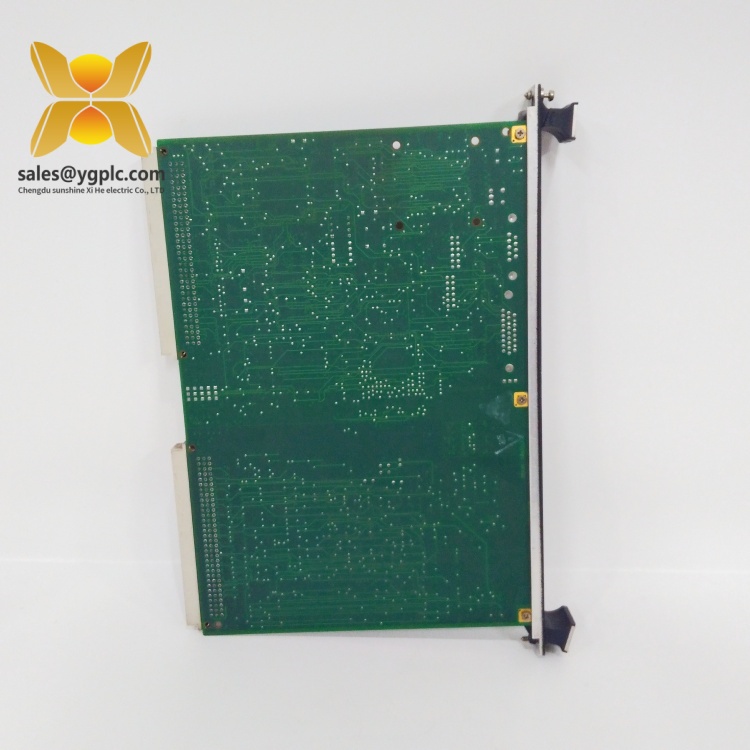

Description

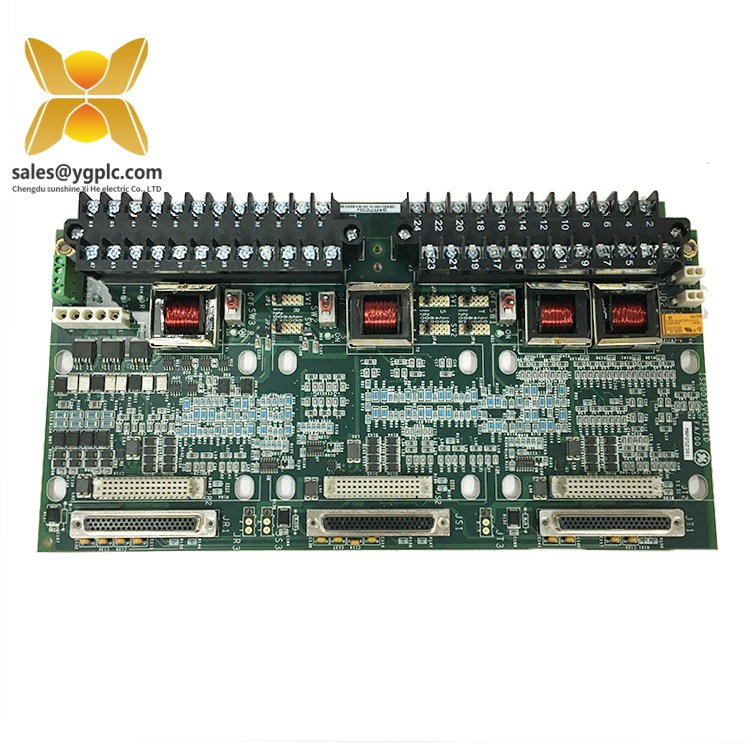

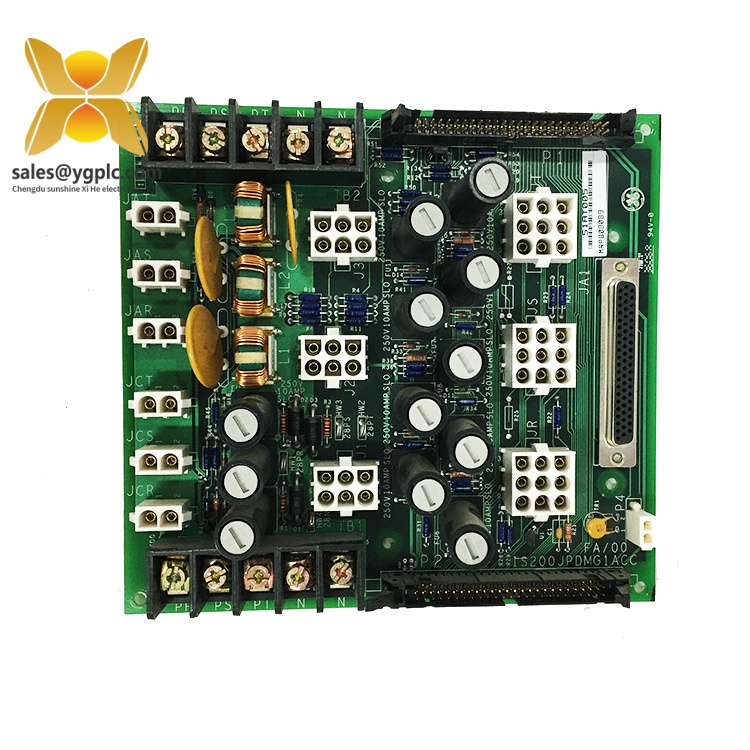

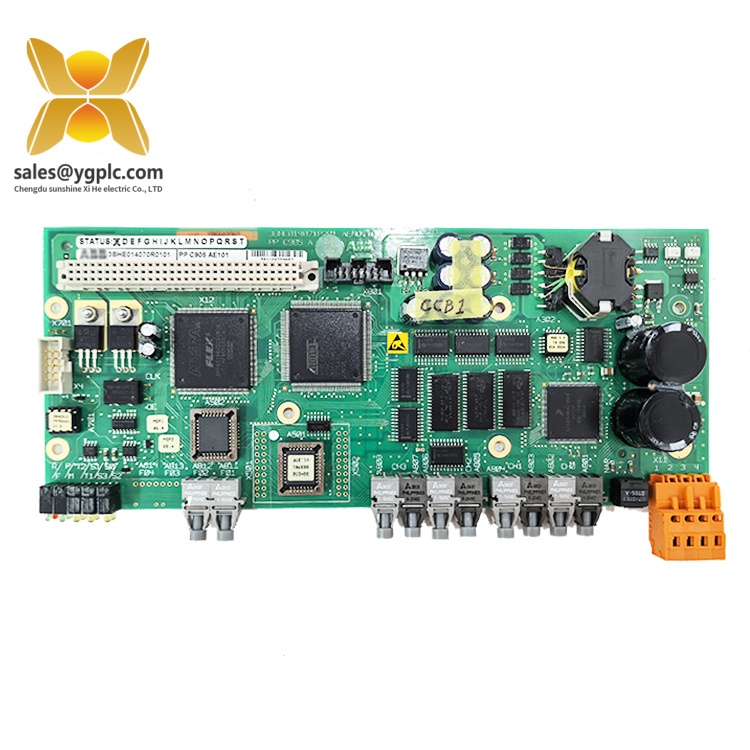

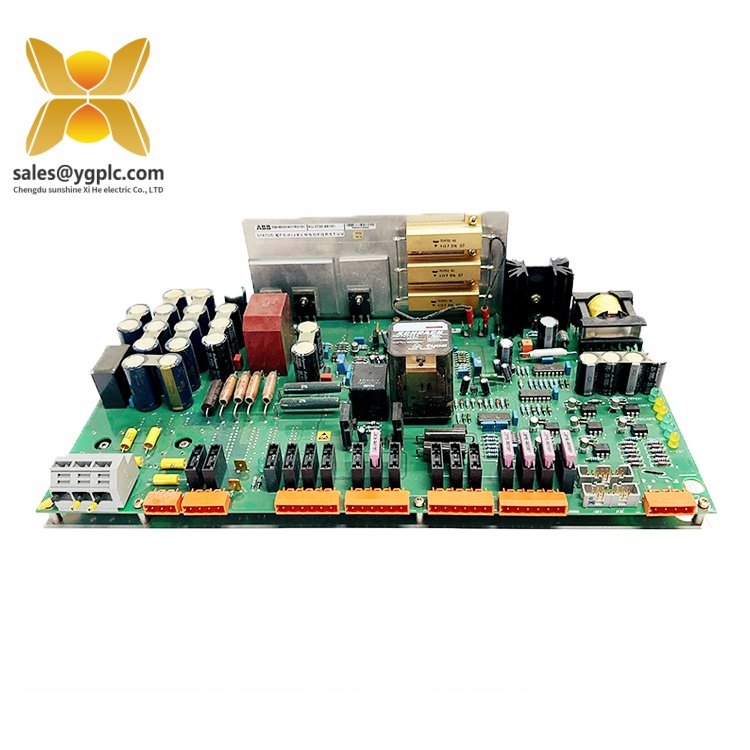

GE IS200VTURH1B Mark VI Primary Turbine Protection Board

Product Overview

The GE IS200VTURH1B is a high-reliability VME-based primary turbine protection board engineered for GE’s Mark VI Speedtronic distributed control system, specializing in mission-critical turbine applications across power generation, oil & gas, and marine propulsion. As a core component of the turbine protection system, this board ensures safe and reliable operation by monitoring key parameters, triggering overspeed trips, and managing flame detection in gas and steam turbines114.

Key functions include:

- Speed Monitoring: Processes signals from four passive magnetic speed sensors (2–20,000 Hz) to calculate turbine speed, using the median value for primary overspeed trip activation. This minimizes false trips caused by sensor noise114.

- Shaft Current/Voltage Protection: Monitors induced shaft currents/voltages, triggering alarms for excessive levels to prevent bearing damage.

- Flame Detection: Supports eight Geiger-Mueller flame detectors for gas turbine applications, requiring an external 335 V DC, 0.5 mA power supply114.

- Trip Control: Drives three primary overspeed trip relays on the TRPx terminal board, ensuring rapid actuation of emergency trip solenoids (ETDs) with sub-millisecond response times114.

- Zero-Speed Detection: Identifies turbine stoppage (2 RPM resolution) to enable automatic turning gear engagement.

Integrated into the Mark VI system, the IS200VTURH1B interfaces seamlessly with VME bus architecture and supports Triple Modular Redundancy (TMR) configurations, where three independent channels cross-validate signals to eliminate single-point failures. This makes it ideal for environments where downtime is catastrophic, such as offshore platforms and baseload power plants1314.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200VTURH1B |

| Manufacturer | GE |

| Product Type | VME Primary Turbine Protection Board |

| Series | Mark VI |

| Speed Inputs | 4x passive magnetic pickups (2–20,000 Hz) |

| Flame Detectors | 8x Geiger-Mueller sensors |

| Trip Relays | 3x primary overspeed trip relays (TRPx terminal board) |

| Communication | VME bus |

| Physical Dimensions | 43.1 cm (H) × 35.2 cm (W) × 5 cm (D) |

| Weight | 1.9 kg |

| Operating Temperature | -40°C to +70°C |

| Certifications | CE, UL 508, ATEX Zone 2 (IIC) |

| Power Requirements | 24 V DC ±10% (derived from Mark VI system power supply) |

| Mounting | 6U VME rack-mountable |

Main Features and Advantages

Rugged Turbine Protection:

The IS200VTURH1B integrates critical protection functions into a single VME card, including overspeed detection, shaft current monitoring, and flame safeguard. Its median speed signal processing ensures reliable protection in high-vibration environments by filtering out sensor anomalies114. The board’s conformal coating and MIL-STD-810G compliance protect against dust, moisture, and corrosive gases, making it suitable for offshore and industrial settings14.

High-Speed Trip Response:

With sub-millisecond trip actuation, the board rapidly disengages turbine power in overspeed scenarios, reducing mechanical stress and preventing catastrophic failure. This is vital for gas turbines operating at up to 30,000 RPM114. Each trip relay supports 0.5 A current, ensuring sufficient power to drive emergency solenoids.

TMR-Compliant Architecture:

Supports Triple Modular Redundancy (TMR) configurations, where three independent channels cross-validate signals to eliminate single-point failures. In TMR systems, the board interfaces with nine TRPx relays for voting logic, enhancing system resilience in safety-critical applications113.

Diagnostic Capabilities:

Front-panel LEDs indicate channel status, power health, and fault conditions. Built-in self-tests (BIST) verify circuit integrity, while real-time diagnostics are accessible via the Mark VI HMI (e.g., Cimplicity). This reduces mean time to repair (MTTR) by pinpointing faults like open circuits or shorted outputs114.

Hot-Swappable Design:

Enables field replacement without system shutdown, minimizing operational disruptions in 24/7 operations. This feature is particularly valuable in remote locations where maintenance access is limited114.

Application Areas

The GE IS200VTURH1B excels in industries requiring precise, reliable turbine control:

- Power Generation:

Protects gas and steam turbines in thermal and combined-cycle plants, ensuring safe startup/shutdown and grid synchronization. It manages generator circuit breakers and bypass systems during load changes114. - Oil & Gas:

Monitors compressors and pumps in offshore platforms and refineries, with ATEX certification for hazardous environments. It controls pipeline isolation valves and emergency shutdown (ESD) systems114. - Marine Propulsion:

Controls shipboard gas turbines, providing overspeed protection and flame detection for propulsion systems. Supports redundant configurations for naval and commercial vessels113. - Industrial Manufacturing:

Safeguards large steam turbines in chemical plants and steel mills, ensuring compliance with SIL 3 safety standards. It synchronizes conveyor belts and robotic arms in high-throughput production lines114.

Specific applications include turbine overspeed trip systems, flame safeguard systems for gas turbines, and shaft current monitoring in high-voltage environments.

Related Products

- GE IS200TTURH1B(Turbine Speed Input Board):

Provides speed signals to the IS200VTURH1B from magnetic pickups, supporting TMR configurations119. - GE IS200TRPGH1B(Turbine Protection Terminal Board):

Interfaces with flame detectors and trip solenoids, working in tandem with the IS200VTURH1B for gas turbine applications114. - GE IS200TRPLH1B(Turbine Protection Terminal Board):

Designed for steam turbines, it handles trip relay logic and ESD signals114. - GE IS215VPROH1B(VME Protection Module):

Redundant protection module for Mark VI systems, complementing the IS200VTURH1B in TMR setups314. - GE IS220PSCAH1A(Mark VI Power Supply):

Provides stable 24 V DC power to the IS200VTURH1B and other VME modules114. - GE IS200TRTDH1B(RTD Terminal Board):

Supports temperature monitoring for turbine components, feeding data to the IS200VTURH1B for closed-loop control23.

Installation and Maintenance

Pre-installation preparations:

Verify the VME rack is securely grounded and ventilated, with sufficient space for cooling. Install the IS200VTURH1B in a 6U VME slot, aligning it with the backplane. Connect shielded cables to the module’s terminals (J5 for speed inputs, TRPG for flame detectors), ensuring proper polarity for 24 V DC power. Configure speed thresholds and flame detection parameters via GE’s Proficy software, verifying TMR synchronization if applicable114.

Maintenance suggestions:

Perform quarterly firmware updates to ensure compatibility with the latest Mark VI software. Inspect front-panel LEDs monthly to confirm normal operation; address faults (e.g., red LEDs) using system diagnostics. Clean dust from vents biannually with compressed air, especially in dusty environments. Replace the module every 10 years or as recommended by GE’s lifecycle guidelines. Store spare IS200VTURH1B modules in anti-static packaging at 10–30°C with <50% humidity, testing them annually to validate functionality1714.

Product Guarantee

Our company offers a one-year quality warranty service for the IS200VTURH1B, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. As a leading import-export trade distribution company established in 2007 with 17 years of experience, we maintain large stocks of industrial control parts, including unpopular and discontinued models like the IS200VTURH1B, ensuring timely access for our customers.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

Note: The IS200VTURH1B is compatible with IS200TTURH1A/H1B and IS200TRPGH1A/H2A variants. Later models may require firmware adjustments for interoperability.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: