1B for hybrid control systems.

- GE IS200STCIH8A: Terminal board for high-density discrete I/O applications, expanding system scalability.

Installation and Maintenance

Pre-installation Preparation:

- Environmental Checks: Verify ambient temperature (-30°C to +65°C) and humidity (5–95% non-condensing). Use anti-static wrist straps to prevent ESD damage during handling.

- Rack Configuration: Install in a VME 64x rack with anti-vibration brackets, ensuring proper grounding for EMI/EMC compliance. Secure the module with M4 screws to prevent 松动.

- Cabling: Connect Ethernet cables to dual RJ45 ports and terminal boards (e.g., ISx0YTDBSH2A) for field signal integration. Label all connections for traceability.

- Software Setup: Configure I/O channels and communication parameters using GE’s Proficy Machine Edition, ensuring compatibility with Mark VIe controllers .

Maintenance Recommendations:

- Monthly Inspections: Visually check front-panel LEDs and clean dust from ventilation slots. Inspect cable connectors for corrosion or looseness.

- Annual Calibration: Use a certified signal generator to verify input accuracy (±0.5% of full scale) and relay output reliability. Replace degraded terminal blocks or cables.

- Firmware Updates: Periodically update via Proficy to access bug fixes and security patches. Document all changes for traceability.

- Thermal Management: Monitor operating temperatures to detect 异常 hotspots. Replace thermal compound every 2–3 years to maintain optimal heat dissipation .

Product Warranty and Availability

Our company provides a one-year quality warranty for the GE IS220PDIOH1B 336A5026ADP6, covering hardware defects unrelated to misuse or environmental damage. During the warranty period, we offer free replacement for modules exhibiting abnormal performance. For urgent requirements, our global inventory network ensures rapid delivery of scarce parts within 24–48 hours .

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document synthesizes third-party technical resources and industry applications. For detailed installation guides or compliance documentation, refer to GE’s Mark VIe System Manual or contact our technical support team.

GE IS215VPROH1BD | Emergency Turbine Protection Module | IS215VCMIH2CA

GE IS215WEPAH2B | Wind Energy Pitch Axis Controller Board | IS220PDIOH1A

GE IS200WETAH1AGC | Turbine Control Interface Module | IS200WETAH1AGC

GE IS200EXHSG3REC | Excitation Control Module | IS200EROCH1ABB

GE IS220PAICH1A | Power Interface Module | IS220PAOCH1A

GE IS220PAICH1A 336A4940CSP3 | Analog I/O Pack for Hazardous Locations | IS220PPRFH1B

GE IS220PDIAH1BE 336A5026ADP4 | Discrete Input Module | IS220PPRFH1A

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: