Description

GE IS210BPPCH1AD Product Specification

Product Overview

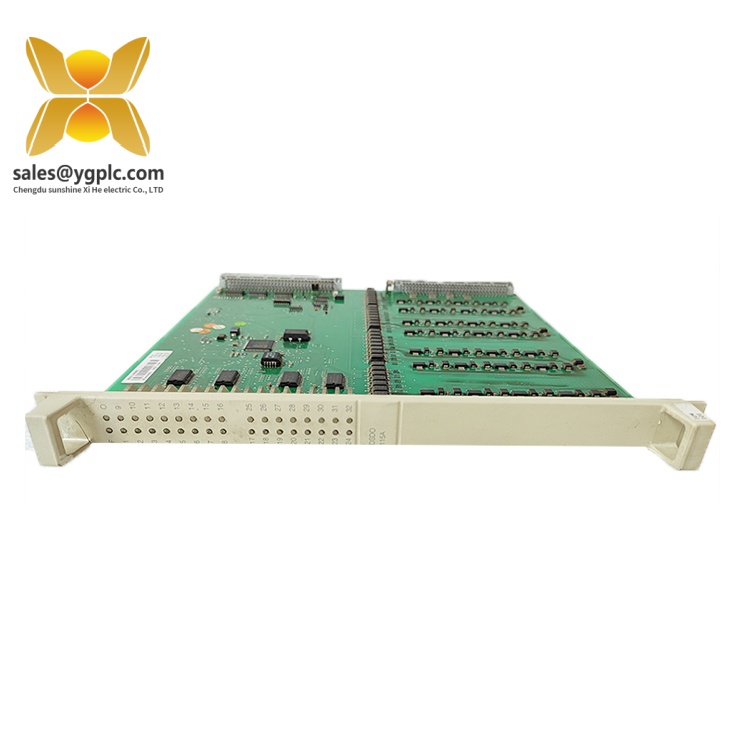

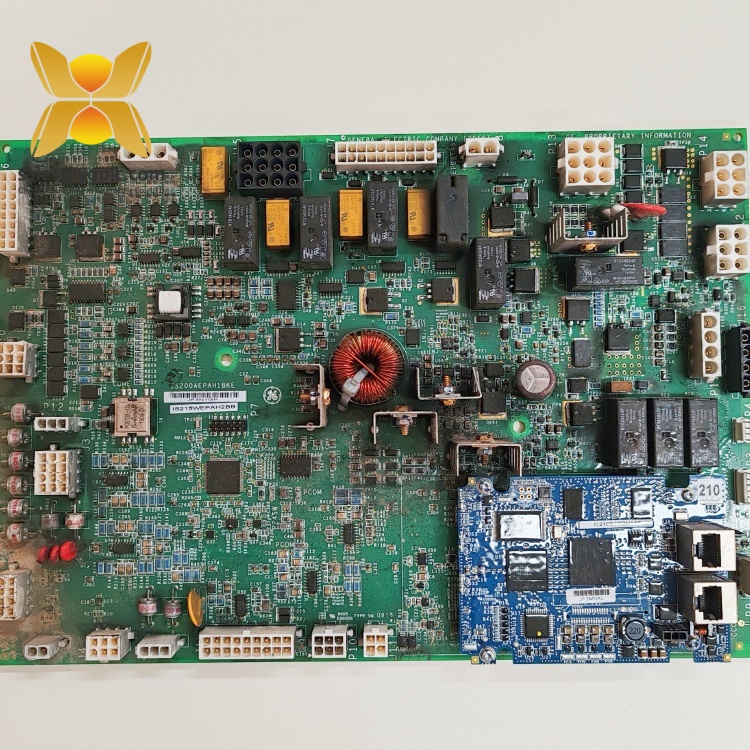

The GE IS210BPPCH1AD is a high-performance I/O Pack Processor Board designed for GE’s Mark VIe Turbine Control System, serving as the backbone of industrial automation in mission-critical power generation and process control environments. Engineered to deliver real-time data processing and communication capabilities, this module is a cornerstone of the Mark VIe series, enabling seamless integration of sensors, actuators, and higher-level control systems. The GE IS210BPPCH1AD is specifically optimized for gas, steam, and wind turbine applications, where precision, reliability, and ruggedness are paramount.

Featuring a dual Ethernet interface and RS-485 connectivity, the GE IS210BPPCH1AD processes signals from proximity probes, temperature sensors, and actuators, converting raw data into actionable insights for machinery health management. Its surface-mount technology (SMT) and conformal-coated circuitry ensure durability in harsh environments, including extreme temperatures (-25°C to +60°C), high humidity, and electromagnetic interference (EMI). The board’s compact form factor (200 mm × 150 mm × 30 mm) and lightweight design (0.8 kg) facilitate easy installation in 19″ control racks, while factory-drilled mounting holes and conductive grounding rings simplify integration into existing systems.

As a critical component of the Mark VIe ecosystem, the GE IS210BPPCH1AD supports protocols like Ethernet/IP and Modbus RTU, enabling bidirectional communication with PLCs, HMIs, and SCADA systems. Its 32-bit microprocessor and 16 MB of flash memory ensure rapid data throughput and program storage, while built-in diagnostic LEDs provide real-time status updates. By delivering accurate, low-latency data acquisition and control, the GE IS210BPPCH1AD minimizes downtime, enhances operational safety, and optimizes energy efficiency in industrial installations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS210BPPCH1AD |

| Manufacturer | GE FANUC |

| Product Type | I/O Pack Processor Board |

| Communication Protocols | Ethernet/IP, Modbus RTU, TCP/IP |

| Input/Output | 2 × Ethernet ports, 1 × RS-485 |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 200 mm (W) × 150 mm (H) × 30 mm (D) |

| Weight | 0.8 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 16132 |

| Compatibility | GE Mark VIe Turbine Control System |

Main Features and Advantages

High-Speed Data Processing: The GE IS210BPPCH1AD leverages a 32-bit microprocessor and dedicated firmware to handle real-time input/output operations, ensuring rapid response to turbine speed fluctuations, vibration anomalies, or temperature deviations. This capability is critical for maintaining precise control in dynamic industrial processes.

Multi-Protocol Connectivity: With support for Ethernet/IP and Modbus RTU, the module integrates seamlessly with both legacy and modern control systems. This versatility eliminates the need for separate gateways, reducing complexity and costs in large-scale automation architectures.

Rugged Industrial Design: Built with SMT technology and a conformal-coated PCB, the GE IS210BPPCH1AD resists dust, moisture, and chemical corrosion. Its IP23-rated enclosure and anti-vibration mounting brackets make it suitable for offshore platforms, refineries, and other harsh environments.

Hot-Swap Capability: The board’s hot-swappable design allows replacement without powering down the entire system, minimizing downtime during maintenance. This feature is particularly valuable in 24/7 operational settings where continuous uptime is non-negotiable.

Diagnostic and Redundancy Features: LED indicators for power, communication, and fault status enable quick troubleshooting, while dual Ethernet ports support redundant network configurations. The module also logs diagnostic data for post-fault analysis, aiding predictive maintenance strategies.

Application Areas

The GE IS210BPPCH1AD is deployed across industries requiring advanced turbine control and data integration:

-

Power Generation:

- Monitors steam and gas turbines in thermal power plants, ensuring optimal energy conversion and grid stability.

- Supports wind turbine control systems by processing rotational speed, blade pitch, and generator load data, enabling efficient power output and grid synchronization.

-

Oil and Gas:

- Manages compressor and pump operations in refineries and pipelines, detecting early signs of cavitation or motor overload.

- Integrates with offshore platform control systems to monitor turbine-driven gas compressors, ensuring safe and efficient hydrocarbon processing.

-

Manufacturing:

- Controls high-speed machinery in automotive and pharmaceutical plants, where precise rotational and torque monitoring is critical for quality assurance.

- Enables condition-based maintenance of large industrial fans and blowers by analyzing vibration and temperature data in real time.

-

Water and Wastewater Treatment:

- Optimizes pump performance in water treatment facilities by translating sensor data into actionable control signals for variable frequency drives (VFDs).

- Ensures reliable operation of wastewater aeration systems through robust data acquisition and communication.

Related Products

- GE IS210BPPCH1A: A predecessor model with similar functionality, often used as a cost-effective alternative in smaller systems.

- GE IS220PAICH1A: An analog I/O pack designed for basic sensor integration, complementing the GE IS210BPPCH1AD in multi-channel monitoring setups.

- GE IS220PPDH1A: A power supply module for the Mark VIe series, ensuring stable 24 VDC delivery to the GE IS210BPPCH1AD and other system components.

- GE IS220PVIBH1A: A vibration monitoring module that pairs with the GE IS210BPPCH1AD to provide comprehensive machinery health analysis.

- GE IS220PTURH1A: A thermocouple I/O pack for temperature-sensitive applications, expanding the system’s environmental monitoring capabilities.

- GE IS220PSCAH1A: A serial communication module for integrating legacy devices, enhancing the GE IS210BPPCH1AD’s compatibility with older control systems.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS210BPPCH1AD, ensure the following:

Before installing the GE IS210BPPCH1AD, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control rack is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability and continuity.

- Clean the installation area to remove dust and debris, and ensure adequate ventilation for cooling. The module should be mounted in a 19″ rack with at least 50 mm of clearance on all sides.

- Use GE’s ProTool software to configure IP addresses, subnet masks, and communication protocols based on the network architecture. Test connectivity with neighboring modules to ensure seamless integration.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs and connections. Clean ventilation slots with a soft brush to prevent dust buildup that could impair heat dissipation.

- Calibration and Testing: Annually verify input/output accuracy using GE-certified calibration tools. Simulate sensor signals to ensure proper response and alarm triggering.

- Firmware Updates: Periodically update the module’s firmware via GE’s software to access new features, security patches, and compatibility improvements.

- Redundancy Checks: Biannually test dual Ethernet ports and communication protocols to ensure failover capability during network interruptions. Document test results for compliance and audit purposes.

Product Warranty

Our company provides a one-year quality warranty for the GE IS210BPPCH1AD, covering hardware defects and malfunctions not caused by misuse or environmental damage. During the warranty period, we will promptly replace any module exhibiting abnormal signal processing, communication failures, or component defects. For discontinued models like the GE IS210BPPCH1AD, our extensive global inventory of industrial automation parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including repair services and calibration assistance, to help maintain your system’s reliability and operational efficiency throughout its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from GE’s official specifications and industry applications. For detailed installation and troubleshooting guidelines, refer to the GE IS210BPPCH1AD user manual or contact our technical support team.

GE IS200TRLYH1BHH Regulator

GE IS200EPMCH1 I/O board

GE IS215UCCCM04A Counting plate

GE IS215UCCCM04AB Optical fiber interface board

GE IC660TBD024 Gas turbine card

GE IC670CHS101 FIM card

GE IC698PSA100E Network communication

GE IC754CSL12CTD Safety system

GE IC800SSI216RD2-CE Distributed control

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: