Description

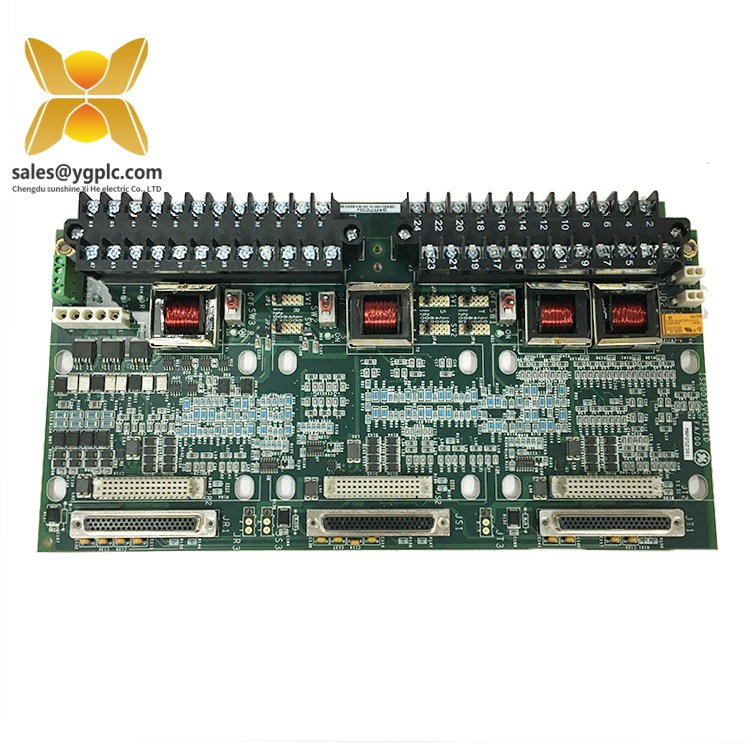

Product Overview :GE IS210WSVOH1AE

Technical Specifications :GE IS210WSVOH1AE

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS210WSVOH1AE |

| Manufacturer | General Electric (GE) |

| Product Type | Power Control and Thermal Management PCB |

| Weight | 1 kg |

| Operating Temperature | -25°C to +70°C (estimated based on GE industrial standards) |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL (pending GE documentation) |

| Compatibility | GE 336A4940FFP80 Rev 4 Turbine Control System |

| Cooling Mechanism | Integrated heat sink with forced-air compatibility |

| Component Type | High-power thyristor driver and voltage regulation circuitry |

Main Features and Advantages :GE IS210WSVOH1AE

Application Areas :GE IS210WSVOH1AE

-

Renewable Energy:

- Manages power conversion in combined cycle gas turbine (CCGT) plants, integrating with generators to optimize energy output from natural gas and steam cycles.

- Supports voltage regulation in offshore wind farm gas turbine backup systems, ensuring stable power supply during grid outages.

-

Oil and Gas:

- Controls compressor motors in refinery gas recovery systems, maintaining optimal flow rates and preventing thermal overload in high-temperature environments.

- Integrates with emergency shutdown (ESD) systems in LNG processing facilities, ensuring safe and rapid response to critical events.

-

Industrial Power Generation:

- Regulates steam turbine governors in manufacturing plants, providing consistent power for heavy machinery and process heating.

- Manages generator excitation systems in cogeneration plants, balancing power output between electricity and thermal energy production.

-

Water/Wastewater Treatment:

- Controls high-power pumps in wastewater treatment facilities, ensuring reliable operation of aeration systems and sludge handling processes.

- Integrates with SCADA systems for remote monitoring of distributed pump stations in large-scale water distribution networks.

Related Products :GE IS210WSVOH1AE

- GE IS210MACCH2AEG: A motor control and communication module compatible with GE’s Mark VIe system, often used alongside the GE IS210WSVOH1AE in turbine control loops.

- GE IS210PPROH1B: A power supply module that provides stable 24 VDC for the GE IS210WSVOH1AE and other components in the 336A4940FFP80 Rev 4 system.

- GE IS210TPROS1B: A temperature monitoring module that pairs with the GE IS210WSVOH1AE to provide comprehensive thermal management data for turbine components.

- GE IS200MCCA: A communication adapter module that expands network connectivity for the GE IS210WSVOH1AE in large-scale automation setups.

- GE IS210VCMCH1A: A voltage control module that works in tandem with the GE IS210WSVOH1AE to optimize power regulation in generator applications.

Installation and Maintenance :GE IS210WSVOH1AE

Before installing the GE IS210WSVOH1AE, ensure the following:

- Verify the control cabinet is properly grounded to prevent electrostatic discharge (ESD) damage. Use an ESD grounding mat and wrist strap during handling.

- Confirm the ambient temperature and humidity fall within the module’s operational range (-25°C to +70°C, 5–95% non-condensing).

- Check the mounting bracket compatibility with the GE 336A4940FFP80 Rev 4 control rack, ensuring secure fastening to minimize vibration-induced displacement.

- Inspect the module for physical damage (e.g., bent pins, cracked heat sink) and clean any dust or debris from connectors and ventilation slots.

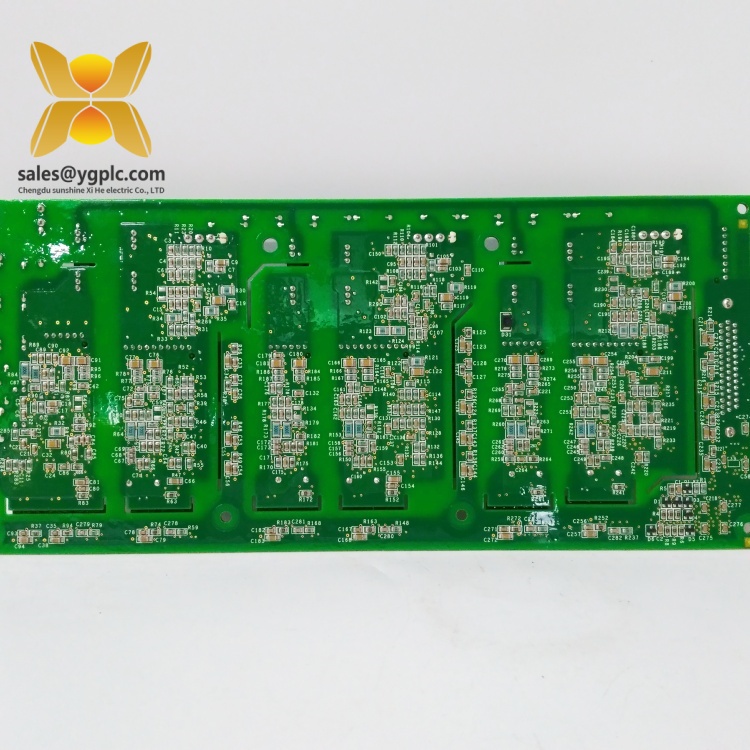

- Routine Inspections: Monthly visual checks of the heat sink for dust accumulation and thermal compound integrity. Use compressed air to clean vents and a non-conductive brush for delicate components.

- Thermal Performance Testing: Quarterly verification of temperature readings using a non-contact infrared thermometer, ensuring no hotspots exceed GE’s specified thresholds.

- Firmware Updates: Periodically update the module’s firmware via GE’s Proficy software (if applicable) to access bug fixes and compatibility enhancements for newer system versions.

- Component Replacement: Replace the thermal compound every 2–3 years or after any repair involving heat sink removal to maintain optimal thermal conductivity.

Product Warranty :GE IS210WSVOH1AE

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document synthesizes available technical data and industry insights. For precise specifications and installation guidelines, refer to GE’s official 336A4940FFP80 Rev 4 Turbine Control System Manual or contact our technical support team for personalized assistance.

GE IC697PWR724 Digital input module

GE IC697PWR748 Digital 24VDC output module

GE IC697VDD100 | DC Power Supply Module | IC697PWR748

GE IC670PBI001 Fault-tolerant board

GE IS220PDIAH1A Network communication

GE CK11CE300 Safety system

GE IC695CPE400-ABAB Distributed control

GE IS420UCSBH3A Terminal panel

GE IC660TBD024 Gas turbine card

GE IC670CHS101 FIM card

GE IC670CPU350 Communication input interface component

GE IC660BBD023 Connection base plate

GE IS200TTURH1CCC S1DF00Z Eddy current sensor

GE IS200TRLYH1BGF monitor

GE CK11CE300 Safety system

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: