Description

HIMA F8652X 984865265 Product Specification

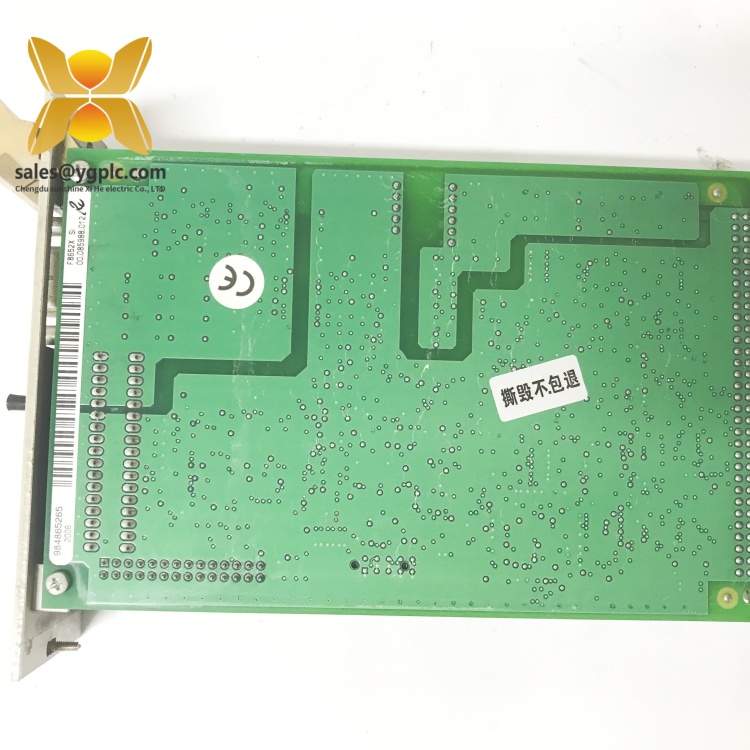

Product Overview :HIMA F8652X 984865265

The HIMA F8652X 984865265 is a high-reliability safety controller module designed for mission-critical industrial safety instrumented systems (SIS). Engineered by HIMA, a global leader in safety automation solutions, this module belongs to the HiPath 4000 series, renowned for its advanced fault-tolerant architecture and compliance with international safety standards such as IEC 61508 and IEC 61511. The HIMA F8652X 984865265 serves as the core processing unit in safety-critical applications, enabling real-time monitoring, logic execution, and emergency shutdown functions to protect personnel, equipment, and the environment across industries like oil & gas, chemical processing, and pharmaceuticals.

At its core, the HIMA F8652X 984865265 features a dual-core processor with built-in hardware redundancy, ensuring continuous operation even in the event of a single component failure. It supports hot-swappable functionality, allowing maintenance or replacement without disrupting the system, a critical advantage in 24/7 industrial environments. The module integrates multiple communication interfaces, including Ethernet and PROFIBUS, for seamless integration with supervisory control systems and field devices. With a compact design (220 mm × 100 mm × 180 mm) and DIN rail mounting, the HIMA F8652X 984865265 offers flexible installation while adhering to strict safety integrity levels (SIL 3).

In automation systems, the HIMA F8652X 984865265 acts as the brain of safety loops, executing safety logic programs with microsecond-level precision. Its modular architecture allows for scalable configurations, from small-scale single-loop systems to large-scale distributed safety networks. By combining high-speed processing with deterministic redundancy, the module minimizes downtime risks and ensures regulatory compliance, making it an essential component for industries where safety failures are not an option.

Technical Specifications :HIMA F8652X 984865265

| Parameter Name | Parameter Value |

|---|---|

| Product Model | HIMA F8652X 984865265 |

| Manufacturer | HIMA |

| Product Type | Safety Controller Module |

| Series | HiPath 4000 |

| Safety Integrity Level | SIL 3 (IEC 61508), TÜV-certified |

| Processor | Dual-core 32-bit RISC, 200 MHz |

| Memory | 512 MB Flash, 256 MB RAM |

| Communication Interfaces | 2x Ethernet (10/100 Mbps), 2x PROFIBUS DP, 1x USB |

| Power Supply | 24 VDC ±15% (dual redundant inputs) |

| Physical Dimensions | 220 mm (W) × 100 mm (H) × 180 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5%–95% non-condensing |

| Installation | DIN rail mountable (EN 50022 standard) |

HIMA F8652X 984865265

Main Features and Advantages :HIMA F8652X 984865265

Hardware Redundancy for Uninterrupted Operation: The HIMA F8652X 984865265 incorporates a dual-core architecture with automatic failover, ensuring that system integrity is maintained even if one processor fails. This redundancy eliminates single points of failure, a critical requirement for safety-critical applications where downtime could lead to catastrophic consequences.

Hot-Swappable Design: The module supports live replacement without powering down the system, reducing maintenance time and minimizing disruptions to ongoing operations. This feature is particularly valuable in industries such as oil refineries, where shutdowns for maintenance are costly and logistically complex.

Advanced Safety Logic Execution: With a processing speed of 200 MHz and dedicated safety logic algorithms, the HIMA F8652X 984865265 executes safety programs with microsecond precision, ensuring rapid response to abnormal conditions. Its support for IEC 61131-3 programming languages (e.g., Ladder Diagram, Structured Text) allows engineers to develop and debug complex safety routines efficiently.

Multi-Protocol Connectivity: The module’s dual Ethernet and PROFIBUS interfaces enable seamless integration with a wide range of devices, from field sensors to supervisory control and data acquisition (SCADA) systems. This flexibility makes it suitable for both standalone safety systems and integrated automation environments.

Rugged Industrial Design: Built to withstand harsh industrial conditions, the HIMA F8652X 984865265 operates reliably in extreme temperatures and high-vibration environments. Its robust construction and rigorous certification (TÜV, CE, UL) ensure long-term durability and compliance with global safety standards.

HIMA F8652X 984865265

Application Areas :HIMA F8652X 984865265

The HIMA F8652X 984865265 is ideally suited for industries where safety is non-negotiable, providing critical control and monitoring in the following scenarios:

-

Oil and Gas Production:

- Used in offshore platforms and onshore refineries to manage emergency shutdown systems (ESD), fire and gas detection systems, and compressor protection. The module’s redundancy and high-speed processing are essential for preventing leaks, explosions, and other hazards in volatile environments.

-

Chemical and Pharmaceutical Manufacturing:

- Controls safety-critical processes such as reactor shutdowns, pressure relief systems, and hazardous material handling. The HIMA F8652X 984865265 ensures compliance with strict regulatory requirements (e.g., FDA, OSHA) by providing traceable, deterministic safety logic.

-

Power Generation:

- Manages safety loops in thermal and nuclear power plants, including turbine trip systems, boiler safety controls, and generator protection. Its ability to interface with legacy systems via PROFIBUS makes it suitable for retrofitting older infrastructure.

-

Process Industries:

- Integrates with distributed control systems (DCS) to monitor and control complex processes, such as distillation columns, conveyor systems, and batch operations. The module’s hot-swappable design minimizes downtime during routine maintenance or component upgrades.

HIMA F8652X 984865265

- Integrates with distributed control systems (DCS) to monitor and control complex processes, such as distillation columns, conveyor systems, and batch operations. The module’s hot-swappable design minimizes downtime during routine maintenance or component upgrades.

Related Products :HIMA F8652X 984865265

- HIMA F8650X 984865263: A compact variant of the HIMA F8652X 984865265 with reduced I/O capacity, ideal for small-scale safety systems or decentralized applications.

- HIMA F8653X 984865266: An upgraded model with enhanced memory and processing speed, designed for large-scale projects requiring high data throughput and complex logic.

- HIMA Z7100 984371001: A PROFIBUS DP interface module that complements the HIMA F8652X 984865265 by expanding connectivity to field devices in distributed safety networks.

- HIMA ELOP II 984350001: A programming and configuration tool for HiPath series modules, enabling engineers to develop, test, and deploy safety logic for the HIMA F8652X 984865265.

- HIMA F3320 984332001: A digital input/output module that works in tandem with the HIMA F8652X 984865265 to interface with sensors and actuators in safety loops.

- HIMA F3230 984323001: An analog input module for precision measurement in processes requiring continuous monitoring of variables like temperature, pressure, or flow rate.

Installation and Maintenance :HIMA F8652X 984865265

Pre-installation Preparation:

Before installing the HIMA F8652X 984865265, ensure the following:

Before installing the HIMA F8652X 984865265, ensure the following:

- Verify that the power supply meets the module’s specifications (24 VDC ±15%) and that redundant power sources are configured if required.

- Clean the installation area to remove dust or debris that could affect heat dissipation or electrical connections.

- Use the appropriate mounting brackets to secure the module to a DIN rail, ensuring proper alignment with adjacent components for optimal airflow.

Maintenance Recommendations:

- Regularly inspect the module’s LED indicators to monitor status (e.g., power, communication, fault signals). Unusual blinking or solid red lights may indicate a need for troubleshooting.

- Perform routine firmware updates using HIMA’s ELOP II software to access the latest security patches and functional enhancements.

- In high-dust environments, clean the module’s ventilation slots with compressed air to prevent overheating. Avoid using liquid cleaners that could damage internal components.

- For redundant systems, test failover functionality periodically to ensure seamless switching between active and standby processors.

HIMA F8652X 984865265

Product Warranty :HIMA F8652X 984865265

Our company provides a one-year quality warranty for the HIMA F8652X 984865265, covering hardware defects and non-human-induced failures. During the warranty period, we will replace any defective module promptly to minimize downtime. For discontinued models or urgent needs, our global supply chain network ensures fast access to rare or obsolete spare parts, supporting the longevity of your industrial safety systems. We stand behind the reliability of our products and are committed to delivering exceptional service to ensure your operational continuity.

Note: This product description is based on comprehensive industry research and HIMA’s technical documentation. For detailed operational guidelines, refer to the official module manual or contact our technical support team.

For inquiries, contact us via WhatsApp: +86 18859254943 or email: sales@ygplc.com

ABB 500MBA02 1MRB150003R000B encoder

ABB 500MBA02 1MRB150003R0003 1MRB200053M regulator

ABB 500AIM02 1MRB150022 R0002Y 1HDF 930412 X010 I/O board

ABB 500BIM01 1MRB150024R0002 Counting plate

GE IS220PDIAH1A driver

GE CK11CE300 servo

FOXBORO FBM202 P0926EQ Network communication

CONVERTEAM P110-6052 Safety system

FOXBORO P0926GV FBM231 Distributed control

AMAT 0010-23716 Terminal panel

ABB 500MBA02 1MRB150003R0003 1MRB200053M regulator

ABB 500AIM02 1MRB150022 R0002Y 1HDF 930412 X010 I/O board

ABB 500BIM01 1MRB150024R0002 Counting plate

GE IS220PDIAH1A driver

GE CK11CE300 servo

FOXBORO FBM202 P0926EQ Network communication

CONVERTEAM P110-6052 Safety system

FOXBORO P0926GV FBM231 Distributed control

AMAT 0010-23716 Terminal panel

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: