Description

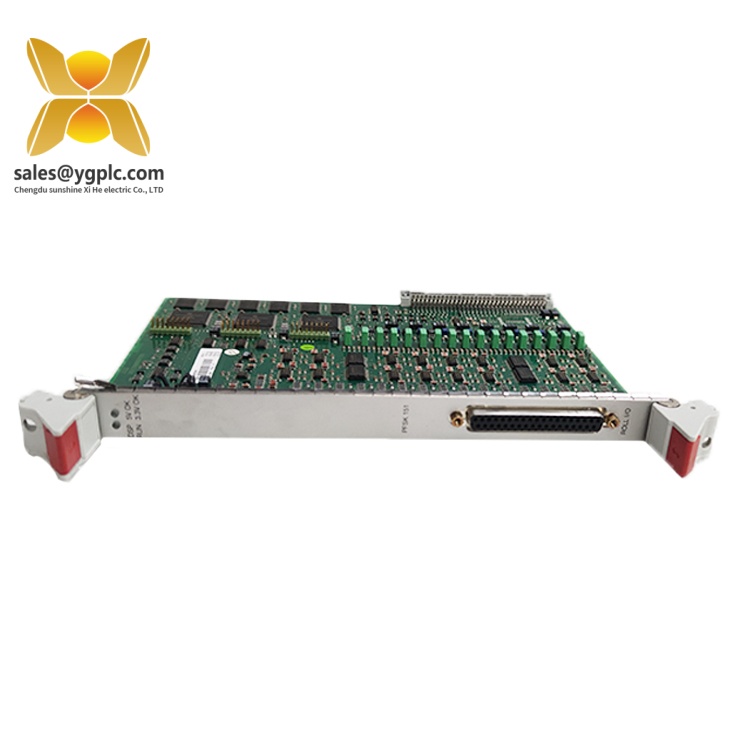

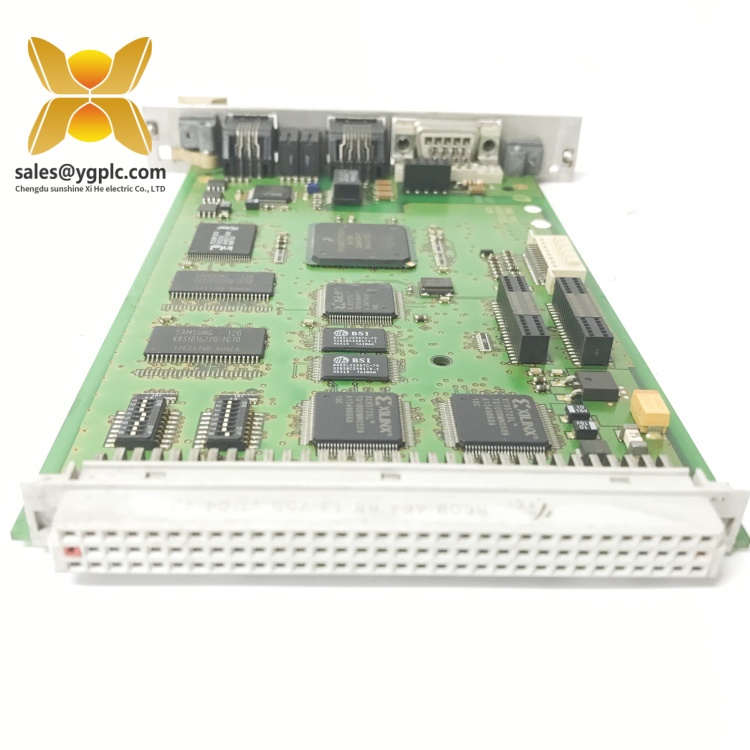

HIMA F8627 984862702 Safety Control Module

Product Overview:HIMA F8627 984862702

The HIMA F8627 984862702 is a high-reliability Safety Control Module designed for mission-critical industrial applications requiring strict compliance with functional safety standards. As a core component of HIMA’s ELOP II safety instrumented system (SIS), this module provides advanced logic processing and safety-related control for processes in industries such as oil & gas, chemical manufacturing, and power generation. The F8627 984862702 is engineered to execute safety-critical functions, including emergency shutdown (ESD), fire and gas detection, and machinery protection, ensuring minimal risk of hazardous incidents and operational downtime.

Featuring a dual-core architecture with hardware redundancy, the HIMA F8627 984862702 delivers fault-tolerant performance, continuously monitoring its own integrity while processing input signals from field devices (e.g., sensors, switches) and driving output actuators. The module supports configurable safety logic via HIMA’s PLANAR engineering software, allowing users to tailor control strategies to specific application requirements. With certifications with IEC 61508 (SIL 3) and IEC 61511, the F8627 984862702 is ideal for safety loops requiring the highest levels of dependability.

In automation ecosystems, the HIMA F8627 984862702 serves as the central processing unit in safety systems, bridging field-level instrumentation with higher-level control systems. Its compact design (130 mm × 100 mm × 150 mm) and modular construction enable seamless integration into existing control panels, while its rugged build (IP20 protection) ensures stable operation in harsh environments with temperatures ranging from -25°C to +60°C. By combining real-time data processing with fail-safe mechanisms, this module minimizes the risk of unplanned outages and protects personnel, equipment, and the environment.

Technical Specifications:HIMA F8627 984862702

| Parameter Name | Parameter Value |

|---|---|

| Product Model | F8627 984862702 |

| Manufacturer | HIMA |

| Product Type | Safety Control Module |

| Core Architecture | Dual-core redundant |

| Input Voltage | 24 V DC ±15% |

| Communication | PROFIBUS DP, Ethernet (via optional modules) |

| Physical Dimensions | 130 mm (H) × 100 mm (W) × 150 mm (D) |

| Weight | 1.2 kg |

| Safety Integrity Level | SIL 3 (IEC 61508), TÜV-certified |

| Operating Temperature | -25°C to +60°C |

| Mounting | DIN rail (35 mm) |

| Certifications | CE, ATEX, IECEx, FM |

HIMA F8627 984862702

Key Features and Advantages:HIMA F8627 984862702

Dual-Core Redundancy: The F8627 984862702 employs a dual-core design with independent power supplies and data paths, ensuring continuous operation even if one core detects a fault. This redundancy eliminates single points of failure, critical for safety systems where downtime could lead to catastrophic consequences.

Advanced Safety Logic: Using HIMA’s PLANAR software, users can program complex safety logic sequences, including time delays, interlocks, and voting schemes (e.g., 2oo3 architecture). The module supports up to 2,000 logic elements, accommodating both simple and highly complex safety applications.

Real-Time Diagnostics: Built-in self-diagnostics monitor component health, communication integrity, and power supply status, with diagnostic coverage exceeding 99%. LED indicators provide instant feedback on module status, reducing troubleshooting time during critical events.

Modular Scalability: The HIMA F8627 984862702 integrates seamlessly with HIMA’s ELOP II I/O modules (e.g., analog input, relay output), allowing scalable system design from small-scale applications to large industrial plants. Its support for PROFIBUS DP and Ethernet enables integration with DCS or SCADA systems for centralized monitoring.

Rugged Industrial Design: Encased in a shock-resistant enclosure with conformal coating, the module withstands vibration, moisture, and electromagnetic interference (EMI), making it suitable for harsh industrial environments, including offshore platforms and chemical plants.

Regulatory Compliance: With SIL 3 certification and compliance with major industry standards (e.g., API 556, ANSI/ISA 84.00.01), the F8627 984862702 simplifies regulatory approval processes, reducing project lead times and ensuring compliance with global safety regulations.

HIMA F8627 984862702

Application Areas:HIMA F8627 984862702

The HIMA F8627 984862702 is indispensable in industries where safety is non-negotiable:

- Oil & Gas: Deployed in upstream production facilities, refineries, and pipelines to manage ESD systems, monitor gas leaks, and protect high-pressure equipment. 典型应用包括 offshore platform safety shutdown systems and compressor anti-surge control.

- Chemical & Petrochemical: Controls safety interlocks in reactor systems, manages fire and gas detection networks, and ensures safe operation of distillation units. The module’s ability to handle complex logic sequences is critical for preventing chemical spills or explosions.

- Power Generation: Manages turbine trip systems, boiler safety controls, and emergency diesel generator startups in thermal and nuclear power plants, ensuring grid stability and personnel safety.

- Pharmaceuticals & Food Processing: Ensures compliance with hygiene standards by controlling sterilization processes, monitoring critical utility systems (e.g., HVAC), and preventing contamination risks.

Specific applications include:

- Safety Instrumented Systems (SIS): As the logic solver in SIS architectures, the F8627 984862702 processes inputs from sensors (e.g., pressure switches, flame detectors) and triggers actions like valve closure or equipment shutdown.

- Machinery Protection: Monitors vibration, temperature, and shaft position in rotating machinery, initiating protective actions to prevent damage from mechanical failures.

- Process Automation: Integrates with control valves and variable speed drives to maintain process parameters within safe limits, supporting both safety and operational efficiency.

HIMA F8627 984862702

Related Products:HIMA F8627 984862702

- HIMA F8650 984865002: A high-performance safety controller with expanded memory and processing power, suitable for large-scale applications requiring advanced logic capabilities.

- HIMA F8628 984862802: A compact single-core variant for less critical safety loops, offering cost-effective solutions for small-to-medium systems.

- HIMA F8333 984833302: Analog input module for connecting temperature, pressure, or level sensors to the ELOP II system, complementing the F8627 984862702 in mixed-signal applications.

- HIMA F8450 984845002: Relay output module with fail-safe contacts for driving actuators (e.g., solenoid valves, motor starters), ensuring reliable physical isolation in safety loops.

- HIMA F8711 984871102: Ethernet communication module enabling remote access and diagnostics for the F8627 984862702, supporting protocols like Modbus TCP and OPC UA.

- HIMA F8216 984821602: Digital input module with 16 isolated channels for connecting discrete sensors (e.g., limit switches, pushbuttons), expanding the system’s field device connectivity.

- HIMA F8901 984890102: Power supply module with redundant inputs, ensuring stable power delivery to the F8627 984862702 and other ELOP II components.

- HIMA F8607 984860702: Expansion module for increasing the number of I/O channels in distributed control systems, enhancing the scalability of safety installations.

Installation and Maintenance:HIMA F8627 984862702

Installation Preparation:

Before installing the HIMA F8627 984862702, ensure the DIN rail is securely grounded and located in a ventilated control panel. Verify the power supply (24 V DC) meets voltage and ripple specifications, and use shielded cables for all signal connections to minimize EMI. Mount the module vertically, leaving at least 20 mm of space between adjacent components for heat dissipation. Configure the module’s address and communication parameters using HIMA’s ELOP II Configurator software before powering up the system.

Before installing the HIMA F8627 984862702, ensure the DIN rail is securely grounded and located in a ventilated control panel. Verify the power supply (24 V DC) meets voltage and ripple specifications, and use shielded cables for all signal connections to minimize EMI. Mount the module vertically, leaving at least 20 mm of space between adjacent components for heat dissipation. Configure the module’s address and communication parameters using HIMA’s ELOP II Configurator software before powering up the system.

Maintenance Recommendations:

- Routine Inspections: Perform quarterly visual checks for loose connections, damaged components, or signs of overheating. Use a dry cloth to clean dust from the module’s vents, ensuring proper airflow.

- Functional Testing: Conduct annual loop tests to verify the F8627 984862702 responds correctly to simulated fault conditions. Document test results to comply with safety audit requirements.

- Firmware Updates: Periodically update the module’s firmware using HIMA’s official tools to access new features and security patches. Ensure backups of existing logic programs before initiating updates.

- Spare Parts Management: Store spare F8627 984862702 modules in anti-static packaging at room temperature (20°C ± 5°C) and low humidity (<60% RH) to preserve component longevity.

HIMA F8627 984862702

Product Warranty:HIMA F8627 984862702

Our company provides a 12-month quality warranty for the HIMA F8627 984862702, covering hardware defects under normal use. In the event of performance issues or functional failures, we offer prompt replacement services. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of hard-to-find components, supporting uninterrupted operation of industrial systems. Our technical support team is available 24/7 to assist with installation, programming, and troubleshooting, ensuring the F8627 984862702 integrates seamlessly into your safety infrastructure.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

ABB G2000A5.7ST Power source

A-B 1336-QOUT-SP23A base

ABB 3BHE017628R0002 PPD115A02 SG579989013 exchange

Siemens 6DD2920-0AL0 DI module

Siemens 6DD2920-0AM0 AI card

Siemens 6DD2920-0BB0 Pulse encoder

HONEYWELL 51401497-100 FW25-92 Module connector

Bently 3500/44M 140734-03 03S Servo module

HONEYWELL EG1033AA EG1033AA01 261A1812P002 Control cabinet node unit

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: