Description

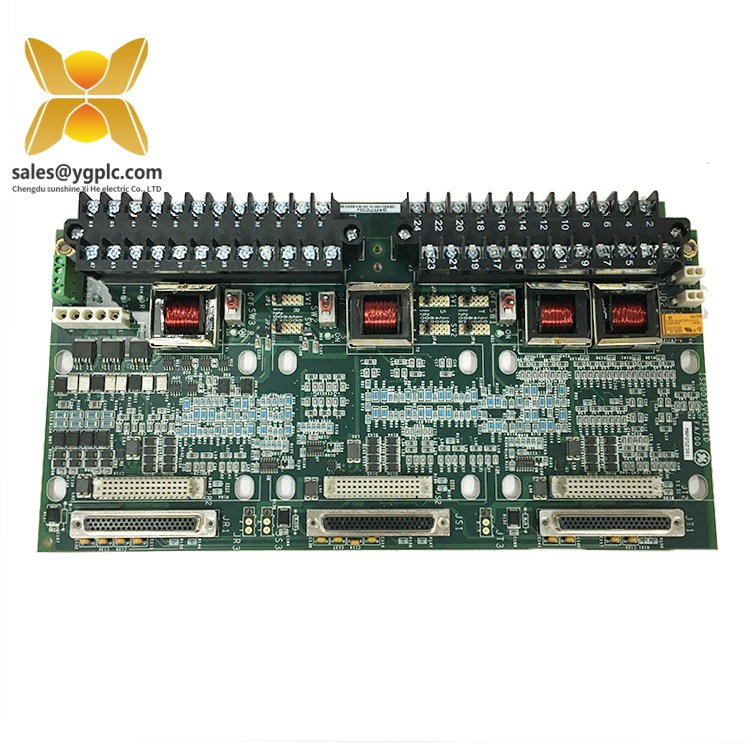

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS215ACLEH1BB |

| Manufacturer | General Electric (GE) |

| Product Type | Application Control Layer (ACLE) Module |

| Communication Protocols | Modbus RTU, TCP/IP, IS Bus, Ethernet Global Data |

| Input Voltage | 125 VDC ±10% |

| Output Voltage | 24 VDC |

| Processor | 266 MHz microprocessor |

| Memory | 8 MB DRAM, 4 MB Flash |

| Physical Dimensions | 23.495 cm (H) × 10.795 cm (W) |

| Weight | 1 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Mounting | VME rack-compatible, metal faceplate with DIN rail support |

| Certifications | CE, UL (pending GE documentation) |

Main Features and Advantages

Application Areas

-

Power Generation:

- Controls steam turbine governors in thermal power plants, maintaining grid stability and optimizing energy efficiency.

- Manages gas turbine start-up/shutdown sequences in combined cycle power plants, integrating with generator excitation systems for seamless synchronization.

-

Oil and Gas:

- Regulates compressor motors in refineries and pipeline pumping stations, ensuring optimal flow rates and preventing thermal overload.

- Integrates with emergency shutdown (ESD) systems in offshore platforms, enforcing safety protocols during critical events.

-

Industrial Manufacturing:

- Drives high-speed conveyor systems and robotic arms in automotive and pharmaceutical plants, enabling precise motion control and quality assurance.

- Supports SCADA integration in large-scale manufacturing facilities, providing centralized monitoring of distributed turbine systems.

-

Water/Wastewater Treatment:

- Manages pump motors in water treatment facilities, maintaining consistent flow for filtration and chemical dosing.

- Controls aeration systems in wastewater plants, optimizing biological processes for efficient effluent treatment.

Related Products

- GE IS210MACCH2AEG: A motor control and communication module for GE’s Mark VIe system, often paired with the GE IS215ACLEH1BB for integrated turbine control.

- GE IS210PPROH1B: A power supply module that provides stable 24 VDC for the GE IS215ACLEH1BB and other Mark VI components.

- GE IS200MCCA: A communication adapter module that expands network connectivity for the GE IS215ACLEH1BB in large-scale setups.

- GE IS210TPROS1B: A temperature monitoring module that pairs with the GE IS215ACLEH1BB to provide comprehensive thermal management data.

- GE IS210VCMCH1A: A voltage control module that works in tandem with the GE IS215ACLEH1BB for precise power regulation in generator applications.

- GE IS215ACLEH1BC: An upgraded variant of the GE IS215ACLEH1BB, featuring enhanced memory and processing capabilities for advanced control tasks.

Installation and Maintenance

Before installing the GE IS215ACLEH1BB, ensure the following:

- Verify the control cabinet is properly grounded to prevent electrostatic discharge (ESD) and voltage fluctuations. Use an ESD grounding mat and wrist strap during handling.

- Confirm the ambient temperature (-30°C to +65°C) and humidity (5–95% non-condensing) fall within the module’s operational range.

- Inspect the VME rack for compatibility with the module’s metal faceplate and mounting brackets. Secure the module with anti-vibration fasteners to minimize mechanical stress.

- Use GE’s Proficy software to configure communication parameters (IP address, baud rate) and load control applications tailored to the turbine system.

- Routine Inspections: Monthly visual checks of front-panel LEDs and ventilation slots. Clean dust from the heat sink using compressed air to maintain optimal thermal performance.

- Thermal Management: Replace thermal compound on the microprocessor every 2–3 years or after any repair involving heat sink removal to ensure efficient heat dissipation.

- Firmware Updates: Periodically update the module’s firmware via Proficy software to access bug fixes, security patches, and compatibility enhancements.

- Functional Testing: Quarterly verification of control logic and communication protocols using a calibrated signal generator and diagnostic tools. Document test results for compliance and audit purposes.

Product Warranty

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

GE IS200TREGH1BDB | Turbine Control Module | IS200TBCIH2CAA

GE IS200TREGH1BEC | Turbine Regulation Control Module | IS200TSVCH1A

GE IS200TSVCH1AJE | Turbine Speed and Vibration Control Module | IS200TREGH1BEC

GE IS200TRPAH2AHE | Mark VIe Turbine Control Relay Module | IS200TDBTH6ABC

GE IS200VAICH1DAB | Exciter Control Module for Mark VIe Series | IS200WREAS1ADB

GE IS200VCRCH1B | Control Relay Module | IS200VPROH1BEF

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200TBCIH1BBC | Contact Terminal Board, Mark VIe Series | IS200TDBSH2ACC

GE IS200TDBSH2ACC | Mark VIe Terminal Base Module |

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: