Description

GE IS200VTURH2BAC Product Specification

Product Overview

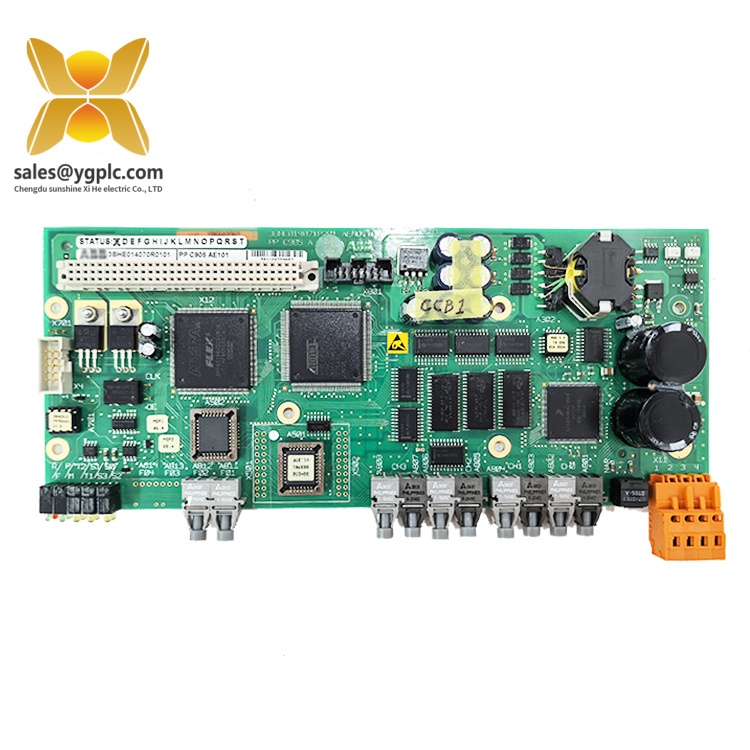

The GE IS200VTURH2BAC is a high-reliability turbine control module designed for GE’s Mark VIe Industrial Turbine Control System. Engineered to deliver precise speed and load control for steam and gas turbines, this module serves as a critical component in industrial automation systems, enabling seamless operation of power generation and process machinery. As part of GE’s Mark VIe platform, the GE IS200VTURH2BAC integrates advanced control algorithms with rugged hardware, making it ideal for industries such as power generation, oil and gas, and manufacturing that require reliable turbine management.

The GE IS200VTURH2BAC features the Speedtronic™ control technology, supporting up to four independent control loops for precise regulation of turbine speed, exhaust temperature, and load sharing. It processes analog and digital inputs from sensors and actuators, converting them into control signals for valve positioning and fuel metering. The module’s dual-processor architecture ensures redundancy and fault tolerance, while its 24 VDC power supply and wide operating temperature range (-40°C to +70°C) make it suitable for harsh industrial environments. With an IP23-rated enclosure and conformal-coated PCBs, the GE IS200VTURH2BAC resists dust, moisture, and electromagnetic interference (EMI), ensuring stable performance in critical applications.

In automation systems, the GE IS200VTURH2BAC acts as a central control hub, interfacing with PLCs, HMIs, and supervisory systems via protocols like Modbus and Ethernet/IP. Its built-in diagnostic tools monitor system health and alert operators to anomalies, minimizing downtime. By combining precise control capabilities with robust industrial design, the module empowers engineers to optimize turbine efficiency, reduce maintenance costs, and ensure compliance with safety standards.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200VTURH2BAC |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Control Module |

| Control Loops | 4 independent loops (speed, load, temperature) |

| Input Voltage | 24 VDC ±10% |

| Communication Protocols | Modbus RTU, Ethernet/IP, TCP/IP |

| Physical Dimensions | 203 mm (W) × 152 mm (H) × 102 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Enclosure Protection | IP23 |

| Redundancy | Dual-processor architecture |

| Certifications | CE, UL |

Main Features and Advantages

Precision Turbine Control: The GE IS200VTURH2BAC delivers sub-0.1% speed regulation accuracy, ensuring stable turbine operation even under fluctuating load conditions. Its four independent control loops enable simultaneous management of speed, exhaust temperature, and load sharing, critical for optimizing energy production in power plants.

Dual-Processor Redundancy: The module’s redundant processor design ensures continuous operation during single-point failures, with automatic failover to maintain control without disruption. This feature is vital for 24/7 industrial applications where downtime is costly.

Rugged Industrial Design: Constructed with an IP23-rated enclosure and anti-vibration mounting, the GE IS200VTURH2BAC withstands harsh environments, including high temperatures, humidity, and mechanical stress. Conformal-coated PCBs protect against dust and moisture, extending component lifespan.

Multi-Protocol Connectivity: With support for Modbus and Ethernet/IP, the module integrates seamlessly with legacy and modern control systems, enabling remote monitoring and diagnostics via SCADA platforms. This flexibility reduces integration complexity in multi-vendor setups.

Advanced Diagnostics: Built-in self-test functions and real-time health monitoring provide early detection of component degradation, allowing proactive maintenance. The module logs diagnostic data for post-fault analysis, minimizing mean time to repair (MTTR).

Application Areas

The GE IS200VTURH2BAC is widely deployed in industries requiring precise turbine control:

-

Power Generation:

- Controls steam turbines in thermal power plants, maintaining grid frequency and voltage stability during load changes.

- Manages gas turbines in combined cycle plants, optimizing energy efficiency and reducing emissions.

-

Oil and Gas:

- Regulates gas compressors in pipeline networks, ensuring consistent flow rates and pressure control.

- Controls steam turbines in refineries for process heating and power generation, supporting continuous operations.

-

Manufacturing:

- Drives steam turbines in paper mills and chemical plants, maintaining precise process temperatures and mechanical power.

- Integrates with cogeneration systems in food and beverage facilities, optimizing energy use for heating and power.

-

Marine and Offshore:

- Controls marine steam turbines for propulsion and power generation, withstanding harsh marine environments.

- Manages gas turbines in offshore platforms for power supply and compression systems.

Related Products

- GE IS200VPWRH1B: A redundant power supply module for the Mark VIe system, ensuring continuous operation of the GE IS200VTURH2BAC in critical applications.

- GE IS200VCMCH1B: A communication module that pairs with the GE IS200VTURH2BAC to enable Ethernet/IP connectivity with higher-level control systems.

- GE IS200VFNHH1B: A frequency input module for processing speed sensor signals, often used in conjunction with the GE IS200VTURH2BAC for turbine speed control.

- GE IS200VTBCH1B: A turbine protection module that works alongside the GE IS200VTURH2BAC to monitor and respond to abnormal turbine conditions.

- GE IS200VPLCH1B: A programmable logic controller module that expands the computational capabilities of the Mark VIe system when integrated with the GE IS200VTURH2BAC.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200VTURH2BAC, ensure the following:

Before installing the GE IS200VTURH2BAC, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control cabinet is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability.

- Use GE’s Proficy Machine Edition software to configure control loop parameters, alarm thresholds, and communication protocols based on turbine specifications.

- Mount the module in a 19″ rack with at least 50 mm of clearance for airflow, securing it with anti-vibration brackets to minimize mechanical stress.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for faults) and cleaning dust from ventilation slots using a non-conductive brush.

- Calibration: Annual calibration of analog inputs and outputs using certified test equipment to ensure measurement accuracy, particularly for speed and temperature sensors.

- Firmware Updates: Periodically update the module’s firmware via GE’s software to access new control algorithms and security patches, especially when integrating with newer turbine models.

- Redundancy Testing: Biannual functional tests of dual processors to ensure seamless failover in case of hardware anomalies, verifying system reliability.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200VTURH2BAC, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits abnormal control performance or functional defects. For discontinued models like the GE IS200VTURH2BAC, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services, including firmware upgrades and component-level repairs, to maintain your turbine control system’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data from GE’s official specifications and industry applications. For detailed operational guidelines, refer to the GE IS200VTURH2BAC user manual or contact our technical support team.

GE IS200ERIOH1ABB | Mark VIe Remote I/O Module | IS200ISBBG2AAB

GE IS200EROCH1ABB | Exciter Regulator Output Module | IS200JPDDG1AAA

GE IS200EXHSG3REC | Excitation Control Module | IS200EROCH1ABB

GE IS200JPDDG1AAA | Digital Input Module | IS200SPIDG1ABA

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IC697CPX928-FE Integrated protection device

GE IC697CPX935 Connecting module

GE IC697MDL671 Eddy current sensor

GE IC695CPU315-CD probe

GE IC695CRU320 Tachometer sensor

GE IC695CRU320-BB modbus card

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: